Introduction

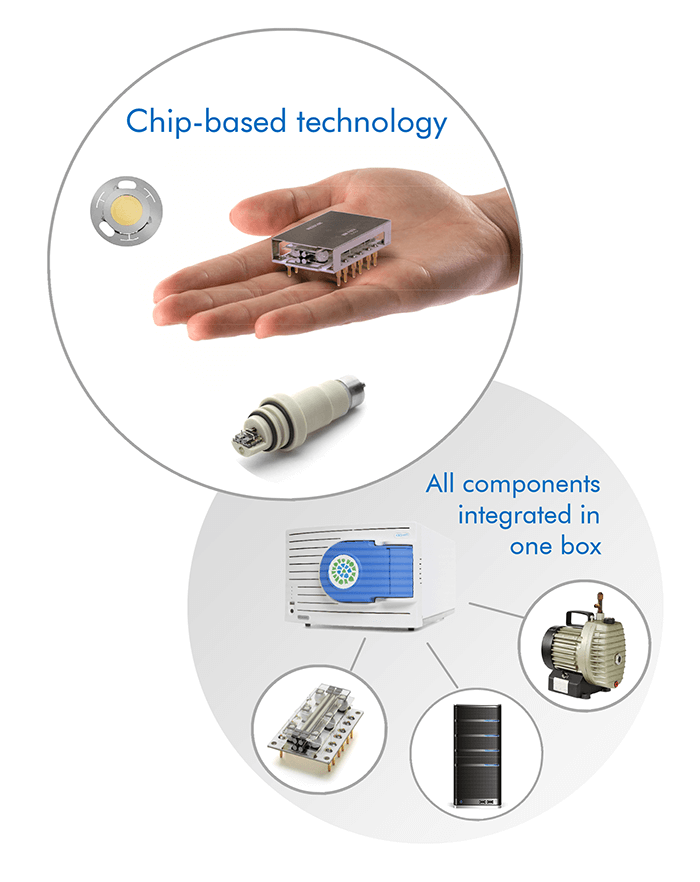

The Microsaic 4000 MiD® is a miniaturised single quadrupole mass detector designed for non-MS specialist users. The system retains the performance of conventional MS systems but is substantially smaller, less complex to operate and maintain with significantly reduced cost of ownership. The 4000 MiD® is designed with the vacuum system, electronics and computer all integrated in one unit ensuring the instrument can be installed in places where no other MS can be easily deployed (Figure 1). The Microsaic MiDas™ is a compact interface module that enables simple deployment of mass detection in a large variety of on-line, at-line and off-line applications. In particular, automated dilution is provided by the MiDas™ allowing MS analysis with minimal sample handling.

Microsaic Systems‘ application portfolio ranges from traditional LC-MS analysis to previously unserved markets that will benefit from deployable mass detection at the point-of-need. In this application note the versatility of Microsaic Systems’ application range is detailed along with the benefits of enhanced process productivity and profitability by integrating simple-to-use mass detection.

Figure 1. Microsaic 4000 MiD® utilises chip-based components.

Figure 1. Microsaic 4000 MiD® utilises chip-based components.Mass directed purification

Purification techniques, such as preparative and flash chromatography, have become a major part in the production of speciality chemicals and compound synthesis. Integrating simple-to-use mass detection in a traditional purification workflow overcomes many of the limitations of using optical detection alone. In the traditional workflow, fraction collection is typically monitored by ultraviolet/visible light (UV/VIS) detection. However, this technique is limited due to uncertainty over the composition of the collected fraction and leads to offline MS analysis carried out by specialised facilities to precisely identify the fraction composition. Fraction collection with online mass detection eliminates the additional time and cost required for off-line MS analysis. Process improvements with cost and time saving have been successfully proven by Microsaic Systems and demonstrated for the purification of peptides and small molecules (1).

Direct analysis

Direct injection MS analysis provides immediate mass identification and confirmation. The technique features automated on-line dilution with minimal sample preparation. Direct injection MS analysis finds applicability in the pharma sector as a means of rapidly screening samples and in academia as a teaching aid. Detection of counterfeit and adulterated alcoholic drinks by direct injection MS analysis has been reported by Microsaic Systems (2). Furthermore, whisky fingerprint analysis was carried out to demonstrate the ability to distinguish difference in brands and blends of whiskies.