Introduction

Besides its use in analytical GC, HPLC and CE, the Clarity chromatography software is well suited also for control of preparative chromatography systems. Using the FCGP (General Purpose Fraction Collector) control module, many different fraction collectors could be controlled by the simple Next and Collect/Waste commands generated by the module and transferred to the devices either through the digital Outputs/Inputs or by suitable communication line (RS232, LAN, GSIOC). Not only dedicated fraction collectors, but also multi-position valves could be controlled. The fraction collection parameters (including time windows and signal level or slope triggered collection) are defined within the Clarity FC-GP method setup.

Two examples of automated systems used for isolation and purification of antibodies, based on common instrumentation and controlled by Clarity chromatography software are presented.

Automated Immunoaffinity Chromatography

This instrument setup is designed to isolate specific antibodies from clarified serum. The serum is obtained from an animal immunized with the antigen which we want to generate antibodies against. The media in the column has the same or a similar antigen covalently bound to it, in order to capture antibodies which are specific to that antigen.

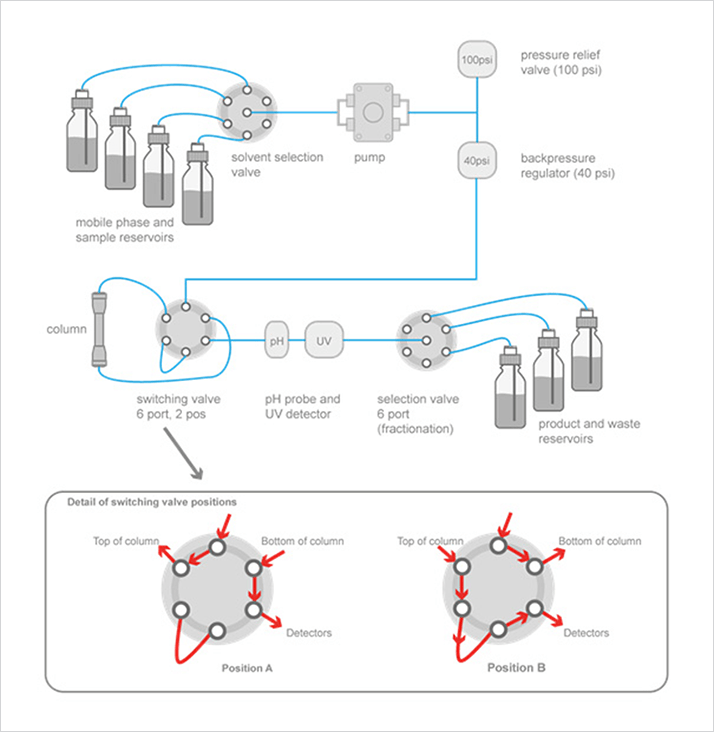

Figure 1: Diagram of the immunoaffinity separation system.

Figure 1: Diagram of the immunoaffinity separation system.The instrument is configured around our existing lab infrastructure (benches, racks, shelves, rods for mounting columns, etc.). A 6 position selector valve allows selection of serum, a wash buffer, an elution buffer, or a column cleaning buffer. The unused positions are plugged so that they can be selected to put the instrument into a standby state which prevents any siphoning of the mobile phases due to gravity. The output of the selector valve leads to the pump. Immediately after the pump is a backpressure regulator to ensure proper seating of the check valves and a second one, serving as a pressure relief valve, as the pump does not feature pressure monitoring.The tubing is then plumbed into a 6 port, 2 position valve, used to allow the direction of flow through the column to be reversed (see plumbing diagram). This allows strongly retained antibodies at the top of the column to be eluted quickly, with minimal exposure to the harsh elution buffer. After flowing through the column, the mobile phase returns to the valve and is directed through pH and UV detectors to a second 6 position selector valve, where the output can be directed to reservoirs for waste, eluted material, or material to be reloaded for further processing.