Epoxy resin is a type of synthetic resin that could be used in a wide range of applications such as adhesives, coatings and fluxes, which require varieties of engineered curing kinetics and glass transition temperatures. The versatility of these epoxy resin systems arises from combining the epoxy resin with a co-reactant, called hardener, into a twocomponent epoxy. To make the precision control of the epoxy to hardener ratio, modern delivery systems package each component separately at a pre-defined volume. However, it is always a challenge in R&D and QA/QC to measure the epoxy to hardener ratio from cured epoxy to certify the optimized ratio. This application note presents a novel method to quantify the epoxy to hardener ratio from cured two component epoxy by using a pyrolyzer coupled to a GC/MS system.

Experimental Setup

In this example, 3,4-Epoxycyclohexylmethyl 3,4- epoxy cyclohexane carboxylate is picked as the epoxy resin, and methylhexahydrophthalic anhydride (MHHPA) is used as the hardener. Standards of epoxy to hardener were prepared in ratios of 0.50, 0.66, and 1.00. These standards were pyrolyzed using a CDS 6150 Pyroprobe. Peaks representing epoxy and hardener were chosen to calculate area ratios for a calibration curve.

Pyroprobe Setpoints:

Pyrolysis: 700°C 15 seconds

Interface: 300°C

Transfer Line: 325°C

Valve oven: 325°C

Transfer Line: 300°C

Valve Oven: 300°C

GC-MS

Column: 5% phenyl

(30m x 0.25mm)

Carrier: Helium, 1.00mL/min

75:1 split

Injector: 300°C

Oven: 40°C for 2 minutes

10°C/min to 325°C

Ion Source: 230°C

Mass Range: 35-600 amu

Results and Discussion

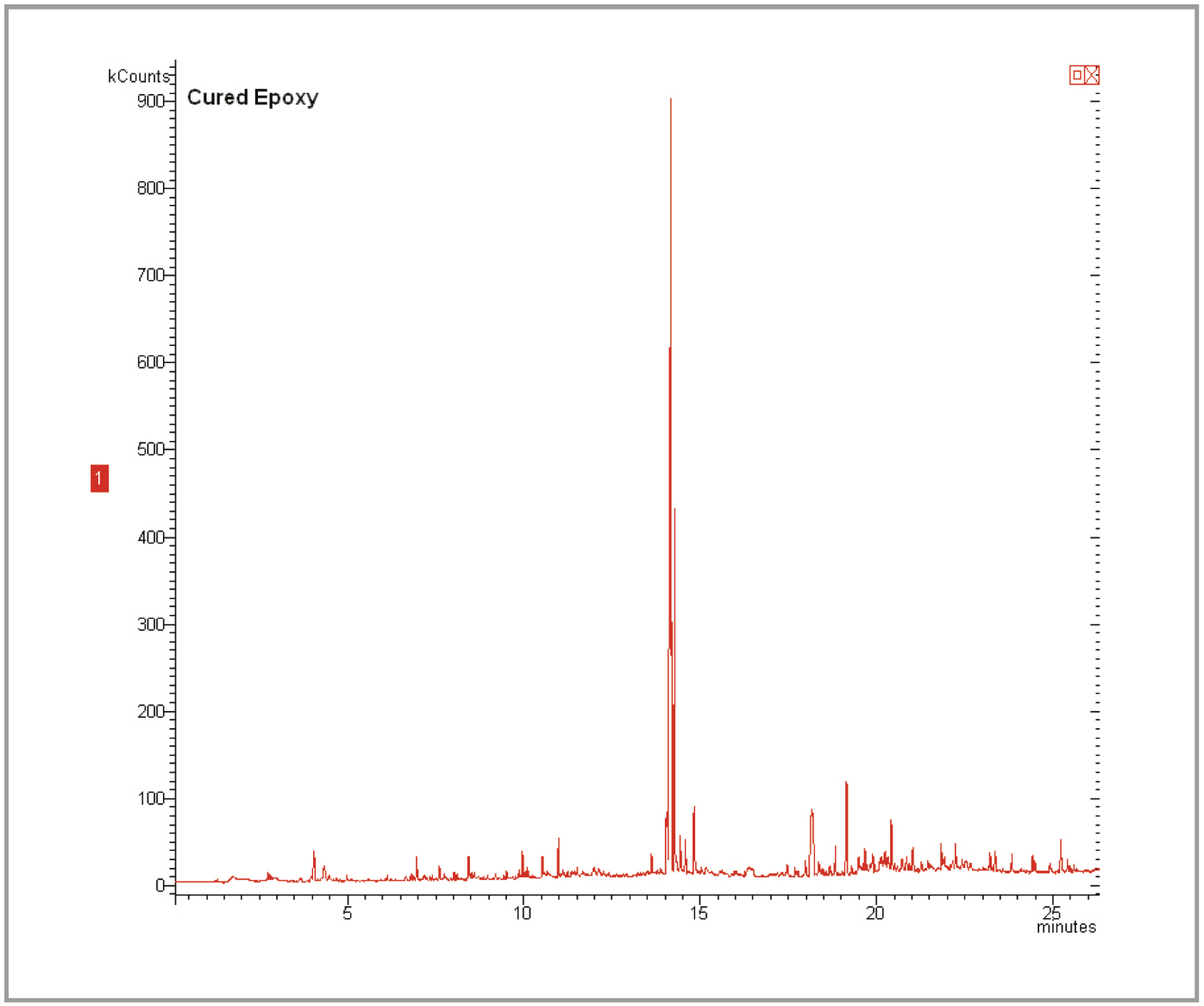

When pyrolyzed, the cured epoxy produces a pyrogram in which most of the components elute around 14 minutes (Figure 1).

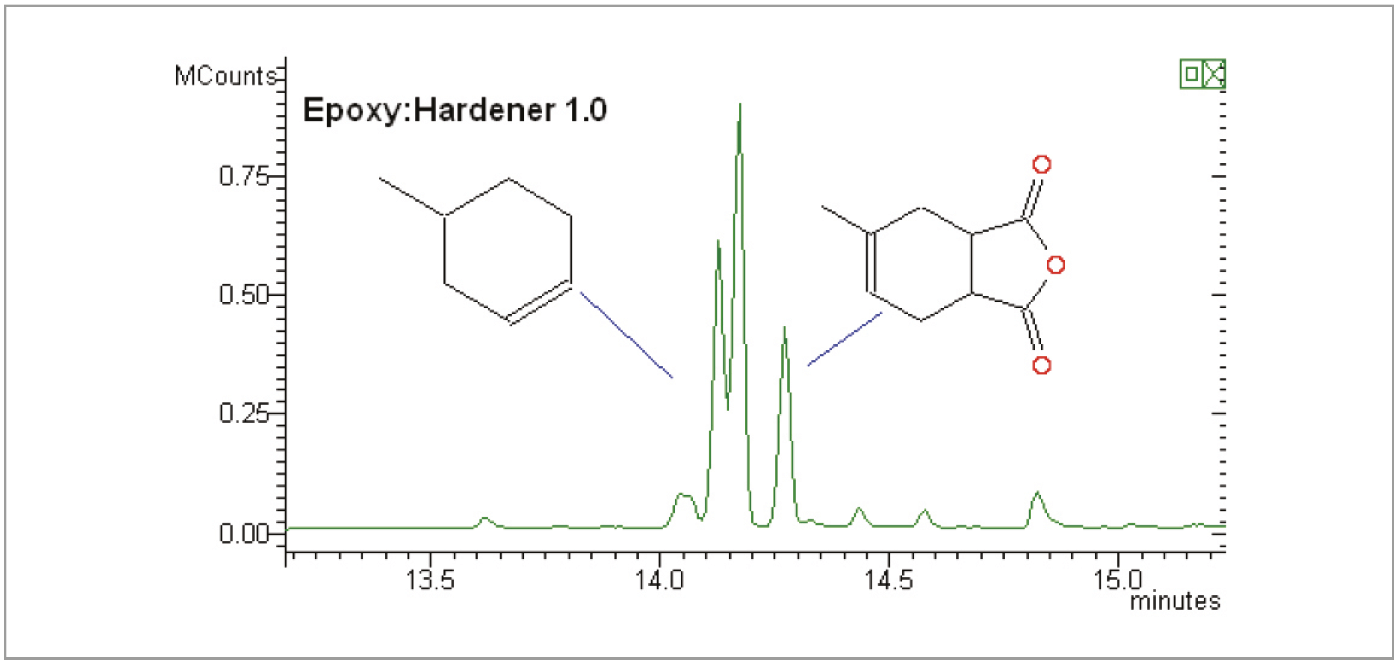

Peaks in this epoxy could be ascribed to either epoxy or hardener. Figure 2 shows an expanded view of one epoxy sample with epoxy to hardener ratios at 1.0.

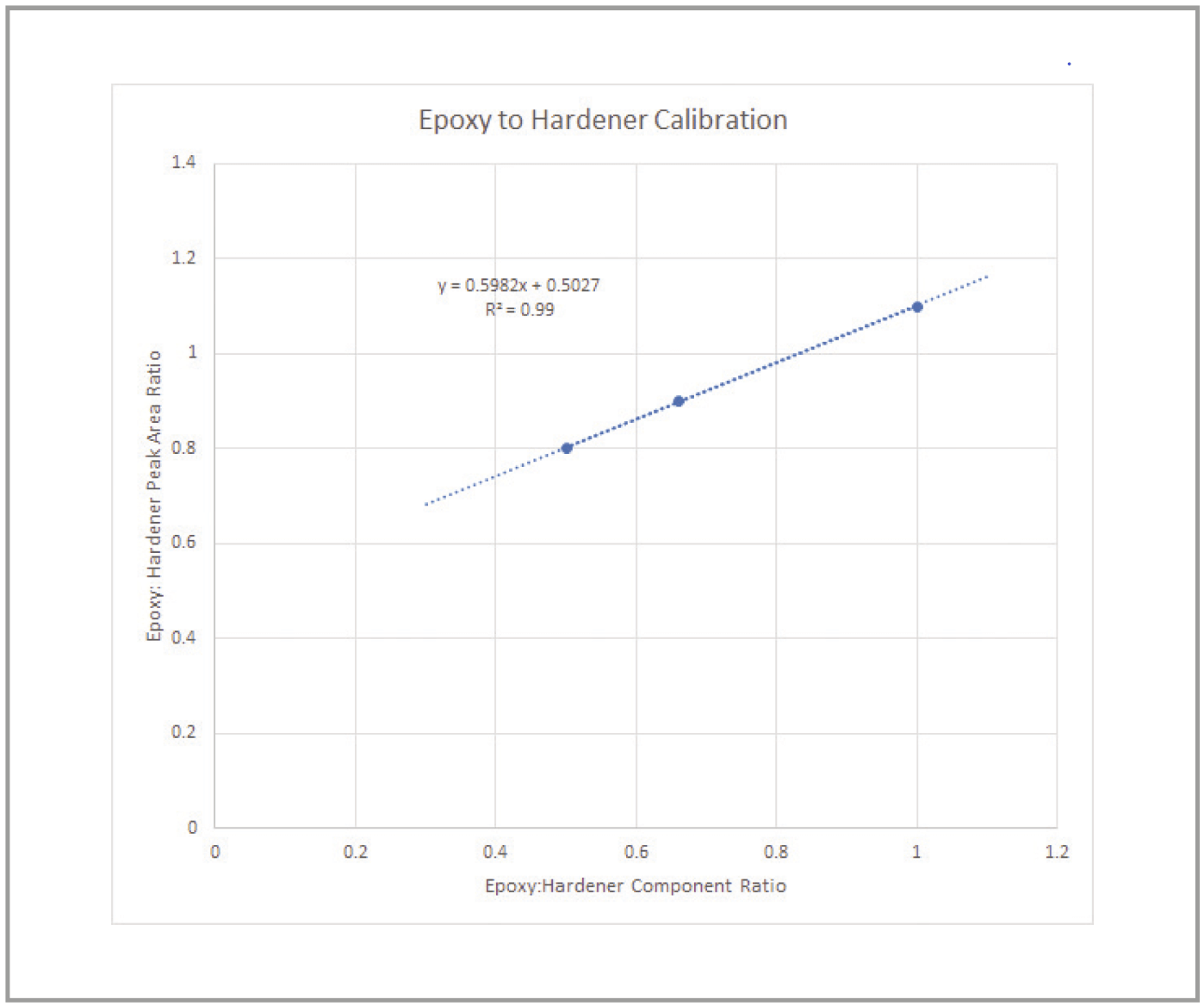

Matching the first peak to epoxy resin, and the third peak to hardener, peak area ratios were plotted against the relative amounts of the constituents. This generated a linear calibration curve which could be used to ascertain mix ratios of unknown resins as shown in Figure 3.

From the data fitting, the coefficient of determination was observed at 0.99. This linearity demonstrated that the Pyroprobe can provide quantitative analysis to determine epoxy to hardener component ratios.

Contact name: Dana Arnold

Contact Phone Number: (610) 932-3636