How to enhance formulation using rheology

contributed by Malvern Panalytical |

Using rheology to enhance formulation

Shona Murphy and Carolyn O Grady of Malvern Instruments discuss recent developments in the use of rheology to characterise and formulate foods.

Viscometers are used routinely to characterise food and drink products and offer simple, straightforward measurement for QC. They are also applied in formulation, but here rheology has far more to offer than simple viscosity measurements. Switching from a viscometer to a rheometer provides access to an extended range of test capabilities that can be used to accelerate and refine formulation to a more successful commercial solution.

Traditional barriers to fully exploiting the potential of rheology have been a lack of understanding regarding which test to apply and how to interpret the resulting data. Recent advances in the design and functionality of rheometers directly address these issues and make detailed, informative rheological studies more accessible. The following examples illustrate the potential rewards of exploiting these advances.

A more complete flow curve – extending viscosity measurements

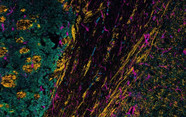

A defining principle of rheological characterisation is that the measurement conditions applied should reflect those to which the product will be subjected during use. A failure to meet this condition results in the need for extrapolation beyond the measurement range and this can be problematic, as illustrated by Figure 1. The blue shaded window represents a typical measurement range for a rotational viscometer (Bohlin Visco 88, Malvern Instruments) and clearly highlights the inability of a viscometer to fully capture the viscosity profile of a sample, particularly at the extremes of the shear rate range.

In QC, this limitation may be unimportant, since it may be sufficient to simply verify consistency by testing against a single point specification within the accessible measurement range. However, the same is not true for formulation, where understanding how the material behaves under a wide range of conditions helps to ensure optimal performance under all circumstances.

Log in or register to read this article in full and gain access to The Analytical Scientist’s entire content archive. It’s FREE!