Designing for Discovery

Laboratory design can be conducive – or unconducive – to creativity and productivity. Can today’s lab layout and rationale, a legacy from 60 years ago, be improved upon? I say yes, and go back even further in the history of the laboratory for inspiration.

As a lab manager, how can you boost vitality, promote collaboration and engender inspiration among your staff ? Here, Gregory Weddle describes how lab design can enhance the creative process to create your own ‘Maximum Lab’.

Laboratory use

In-Silico: Supports computerized modeling and analysis. Provides access to or contains the computer systems, desktop office/work areas, and collaborative space.

Free Thinking: For testing theory or converting chance observations into invention. Often a typical wet lab with support for a range of instrumentation.

Campaign: For testing and charting characteristics of identified compounds. Designed to move discovery as far as Phase I clinical trials.

Production: Supports production with assay tests, or for manufacture of products for development use.

Quality & Compliance: For testing of final product for potency, consistency, structure integrity, stability, etc.

Laboratory configurations

Open Lab: Typically houses specialty analytical instruments for use by multiple scientists, leveraging investment into key instrumentation. Requires high instrument uptime, easy instrument setup, teardown, cleaning and validation.

Flex Lab: Allows configuration changes based on scientific need without implemention of a complex facility modification project. Variable in the degree of flexibility, but normally allows basic movement of furniture and utilities.

Traditional Lab or Wet Lab: Constructed for a broad range of desktop experimentation. Designs are based on repetitive workstations of utilities (water, gases, waste path), and the safety of scientists. Majority based on classroom laboratory configurations from the early to mid 20th century.

| <b>Lab Use</b> | |||||||

|---|---|---|---|---|---|---|---|

| <b>In Silico</b> | Open | ||||||

| <b>Free Thinking</b> | Flex | ||||||

| <b>Campaign</b> | Flex | Open | |||||

| <b>Quality / Compliance</b> | Traditional | Flex | |||||

| <b>Production</b> | Traditional | Open | |||||

| <b>Chemical</b> | <b>Biochemical</b> | <b>Automation</b> | <b>Tissue Culture</b> | <b>Analytical</b> | <b>Development</b> | ||

| <b><i>Scientific Focus</i></b> | |||||||

While the range of equipment has expanded dramatically over the years, the laboratory’s raison d‘être is the same as it was in the days of Gregor Mendel (1822-1884), Thomas Edison (1847- 1931) and Alexander Fleming (1881-1955): experimentation. The lab provides the setting for scientists to observe the world and test the postulates of inspired minds in a repeatable manner. Walking through Thomas Edison’s lab in Michigan a few years ago, I wondered how he repeated anything at all. His main tools were his eyes, sketchpad, scales, and calipers; and most measurements were taken by devices invented by Edison or his technicians, leveraging math and science. Yet the basic structure required of his and other illustrious researchers’ workspaces is mirrored today (see sidebar,“Laboratory use”).

The in-silico lab equivalent in Mendel’s time was his desk: an oil lamp, paper, quill, and ink well. Bookcases were filled with every written reference he could get his hands on. His mind was the only computer he had at his disposal to decipher, in minute detail, his expectations and observations. For his free-thinking lab, Mendel had pots, calipers, a scalpel, some dirt and peas to test and prove his theories or, in some cases, to convert a chance or tangential observation into a new concept. In his campaign lab, Fleming worked on increasing mold harvests, proving and reproving concepts, and improving safety, purity and effect.

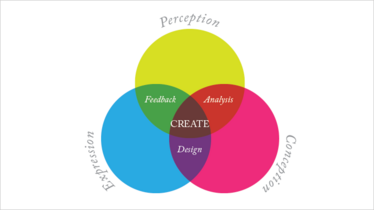

Mendel, Edison and Fleming were inspired to wonder: “What if ?”. How do we nurture that spirit today, and can the lab configuration contribute to it? My role is to work with clients to discern the needs or goals for a space, then to influence the design to most effectively support those goals. Whether the target is volume output, or an environment to capture perception, expression, or conception of thought that can lead to the creative processes (see Figure 1), we need to understand the impact of space on people.

Fig 1: Understanding creativity. Adapted from “How the Creative Process Works”, by Robert Lindsay Nathan, Ludwig von Mises Institute, 2009 (mises.org/daily/3461)

Understanding the creative process

Lab space, historically and today, is fashioned by the room available and what scientists had at their disposal: instruments, hand tools, assistants, desks, chemical and biological materials, power, gases, water, and so on. Safety was, at first, an individual responsibility; today we have engineers, architects, and environmental health and safety professionals looking out for our well-being.

The traditional lab of today was conceptually designed in the 1950s and 60s following academically-guided constructs. It provides us with the familiar stark environments and cramped storage, often with no thought for optimized or integrated technologies.Avi Hofstein and Vincent N.Lunetta’s work points to the lack of innovation in laboratory design in the academic environment and how those designs drove commercial lab spaces for the next 50 years (1). The pharmaceutical boom of the 1980s and 90s delivered millions of square feet of lab space following these outdated precepts.

Sadly, the creative process is imperiled in such environments. It is somewhat ironic that Big Pharma actually contributed to the lack of facility innovation as they attempted to create their own campuses and labs to reflect academic campus and labs, all with the idea of attracting new scientists to a familiar environment...

So, how do we design an environment to better support the creative process? Well, lab layouts and work areas must provide places to engage in each of the three phases of creativity: environments that support perception, conception and expression.That means providing the opportunity to draw on existing technologies, connect with other researchers and access information so that we don’t have to start from scratch; leveraging previous research; and offering a new view of the challenge. Therefore, work environments need to include the “wet lab” as well as “collaborative” and “contemplative” spaces.

Categorizing and designing

Just as the lab suite needs to support the creative process, we must also understand the design requirements of the wet and in-silico lab components. Much of the need here is defined by the phase and nature of the research. Chemical, biochemical, tissue culture, analytical and development research needs must all be clearly defined and documented. Further considerations include any need for open access and flex labs, and the requirements of workflows and instrumentation. Documentation of these needs, provided by scientists, the processes themselves, and instrument manufacturers must be integrated to achieve the optimal solution. Instrument providers tend to sell a single instrument and its capabilities; however, it is rarely a single instrument that determines the output or success of research. We must consider the impact of all instruments, technologies, and consumables within the workflow.

- A. Hofstein and V. N. Lunetta, “The Laboratory in Science Education: Foundations for the Twenty-First Century”, Sci. Ed., 88: 28–54 (2004). DOI: 10.1002/sce.10106

- Robert Lindsay Nathan, “How the Creative Process Works”, Ludwig von Mises Institute, 2009 (mises.org/daily/3461)

"My first engineering role out of Purdue University placed me in support of Indiana University's Cyclotron Particle accelerator, an experience and opportunity that laid the ground work for a world of innovative science and the facility needs and designs that support them." Greg Weddle is the global director of Life Science Advanced Solutions for Johnson Controls. In his 29 years with Johnson Controls, he has focused on developing turnkey facility management and automation solutions for the life sciences market. "Like my father and mother before me, I love to teach, and I served as guest instructor on the topic of Clean Room design for Purdue University's graduate program, and for the last nine years as an instructor for FDA's National training program, Office of Regulatory Affairs University.