Introduction

A high throughput process for the preparation and testing of samples for their surface tension using the epMotion 5075 Liquid handling platform and Kibron delta-8 tensiometer has been successfully developed and implemented at the Centre for Materials Discovery. This allows multiple samples to be rapidly screened with a high accuracy, reproducibility and on a more cost effective scale. The process was shown to be over 500 times faster than manual traditional methods and allows swift studies to be carried out of formulation in the inks, surfactants, polymers, pharmaceutical and household care industries.

Understanding the surface tension properties of aqueous surfactants and polymer materials is important for the pharmaceutical, inks, surfactant and household products industries. The traditional method of measuring surface tension is time-consuming so only a few compounds can be measured by a single user per day. The following technical note explains the background behind the measurement of surface tension and the manor in which a high throughput process for conducting this measurement was developed.

Background

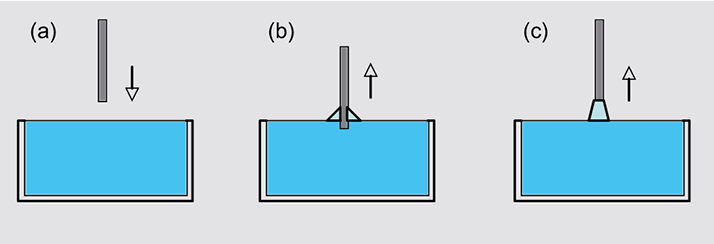

The traditional technique used to analyse surface tension is based on the measurement of the force of the interaction between a probe and a surface of a fluid using a tensiometer. The probe used in these experiments is suspended from a balance and brought into contact with the interface of liquid to be tested. The forces measured by the balance as the probe interacts with the surface of the liquid can be used to calculate surface tension. Factors affecting the forces in these measurements are: size and shape of the probe, contact angle of the liquid/solid interaction and the surface tension of the liquid. Some of these factors can easily be controlled such as the size and shape of the probe. Also a contact angle of zero is achieved by using probes made of a platinum/iridium alloy which insures complete wetting and easy and reliable cleaning. The maximum pull force method used by the Kibron Delta 8 tensiometer (see figure 1) to measure surface tension is achieved by: (a) immersing a thin rod into the sample, (b) the vertical retrieval of the rod and (c) the measurement of maximum force needed to remove the rod from the liquid [1, 2]. The technique requires a calibration factor obtained by measuring a liquid of known surface tension. In the case of the Kibron Delta 8 pure water is used to calibrate the instrument and used as a control in each place.

Figure 1: Diagram illustrating the maximum force method for surface tension measurement.

Figure 1: Diagram illustrating the maximum force method for surface tension measurement.