Abstract

Total petroleum hydrocarbons (TPH) is a term used to describe a large family of several hundred chemical compounds that originally come from crude oil. The typical range from C5 – C40 consist of fractions and classes. The fractions range from petrol, through kerosene, diesel to oils, jet fuel and crude. The main classes of compounds present are saturated and unsaturated aliphatics and aromatics containing carbon and hydrogen. However there are lower concentrations of other classes containing oxygen such as FAMES (fatty acid methyl esters) from biofuels. From an environmental perspective not only total petroleum measurement is a requirement, but the compound classes and sometimes the individual components need reporting. This is due to the toxicity differences between the classes and individual compounds. In addition it is also very useful to know what fraction of petroleum is present, in the case of land contamination and how long it has been present.

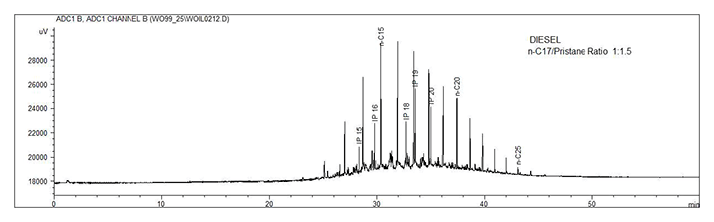

Typical Diesel Chromatogram

The current methodology to analyse for waters and soils for TPH involves extraction processes such as solvent/ Soxhlet or microwave digestion with various clean up steps possible, such as SPE. Subsequent analysis is by GC/FID with headspace, GC/FID, GC/MS or even GC/MS/ MS to analyse individual PAH’s. Then a manual assessment of the chromatograms is performed or an Excel macro used to distinguish between petrol, kerosene and differences between weathered or biodegraded products such as diesel. The whole process is a time consuming exercise with numerous sources of errors.

Introduction

JSB’s challenge was to minimise the sample clean up and provide more accurate and reliable TPH results. The five critical challenging areas were:

- Reduce sample preparation steps

- Minimise the number of methods for TPH analysis

- Visually display and report more accurate TPH data

- Visually display and report of banding, fractions, classes of compounds and individual compounds

- UKAS & MCERTS Accreditation

Instrumentation & Software

JSB’s customised gas chromatograph (based on Agilent 7890) fitted with 7693A auto sampler, split/splitless injector and Flame Ionisation Detector (FID). An Agilent Flow Modulator was used to control the instrumentation and GC image software to analyse and display the 2D images and data.