Mineral oil hydrocarbons (MOH) are widely used as lubricants and may contain carcinogenic and mutagenic impurities. Hence food safety authorities require that ingredients, finished products, and packaging materials be tested. Comprehensive analysis of MOH utilizes a combined liquid and gas chromatography procedure, which is very challenging and time consuming. This article demonstrates that automated headspace-SIFT-MS analysis has potential to screen larger numbers of packaging samples – over 220 per day – for the volatile MOH fraction, providing a rapid indication of packaging material contamination. Moreover, SIFT-MS can simultaneously quantifies benzene contamination – addressing this recently identified need for personal care products (PCPs).

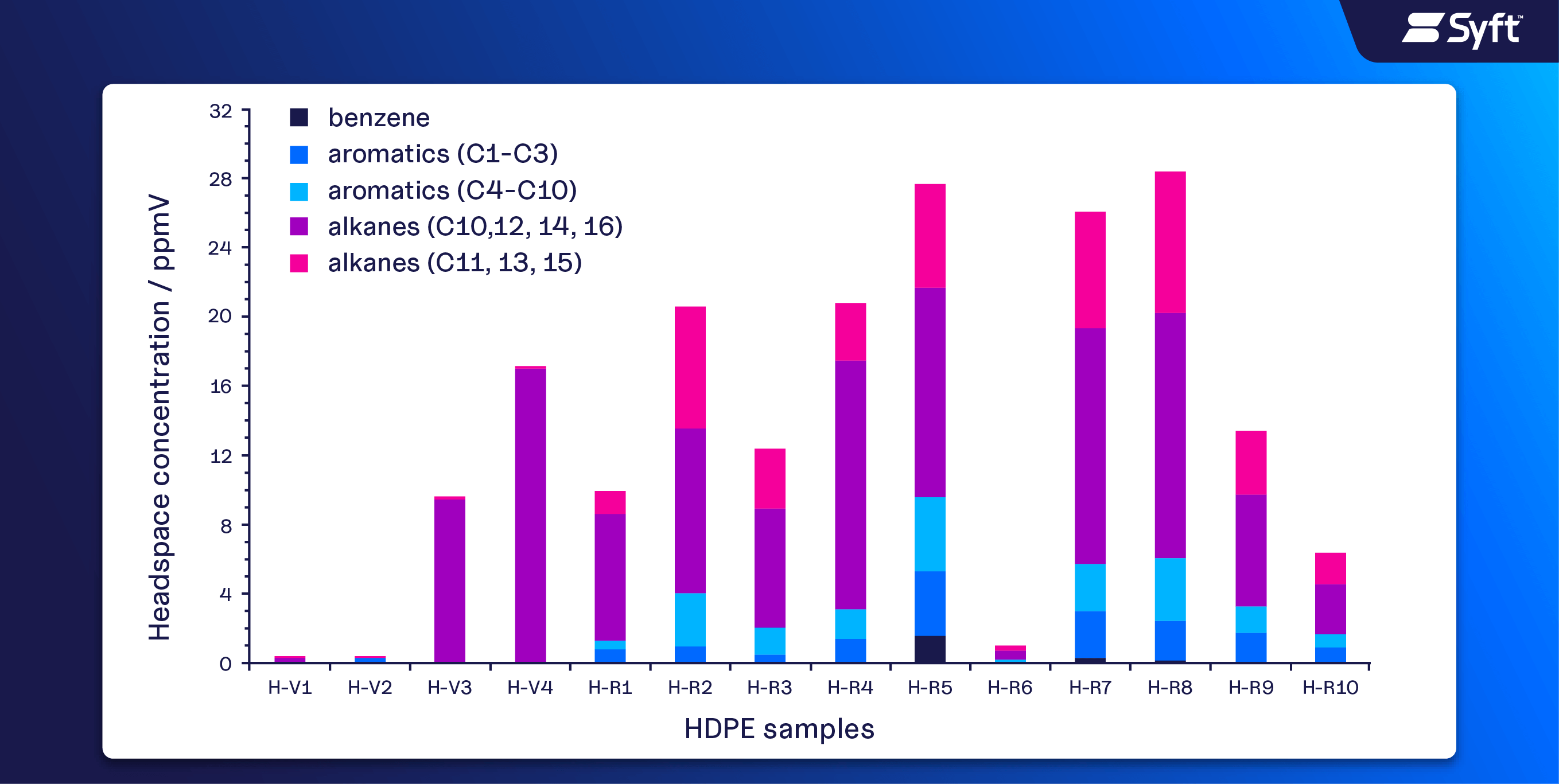

Polymers are synthesized by polymerization of low molecular weight organic compounds, and therefore monomer residues and other volatile by-products can be trapped in the polymeric material. Recycled polymers may contain additional volatile impurities that have migrated into the material during prior use and/ or that were generated through the recycling process. Determination of the identities and levels of volatile impurities is important for manufacturers planning to utilize recycled polymeric materials in packaging materials – whether of pharmaceutical products, foods, or personal care products (PCPs) – since they can migrate through the polymer into the product.