The problem

I spent most of my PhD and postdoc years analyzing foods and petrochemical derivatives using various chromatographic techniques, starting with gas and liquid mobile phases, and graduating to CO2 supercritical fluid. The samples I work with are very complex, encompassing not only multiple components but also a huge variety of chemical classes and concentrations. Moreover, most require a sample preparation step before the chromatography separation. Consequently, a number of different analytical techniques and sample preparation steps are usually needed to obtain reliable results. The challenging nature of such analytical methods led me to ask, “Is it possible to combine sample prep and complex analysis in a single fully-automated system?”Background

Working in the laboratory of Luigi Mondello at the University of Messina, I have spent a great deal of time coupling different analytical techniques (liquid, gas, and supercritical fluid chromatography) to generate more powerful instruments. Under the supervision of Mondello and Peter Tranchida at the Separation Science Center in Messina, I later widened my focus to include both spectroscopy- and spectrometry-based detection methods. My introduction to the world of separation science was via standard gas chromatography, and later comprehensive two-dimensional gas chromatography (GC×GC), which showed me the incredible resolving power of hyphenated techniques. Later, my research focused on the analysis of volatile contaminants in foodstuffs that contained a large number of non-volatile components, such as vegetable oils, which are mainly composed of triglycerides. Here, a sample preparation step is mandatory for a reliable qualitative and quantitative analysis but is time consuming and carries a risk of sample loss or contamination. An on-line system coupling sample preparation and separation seemed an obvious solution. Normal-phase liquid chromatography can be used to retain the triglycerides, while non-polar solvents are well suited to gas chromatography, allowing the transfer of a purified fraction containing the volatile contaminants. Coupling the two techniques (LC-GC) creates a very powerful separation tool with enhanced selectivity and sensitivity. However, in the Mondello lab we always want to push things further. So we designed a prototype of an on-line tool coupling LC with GC×GC, hyphenated with a very fast triple quadrupole mass spectrometer. LC is useful for sample preparation/pre-separation, GC×GC brings a very high separation power and sensitivity, and the detector offers both targeted and untargeted applications. Such a system represents the first five-dimensional analytical tool; three chromatographic and two mass spectrometry dimensions are combined.The solution

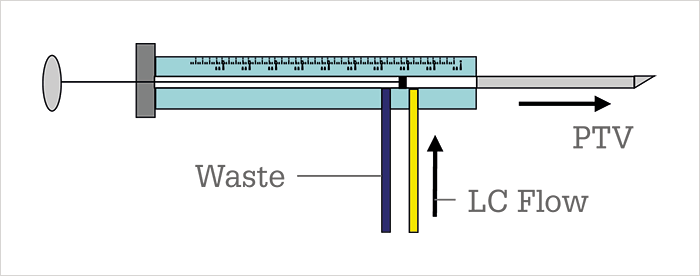

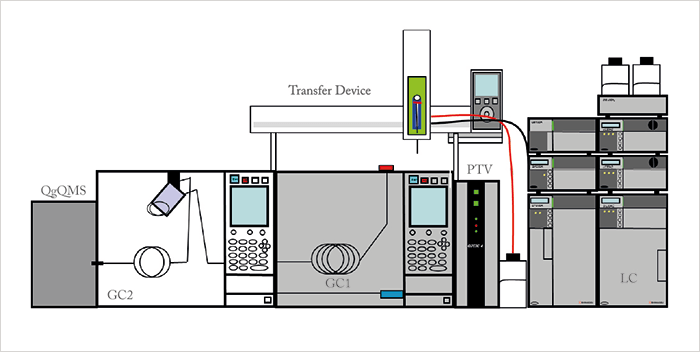

After a weekend spent connecting parts of instruments from the lab (with help from service engineer Alessandro Visco), we were able to perform the first run. The first part of the instrument is a conventional LC system with two dual-plunger parallel-flow pumps, making it possible to perform gradient analysis for the most challenging samples. The PDA detector was connected via PEEK tubing to a dedicated dual side-port syringe, installed in an auto injector, and was employed as transfer device (see Figure 1). Chromatography fraction transfer was achieved, in the stop-flow mode, through a modified 25 μL syringe. Briefly, the lower part of the syringe has two transfer lines – one to the LC detector exit and one to waste. A Teflon plug is located at the end of the syringe plunger; the latter is characterized by a lower outer diameter with respect to the barrel ID, enabling mobile-phase flow inside the syringe. In waste mode, the syringe plug is located below both lines and the effluent is directed to waste. In the transfer position, the syringe plug is located between the lines and the effluent flows to the GC. It is worth noting that potential band broadening during the stop-flow mode could be observed through continuous PDA monitoring. To handle very large amounts of solvent from the LC system, a programmed temperature vaporizing injector (PTV) was used.

The GC×GC side consists of two gas chromatographs and a cryogenic modulator. The presence of two independent gas chromatographs allows a very high analytical flexibility, with the opportunity to perform two different GC oven temperature programs. Finally, we decided to use a very high acquisition rate triple quadrupole MS detector, allowing both targeted and untargeted analysis. The mass spectrometric system generated a more-than-sufficient number of data points/peaks for both identification and quantification purposes (Figure 2 shows the configuration of the final instrument).

Having finalized the hardware configuration, we then focused our attention on software development. I spent a lot of time with Shimadzu engineers Tomohiro Kawase and Jun Nagata, and visited the beautiful city of Kyoto, Japan, to help develop intuitive software to control each part of the instrument. The resulting software allows the user to perform single or multiple LC cuts – sequential or not – with repetitive or different transfer times, and use different PTV and GC methods, optimized according to the transferred fraction. Moreover, to make GC×GC analysis easier, we developed software to calculate the average linear velocity inside the first and second dimension and the delay loop. The LC-GC×GC/QqQ MS system represents a unified and flexible instrument that can perform one-dimensional, heart-cutting and comprehensive two-dimensional chromatography analyses: LC/PDA, LC-GC/QqQ MS, LC×GC/QqQ MS, LC-GC×GC/QqQ MS, LC×GC×GC/QqQ MS, GC×GC/QqQ MS, and GC/QqQ MS. The system can be used in any of the seven configurations, depending on the sample complexity, simply through selection of the appropriate software settings.

I’ve condensed the story here but of course in reality there were many more twists and turns (one reason that the project was so fun!), with both hardware and software presenting significant challenges. Communication between modules had to be carefully considered – a single start signal for seven different devices (LC, transfer device, PTV injector, two GCs, modulator, and MS) means a lot of cables! Similarly, the main software challenge was compatibility between the modules. A single OS is not enough for their coexistence, so we had to install a virtual machine to overcome the various incompatibilities.