Background

Even as advances in engineering technologies and manufacturing processes have lowered the cost to make and distribute products, the demand for continued improvement is as strong as ever. In an environment where small improvements in characterization of raw materials or subtle changes in process parameters can result in significant production savings, the ability to design faster, smarter and more robust instrumentation is paramount.

Measurement Conditions

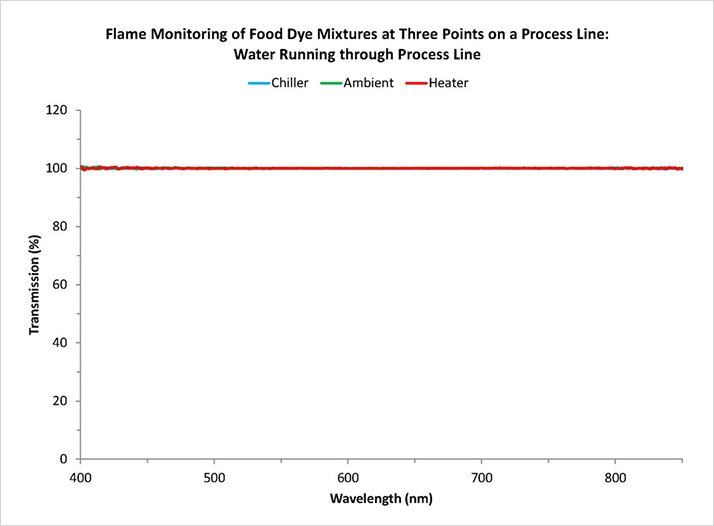

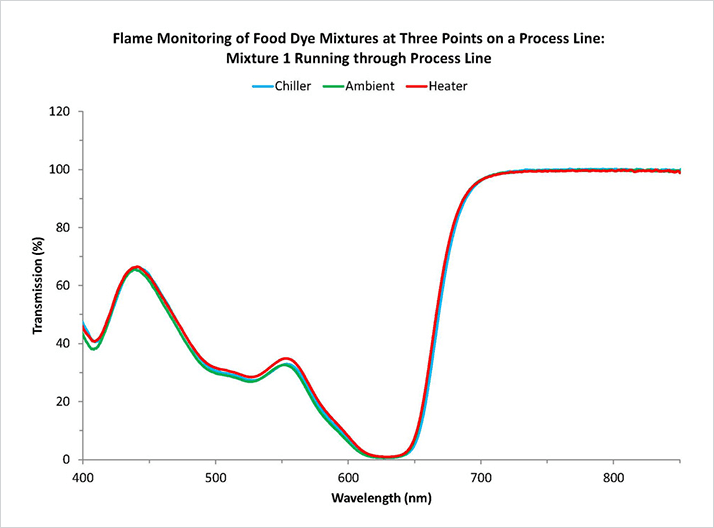

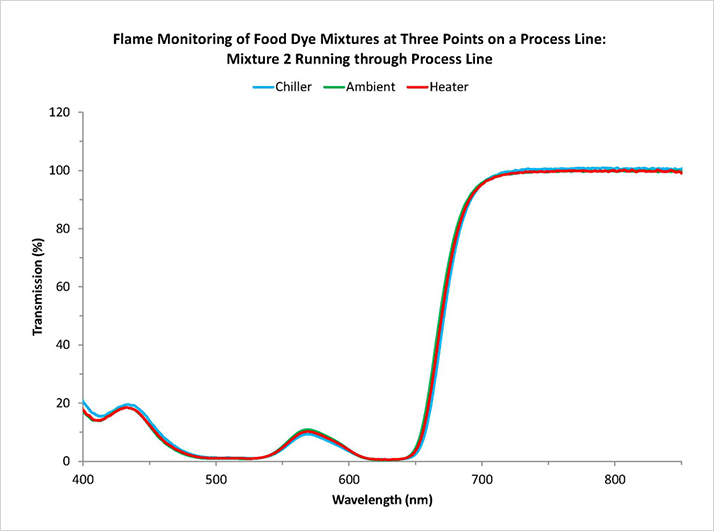

To evaluate the effectiveness of the Flame spectrometer at different temperatures, we measured transmission of several concentration levels of food dye mixtures on a simulated process line with simulated conditions encountered in a process environment. Then we isolated each Flame spectrometer in a different temperature environment – cool (using a chiller), ambient and hot (using a lab heater). Several sample mixtures were prepared for testing, using the Z-type flow cell to move each sample through the system. Water moving through the flow cell was measured as a reference (Figure 1).

Results

Although the Flame spectrometers measured the transmission of the mixtures flowing through the system at different temperature conditions, the resulting spectra – and sample composition information derived from the spectra – were nearly identical (Figures 2, 3). This result is significant for process line applications, where temperatures can vary from zone to zone within the stream. For quality control professionals, getting the correct answers under all sorts of conditions -- including temperature extremes -- is critical.

Conclusions

Process environments can be harsh, with extremes in temperature and humidity, and the harmful effects of dust and vibration. That’s why process-ready spectroscopic instrumentation such as Flame has been designed with few moving parts, has a high degree of thermal stability, and is easily adapted for different setups. The availability of such robust, repeatable, thermally stable instrumentation allows manufacturers to assess sample quality online at multiple points in processes, helping to improve yields, eliminate waste and reduce costs.Contact Information

Tel: +1 727 733 2447Email: Info@OceanOptics.com