A vast number of chemical species are being used as polymer additives. These additives can become a major challenge in the quality control process. A singlestep pyrolysis GC/MS analysis often produces cluttered chromatograms without adequate separation between residual solvents, pyrolysis fragments, contaminants, and additives. Evolved Gas Analysis (EGA) in conjunction with multi-step pyrolysis can address this challenge. EGA provides thermal information which can be used to select appropriate multi-step temperatures. Each thermally sliced chromatogram will provide ample separation to yield well-resolved information.

A transparency sheet, 100µg, was added to a Drop-In-Sample Chamber (DISC) tube and analyzed with a CDS 6150 Pyroprobe connected to a GC/ MS containing a fused silica column. The sheet underwent EGA at 50°C per minute from 50°C to 800°C, sending vapors directly to the MS detector. This temperature ramp up rate is 2.5 times faster than traditional thermal gravimetric analysis (TGA).

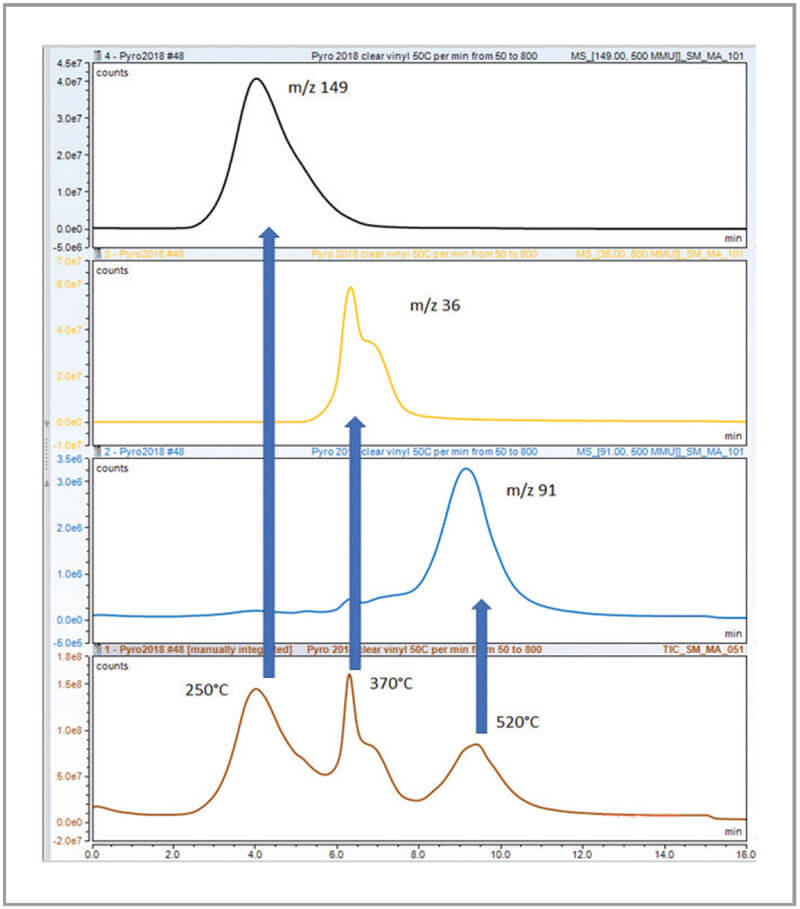

Figure 1, which displays the EGA from the transparency sheet, including a Total Ion Chromatogram (TIC), and Extracted Ion Chromatograms (EIC) has 3 defined regions of thermal outgassing. These peak regions occur at 250°C, 350°C, and 500°C. The first region is contributed by semi-volatiles (m/z=149) from phthalate plasticizers desorbed from the vinyl. The second and third regions are from material decomposition. The second region has an abundance of m/z=36 with a top match for hydrogen chloride. This represents the first step of polyvinyl chloride pyrolysis, removal of the chlorine side group. The last region has multiple masses associated with it; m/z=91, 106, and 115 indicate aromatics, and represent the stabilization of the remaining polymer chain.

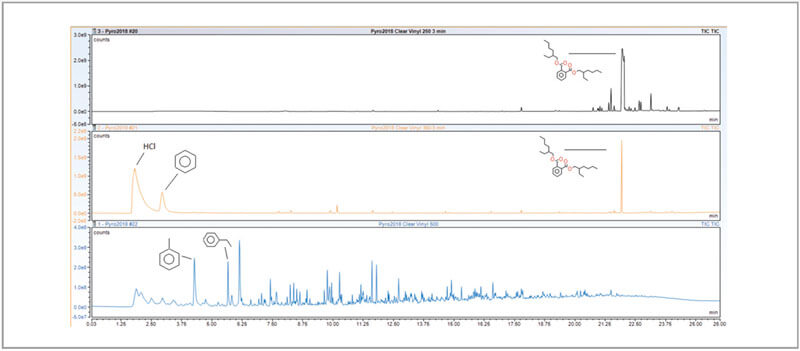

After obtaining the EGA information, 250°C, 350°C, and 500°C were chosen to separate semi-volatiles and polymeric components for GC-MS analysis. Dioctyl phthalate (Figure 2) was identified in the 250°C thermal slice. At 400°C, dioctyl phthalate is still extracting as the vinyl breaks down, releasing hydrogen chloride. At 500°C, the remaining portion of the vinyl are stabilized to aromatics.

Evolved Gas Analysis (EGA) in conjunction with multi-step pyrolysis can be used to effectively determine multi-step pyrolysis parameters, simplifying chromatography results of complex polymeric matrices.

Experimental Setup

Pyroprobe

Setpoints:

Initial: 50°C

Final: 800°C

Ramp Rate: 50°C per minute

DISC Interface: 300°C

Transfer Line: 300°C

Valve Oven: 300°C

GC-MS

Column: fused silica (1m x 0.10mm)

Carrier: Helium 1.25mL/min, 75:1 split

Oven: isothermal 300°C

Ion Source: 230°C

Mass Range: 35-600amu

Contact name: Carol Byrd

Contact Phone Number: 610.932.3636