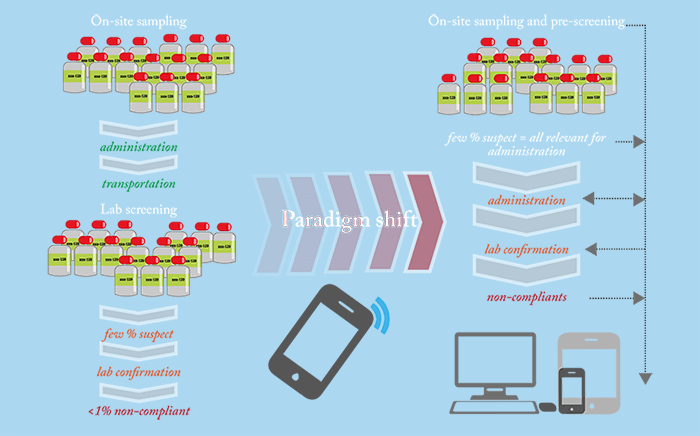

In the field of analytical science and technology, a two-sided trend is becoming apparent. In the future, there will be an increase in on-site testing at the point of care in hospitals and GP offices, but also in the field, at farms, in retail spaces – and even at home. And that means a great deal of lab work will move to the end user. At the same time, there is also a trend towards very high-end instrumentation and orthogonal techniques that can measure both biological and physical chemical parameters in a method. I saw the same trend in food analysis – and that’s why two years ago, I applied for a European PhD training network project called FoodSmartphone, which ultimately aims to bring the tools of the routine food analysis lab to end users. I see three different and highly complementary ways of achieving that goal – but all three have different starting points and development times.