The current generation of solid core particles for LC analysis were introduced in 2006 and provide higher efficiency separations than equivalently sized fully porous particles. Since then, their use for the analysis of both small and large molecules has increased steadily, in a wide variety of analytical fields, to drive high performance separations and increases in laboratory throughput. This article focusses on the application of solid core particles to small molecule analysis. It begins by introducing the concept of solid core particles, their morphology, history of development and current methods of synthesis, before moving on to discuss the theory behind the performance advantages they offer. The Avantor® ACE® UltraCore range is then introduced, which combines solid core silica particles and a range of novel selectivity stationary phase chemistries. Finally, example applications that demonstrate how these particles can be used to provide solutions for some of the analytical challenges faced by the modern chromatography laboratory are discussed.

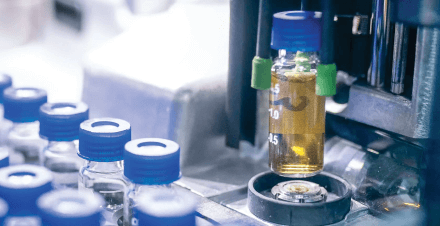

Chromatography is a separation technique based on adsorption and/or interaction of a mixture of different molecules with stationary phases. Among different types of chromatography, high performance liquid chromatography (HPLC) has been most widely used as an essential analysis tool for research, manufacturing, environmental monitoring and drug development.1 This is due to its universal applicability and remarkable assay precision.2 The silica microsphere is the dominant base architecture for stationary phases found in HPLC, although other materials based on organic polymers and other structures such as monolithic and irregular shaped beads are also available. The challenges that are faced in performing HPLC are best suited by this particle, which is stable in a wide range of aqueous and organic mobile phases, relatively cheap, amenable to a wide range of chemistry modifications, as well as being physically stable to the pressures that are seen within a typical separation process. The spherical nature of the bead has advantages in both the manufacturing process, in ensuring the generation of homogeneous particles, and in ensuring optimal chromatographic performance by minimising the dispersion processes occurring in the column.

For small nonporous particles, the separation is performed on the particle surface and band-broadening is alleviated because of the short diffusion path, thus allowing faster mass transfer.3 However, due to the low surface area, separation resolution and selectivity are limited. The surface area can be dramatically increased, up to 100-fold, by the introduction of pores into the main bead structure. For liquid phase separation, the pore sizes are required to be greater than ~ 7 nm to allow sufficient mass transport. For separation of large biomolecules, large pores up to 1000 Å may be required for efficient separation.4