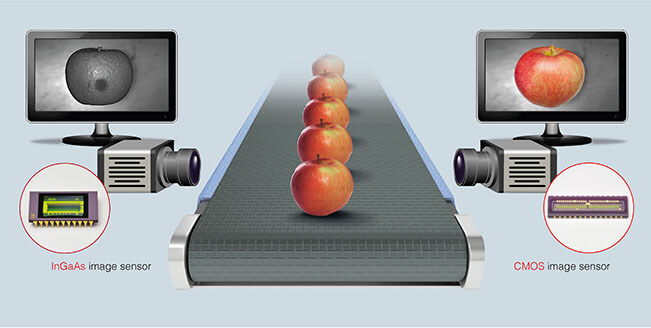

These companies face significant challenges such as agricultural products contaminated with stones or other debris, broken or unsealed packages, mislabeled products, and spoiled produce. Fortunately, many solutions that address this are available using today’s technologies including SWIR, InGaAs and CCD/CMOS.

Challenges in the quality and safety of food inspection

Integrated in devices designed for improving food inspection, sorting, safety and quality are found cameras and sensors. These systems can identify issues in food products and packaging before they are shipped out. Vision inspection can prevent unsafe, low-quality food from reaching shelves and saving businesses costs on returned defective packages.

One example is seen in coffee production, which is enhanced through machine vision. Coffee beans are placed on the tarp on the ground for drying, then raked up and put in a hopper. During this raking process, rocks or gravel can easily get mixed in with the coffee beans. These stones need to be sorted out before the beans are packaged. If stones go unnoticed and are packaged with the coffee beans, they can present sanitary issues and can cause coffee grinders to break. Machine vision can be used to distinguish between items of similar shape and size.