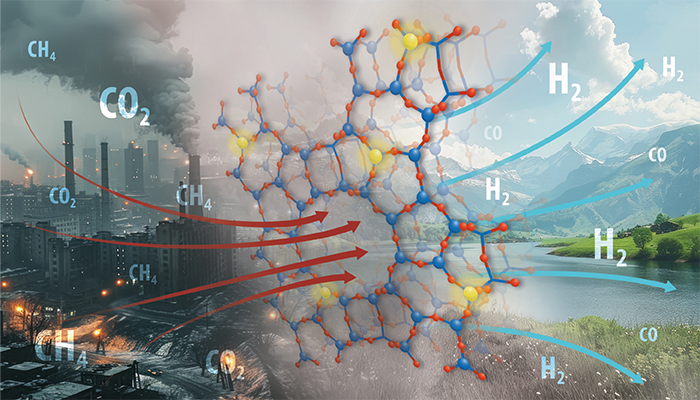

A team from Oak Ridge National Laboratory have designed a new method to enhance the stability of nickel catalysts for dry reforming of methane (DRM): a promising route for converting two prevalent greenhouse gases, namely methane and carbon dioxide, into a valuable industrial feedstock, known as “synthesis gas” (syngas).

Syngas, a mixture of hydrogen and carbon monoxide, is used to produce chemicals of mass consumption on a global scale, such as hydrocarbon fuels like diesel, as well as industrial chemicals such as ammonia. However, high temperatures are required to avoid carbon disposition, which rapidly deactivates the reaction’s catalysts. Ni-based catalysts are usually favored for their cost-effectiveness, but up to this point their tendency to sinter and form coke has limited their operational stability.

The researchers used X-ray absorption spectroscopy (XAS) and diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) to demonstrate that increased airflow during synthesis strengthens Ni–silica (Si) interactions, leading to more stable catalytic sites. Catalysts with dispersed Ni sites exhibited greater resistance to sintering and carbon deposition during extended DRM tests at moderate temperatures. The most stable catalyst maintained its structure and activity for over 60 hours, outperforming traditional Ni catalysts.

The global syngas market is expected to reach a value of $66.5 billion by 2027, due in part to the growing demand for renewable energy. In addition, ammonia, a product of syngas components, has a key role in the production of nitrogen-based fertilizers – which make up around 58 percent of total fertilizer consumption globally.

With a look towards the future, the authors believe that the principles of the method could be applied to increase catalytic stability in other favourable reactions used by industries. “We're looking for alternative ways to excite the reactant molecules to break thermodynamic constraints," revealed co-lead author Felipe Polo-Garzon in a recent press release.

“We are developing design principles to stabilize catalysts for a broad range of industrial processes. It requires a fundamental understanding of the implications of synthesis protocols. For industry, that's important because rather than presenting a dead-end road in which you try something, see how it performs, and then decide where to go from there, we're providing an avenue to move forward."

With an improved catalyst, ORNL chemists converted two greenhouse gases, methane (CH4) and carbon dioxide (CO2), to syngas, a valuable mix of hydrogen (H2) and carbon monoxide (CO). Credit: Philip Gray/ORNL, U.S. Dept. of Energy