Introduction

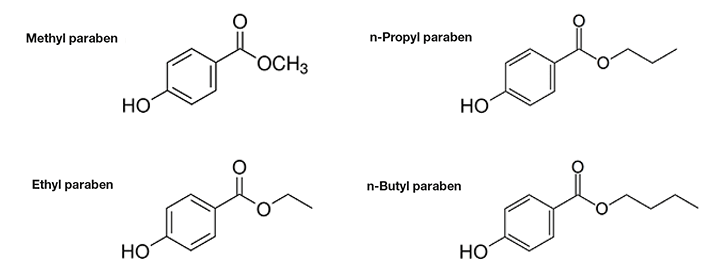

Parabens (esters of para-hydroxy benzoic acid) are widely used as food additives and synthetic preservatives in cosmetics and personal care products as well as in pharmaceutical formulations. Common types include methyl paraben, ethyl paraben, n-propyl paraben, and n-butyl paraben (Figure 1). Parabens are also used in combination with other preservatives to safeguard against an extensive range of microorganisms. It has been disputed that parabens can also be linked to breast cancer and other reproductive issues which have led to an onset of studies to determine the role that parabens play in diseases. It is therefore of the utmost importance to have a quantitative method that can accurately monitor paraben levels in food and other personal care products. In this technical note we describe a simple extraction procedure to quantitate four of the most commonly used parabens from baby wash using Novum Simplified Liquid Extraction (SLE) products in conjunction with a Kinetex® EVO C18 5 μm core-shell HPLC column.

Figure 1. Analyte structures

Figure 1. Analyte structuresExperimental Conditions

Sample Preparation

Novum SLE 12 cc Tube, part no. 8B-S138-KDG

Pretreatment

- Add 1.25 mL acetone and 0.6 mL 1 % NaCl solution to 0.5 ± 0.05 g of a commercial baby wash/shampoo which has been spiked to contain 100 μg/g parabens

- Gently mix for 30 seconds, avoid excessive foaming/emulsions

- Wait 30 seconds until the emulsion dissipates

- Centrifuge for 10 minutes at 3000 rpm

- Collect the supernatant and proceed to SLE procedure (below)

SLE Procedure

Sample Loading

- Load the sample from pretreatment step onto the Novum SLE sorbent and apply a short and gentle pulse of vacuum (~ 5” of Hg for 5-10 seconds or until the sample has completely entered the sorbent)

- Wait for 5 minutes

Elution

- Dispense 10 mL of ethyl acetate onto the SLE media and allow the solvent to elute by gravity for 10 minutes and collect the eluent

- Apply vacuum at 5-10” of Hg to complete the extraction

NOTE: Prolonged application of vacuum will result in elution of baby wash out of the SLE media and into the final extracted solvent

Reconstitute

- Evaporate the final extract to complete dryness under slow stream of N2 at 45 °C

- Reconstitute the dry residue in 0.5 mL of methanol

- Centrifuge for 10 minutes at 6000 rpm

- Collect supernatant and inject onto the HPLC