What is a “Specialty Carbon Adsorbent”?

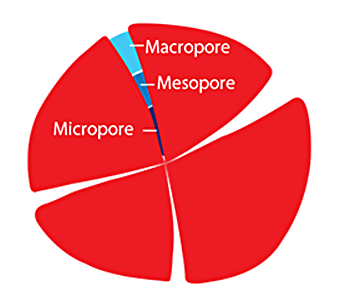

A graphic depicting a spherical particle is shown in Figure 1. Controlling pore composition is very important as it determines the adsorption and desorption characteristics of the particle. There are three types of pores relevant to carbon adsorbents. A macropore has a >500 Å diameter, a mesopore has a 20–500 Å diameter, and a micropore has a <20 Å diameter.

Unlike non-specific, low-tech carbon black and activated carbon adsorbents, our specialty carbon adsorbents are highly engineered materials, many manufactured from highly pure synthetic polymers. They can be designed with:

- The shape we want, either spherical or granular

- No pores, or more/less of any pore type to serve a specific purpose

- Tapered pores (from macro to meso to micro) which increase thermodynamic and kinetic efficiency

- A through-pore or closed-pore structure, which influences microporous strength and kinetic effectiveness

- Surface pH adjustments, as low as 2.5 to as high as 10.5

Today, we make over 30 different specialty carbon adsorbents, including Carbon Molecular Sieve (CMS), Spherical Graphitized Polymer Carbon (SGPC), and Graphitized Carbon Black (GCB) adsorbents. Any modifications (activation, oxidation, graphitization, surface pH adjustment, etc.) are accomplished through physical means, not chemical means.

Figure 1. Spherical Particle

Figure 1. Spherical Particle