Industrial Revelations: Theo Jelink, AkzoNobel Chemicals

In our ongoing series championing scientists in industry, we look at one chromatographer’s experience of innovation and knowledge transfer in the field of specialty chemicals.

Theo Jelink has worked at AkzoNobel Chemicals for almost 40 years. After a stint in the army, a series of speculative letters to chemical companies saw him gain a position in the Research, Development and Innovation (RD&I) Department of AzkoNobel, where the chance to experiment with multiple analytical tools soon had him hooked. Here, he tells us more about working with cutting-edge tech and the collaborative culture at the company.

What are the advantages of working in industry?

It is very challenging, but highly enjoyable. The scope of my company is broad and we have sites located all over the world, with colleagues from America to Japan, from Sweden to Africa. There are no borders these days with modern communication. Within our RD&I group, I come into contact with all kind of analytical techniques – challenging projects can often only be solved by multidisciplinary teams. Having close contact with our customers all over the world gives me the chance to meet people from other cultures, so I’ve ended up with a large, international network. I am also directly involved in the practical implementation of the solution within each project, which is a real highlight for me.

How would you characterize the culture in your area of work?

It is very open – a result of working in a real team-oriented environment. We have plenty of opportunities to keep up-to-date with developments in other fields, or with other techniques, via workshops, lectures, knowledge cafes, and so on. The chance to continually improve on your knowledge and develop your skills is positive and very important.

Tell us about your day-to-day…

It involves providing chromatographic solutions for incoming projects companywide, but also advising different customers about implementing chromatography systems in their laboratory or processes. I also try to implement chromatography as an on-line or at-line tool for many processes, and try to take the analytics to the customer – instead of bringing the customer to our lab.

Another responsibility for me is data management; I implemented the current data system in our laboratories and am now system administrator, responsible for maintaining and updating our system. I am currently rolling out the system in different locations across the site.

It is also my role to keep up-to-date with developments in my scientific field through regular and intensive contact with instrument suppliers – and this can lead to collaboration for the development of new instruments and testing prototypes. When it comes to potential investment opportunities for new technologies and instruments, I am often called on to advise about the best fit – based on testing and experience.

Can you give us an example of a collaborative project you’ve worked on?

Several years ago, I got a request from a specific business unit of our company to develop an instrument, one which would control a particular process, and perform analysis both at percentage level and at ppb level, simultaneously and at high speed. But the most challenging factor was it had to be controlled by someone without any knowledge of chromatography; the system needed to run unattended so it had to be fully automated. It took me several years to develop a special capillary analytical column and an automated setup, and it even involved a collaboration with glassblowing technicians and electronics departments. Ultimately, we were able to produce an instrument that fit every one of the stringent requirements.

What has been your biggest success so far?

One of my most successful projects was related to environmental analysis in one of our plants. I developed a method for personal air sampling to monitor the exposure of people in a plant to potentially toxic chemicals. The work resulted in a much better working environment for the operators, and great job satisfaction for me.

Are you working on any interesting projects at the moment?

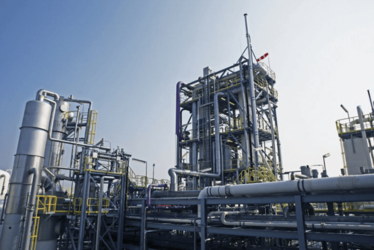

For me, the most interesting projects these days are those that implement “green” technology in our processes. Our code of conduct means that I am not allowed to share more about these developments right now, but the fact they are both necessary and challenging makes them exciting to work on.

Do you often get a chance to explore new initiatives?

In our department, we have a budget for development, which allows us to investigate trends in our scientific area. We also generate ideas through collaboration with instrument manufacturers and “brainstorming” sessions with other users worldwide. An example of this is the “Voice of the Customer” event organized by Thermo Fisher Scientific; customers from all over the world met in Milan to discuss the function of the autosamplers of the future. Another example is a collaboration with C2V (now Thermo), which makes micro-GCs using MEMS-based technology. We worked with them to test a prototype and made suggestions to improve the instrument. It feels good to be at the cutting edge!

How easy is knowledge transfer between industry and academic research environments?

It is sometimes difficult to organize because of the differences in culture and attitudes to “knowledge-sharing” in different countries and organizations. For example, within our company we have a “code of conduct” that each person has to sign, a way of preventing people sharing confidential details with people outside the organization. Most of the time, on-site cooperation is the best way to get things done.

What does the future hold for you?

My job continues to provide many challenges and a broad scope of projects. I have contact with a large network all over the world, and a great team to work with on-site. I get enjoyment from this job every day – so all I know is that I’d happily continue until the day I retire!

Theo Jelink has worked at AkzoNobel Chemicals for almost 40 years. After a stint in the army, a series of speculative letters to chemical companies saw him gain a position in the Research, Development and Innovation (RD&I) Department of AzkoNobel, where the chance to experiment with multiple analytical tools soon had him hooked.