Hyper-Fast GC - and a New World Perspective

In the past two years, we’ve moved on from beginner’s luck to results obtained through expertise. Our work is being received with increasing enthusiasm, and we’ve even claimed the top spot on The Analytical Scientist Innovation Awards 2018. However, the story of field flow thermal gradient gas chromatography is far from over.

It is a shame that I cannot tell a truly heroic story about the development of our technology. Sometimes, start-up stories seem almost mythical: the inventors are smarter than everyone around them and fight their way through all the difficulties and bitter setbacks into a bright future! Maybe these stories really exist, but the development of HyperChrom is more of a longlasting effort – and with less drama!

When I told the first part of the flow field thermal gradient gas chromatography (FF-TG-GC) story – “Beginner’s Luck and Hyper-fast GC” – in The Analytical Scientist after Riva 2016, I chose luck and ignorance as leitmotifs (1). Luck has continued to play a big role; fortunately, ignorance is in slow decline! For this article, I was asked to write a retrospective of the last couple of years. Certainly, a lot has happened, but much more is still unclear and the future remains uncertain... So how can I draw any real conclusions before the end of our story?

Today, we have five years of technology development and a lot of experience behind us. And, although this is a short time compared with many colleagues in the field, we now better understand many of the complex processes involved in GC. To really test a new idea, it takes a great deal of stamina. When I look back at the chromatograms produced by our first experimental setups, I seriously wonder why we didn’t give up! The resolution was far from the published results of other researchers and commercial companies. Ultimately, however, curiosity got the better of us; the incentive to finally see the expected benefit of a temperature gradient was simply too strong. What’s more, our developmental journey has been consistently positive, with a constant flow of new improvements, ideas and technology – a wonderful way to work. Thus, we finally reached the preliminary peak in developing temperature gradient GC... and towards the end of 2018, we were awarded the top spot in The Analytical Scientist Innovation Awards!

During my doctorate, I studied the philosophy of science and epistemology, which has allowed me to observe my own modus operandi – and though that may sound a little strange, it teaches patience. It takes a great deal of time and experience to gain a real understanding of complex processes (and high-level GC is really complicated), but when one has reached this state – you might call it inner representation – interrelations and new solutions emerge intuitively and creativity can unfold much more effectively. Even scientists and engineers need philosophy!

Technical development

I don’t know exactly how technical development is organized in larger companies. I imagine that groups work on very structured projects that are well planned and well managed. The small HyperChrom team can’t match that. What does our approach look like? My working day at the Institute for agricultural Engineering at the University of Bonn almost always begins with a visit to the mechanical workshop, not the laboratory. There, I sit down with our precision mechanic and self-taught designer Wilfried Berchtold. He doesn’t always have as much time as I would like, as he also has to design and build large agricultural machines for scientific experiments. When he has time, however, a very creative phase always begins. Most of the time I have hatched new ideas, which we then discuss with a view to realization (and reject some crazy ideas). Wilfried is a guru when it comes to manufacturing processes and can design in such a way that even delicate parts can be produced. Furthermore, he makes sure that anything he designs also looks beautiful!

To exploit the full potential of fast GC, great design is required. Even small errors (for example, cold spots, dead volumes, leakages) lead to dramatic deviations from the ideal behavior, masking possible progress. That’s why an excellent scientific workshop – and someone like Wilfried – are so extremely important!

A large part of the technical development of HyperChrom GC is not as obvious as the mechanical components would lead you to believe. Behind the gray aluminum plates, electronics, microcontrollers and firmware are hiding. Here, luck played a big role again. In my e-nose days (around 2003), I met a physicist and technology developer called Martin Theisen. He develops and builds very complicated devices, from medical to superconductivity. Three years ago, we met again and he started to develop a commercial device from the concept of the FFTG-GC. The result was brilliant - and much better than I had dreamed! When I was already satisfied with something, Martin always found an even better solution – often leading to new measurement methods and new possibilities in chromatography.

Martin has coupled multiple multicore microcontrollers with a dedicated bus to synchronize all controls in real time. And that allows each sub-process to run on its own processor core without latency. The temperature control of the column temperature is incredibly fast and precise. The pressure controls also come from our own development efforts, as the control speed requirements are much higher than with existing GCs. When we were unable to obtain a fan with a speed that could be precisely controlled, Martin developed it himself, with its own processor and a brushless precision motor.

Of course, even the best hardware in GC is only one side of the coin. After my visit to the workshop in the morning, I go to the laboratory to spend time with my colleagues – Jan Leppert, Peter Müller, Miriam Schäfers and Marco Aust. The working group is now larger: four scientists and a technician! Sometimes we see an unexpected tailing in the chromatograms, sometimes there are persistent carry-overs. Or a mass spectrometer shows strange artifacts in the signals. Just the daily problems of analysts everywhere. We must always focus on drawing the right conclusions so that we can improve our designs. And that means you first need to understand the problems – very challenging with a highly complex processes like GC.

Theory and modelling

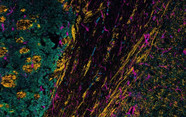

It is already a running gag at conferences: Leonid Blumberg, the great theoretician of chromatography, denies the benefits of temperature gradients. This was the case at Riva 2016 and also explicitly at Riva 2018, during his lecture for the Marcel Golay Award. But Leonid would not be the excellent scientist he is if he were not open to a possible revision of this view. And so, Leonid is now helping my colleague and physicist Jan Leppert to settle the debate on the basis of theory and a simulation model. Jan has already created a complete simulation model that precisely reproduces the results of established models, but also takes the temperature gradient into account during the simulation (2).

I sometimes think that numerical models are only necessary for scientists who are too stupid to develop analytical solutions. Because of the enormous possibilities of fast computers, highly differentiated numerical models are now possible. But what about the efforts of our scientific predecessors of the pre-computer era – where the development of analytical solutions was associated with intelligent simplification? Such simplification can get lost in the computer-driven complexity. On the other hand, simplification can also lead to the loss of essential elements... In this area of conflict, we will re-evaluate the many open questions in the field of thermal gradient GC.

Virtual experimentation with a simulation model is in fact an independent area of research. The model must be very well validated and able to reproduce the physical–chemical processes of GC with the required level of detail. Yet, the computing time for the simulation of hyper-fast GC is even longer than a measurement would take!

A new world of analytics

Science philosopher Thomas S. Kuhn has described how innovations in science can create a new world perspective. Thermal gradient GC gives us an inkling of what that might feel like.

The possibilities of temperature gradient GC originally led us to start developing a HyperChrom, but at the same time, we wanted to build a system that was as easy to use as a conventional GC, could use any separation column, and did not require complicated and expensive modules or consumables. As university scientists with a small and ever-decreasing budget for consumables, we also had our colleagues in mind. All of these demands led us to the flow field principle.

The development, however, has gathered momentum of its own, which has led to many further improvements. In the meantime, HyperChrom FF-TG-GC has become a separate field of GC.

To enable exchange of the separation columns, we had to integrate connectors into the analytical pathway, which automatically provides us with a guard column between the injector and the separation column and a restriction to the detector. But we have found that no commercial GC connector is good enough for very narrow peaks. The minimal dead volumes always lead to peak tailing. Also, these connectors are often very delicate to assemble, with tight tolerances between missing leak tightness and column breakage due to excessive connection tightening. Therefore, we had to find our own solution: purged connectors.

Purged connectors posed a new challenge. To generate purging flows in the correct order of magnitude, an exact calculation of the pressures and flows at all junctions is necessary. It is good that we had already solved this problem for the Deans’ Switch (3). The electronic pressure controls (EPCs) also had to be designed with special manifolds and additional restrictions. These proprietary developments are all precisely adapted to the conditions and requirements of fast GC – and integrated into the new HyperChrom GC.

The transformation from conventional – slow – GC to very fast GC also requires new thinking in method development. Do the old methods really only have to be translated (4)? Does a one-to-one translation to drastically shortened times make sense at all? Measurement cycles that are shortened by a factor of 20–30 (including cooling) open up new opportunities for method development. Even a double measurement of the same sample requires only 2 min. Different sample quantities or concentrations can be injected to compensate for the lower sample capacity of microbore columns. Alternatively, two different temperature and gradient programs can be used to separate different critical pairs.

Since 10 conventional GC-MS instruments can easily be replaced at the same sample throughput, a particularly powerful mass spectrometer on a high-throughput GC is much more worthwhile. And that allows residual deficits in chromatographic resolution to be compensated by deconvolution or by measuring exact masses.

Key customers

How can technical developments be made without future customers? Again, we were lucky. Our first customer was a global petrochemical group, our second customer one of the world’s largest laboratory companies.

It’s not the big names that are important, though – it’s the people behind them. Everyone in the scientific community knows Jan Blomberg from his many contributions to chromatography and GC×GC, and Jan did much to encourage us at an early stage. Of course, we all know what challenges lie ahead of the HyperChrom-GC before it can be used in chemical production processes – but we believe we have made a strong start and the positive feedback from customers is highly motivating.

Beyond the scientific community, we found an extremely experienced analyst at our laboratory company customer. Manfred Lux was the first to open our eyes to the world of high-throughput laboratory analysis. The challenge of delivering high analytical quality with thousands of samples is huge. It’s a miracle how this is even possible, given the ever-changing samples and unavoidable technical malfunctions!

Manfred’s experience was invaluable in showing us how non-discriminatory sample injections are possible, and which components and materials deliver the best results. GC is also an empirical science!

The benefit of perspective

I came to GC relatively recently and one of the advantages of being an “outsider” is a different perspective – the ability to see things that are unfiltered by experience.

I am still amazed at how shortcomings in analytical technology lead to major problems and yet are accepted day in, day out! For example, with the injector: why do we have to be constantly annoyed by septum particles that fall into the liner, especially during solid-phase microextraction (SPME) measurements? Why do we have to endure septa that start to leak? Do outgassings of a new liner O-ring really have to appear in the chromatogram?

I have been collecting designs for septumless techniques for quite some time, and I am trying to understand their advantages and disadvantages. Additionally, I am open to dialogue with colleagues who have experience with septumless techniques. Even if the problem will be (very) difficult to solve to perfection, a novel septumless injector is worth the effort!

Another big focus of our future efforts will be in multidimensional technologies – with the modulation outside the GC oven and with our fast GC as the second dimension. The gas pulse modulation is especially interesting, which the highly innovative Robert Synovec presented to us in Riva in 2018 (5). It would be fantastic to combine this with fast GC...

We will also continue to work intensively in the field of simulation, not so much to compete with the excellent web-based simulation “Pro EZGC” from Restek, but to better understand the possibilities of gradient GC and to develop new measurement methods.

I am not daunted by the fact that GC is considered by many to be a “mature” technology – we will continue to work on further improvements for a long time to come!

- P Boeker, “Beginner’s Luck and Hyper-fast GC”, The Analytical Scientist, 0916, 38–42 (2016). theanalyticalscientist.com/techniques-tools/beginners-luck-and-hyper-fast-gc

- J Leppert et al, “Hyperfast flow-field thermal gradient GC/MS of explosives with reduced elution temperatures”, Anal Chem, 90, 8404–11 (2018). DOI: 10.1021/acs.analchem.8b00900

- P Boeker et al, “Comprehensive theory of the Deans’ switch as a variable flow splitter: fluid mechanics, mass balance, and system behavior”, Anal Chem, 85, 9021–30 (2013). DOI: 10.1021/ac401419j

- LM Blumberg and MS Klee, “Method translation and retention time locking in partition GC”, Anal Chem, 70, 3828–39 (1998). DOI: 10.1021/ac971141v

- DH Bahaghighat et al, “Ultrafast separations via pulse flow valve modulation to enable high peak capacity multidimensional gas chromatography”, J Chromatogr A, 1573, 115–24 (2018). DOI: 10.1016/j.chroma.2018.08.001

Peter Boeker is a research associate at the Institute of Agricultural Engineering, University of Bonn, Germany.