Analyzing moisture content doesn’t sound exciting – but it is critical. After all, moisture content is a defining component of many materials, products, and foods. And that’s why it is subject to rigorous quality control in both production and laboratory facilities. For food producers and packers, pharmaceutical manufacturers, and biological researchers amongst many other industries, controlling the moisture content at all stages of processing greatly influences the physical properties and quality of the final product. Let’s take a deeper dive into the water in our food – and the simple but crucial role of the Whatman moisture testing papers.

Moisture is simply water that exists diffused in a substance, usually in relatively small amounts. Nearly all materials will contain moisture, which contributes to its overall mass. Water held within the structure of a substance is defined as its moisture content. However, this content is not static and depends upon the amount of moisture the material is capable of absorbing (hygroscopic action) relative to ambient conditions (temperature and humidity). This dynamic process is evidenced as weight changes in the material. Understanding moisture content and controlling it is fundamental to certain processes, such as food dehydration, where stripping food of water has a clear and measurable impact on weight.

However, it is not just weight that is important. Weight, thermal expansion, and electrical conductivity are all examples of properties that can be altered by variations in moisture content. Moisture provides structural components too and, in the food industry, moisture content is a vital component for estimating shelf life.

Microbial activity within food is promoted when there is sufficient moisture content; the more moisture within a foodstuff, the faster it is likely to degrade. This reality is further complicated by the practice of adding further water to food, which is especially common in frozen goods where, for instance, poultry is injected with water, salts, flavorings, and hydrolyzed protein, which further retains moisture. Regulatory policies provide legal limits regarding the amount of water either introduced into our food or present during the processing. For instance, during the production process of cheddar cheese, moisture levels must be below 40 percent. Another example: the EC limit for water added to a frozen, whole chicken is 7 percent.

Of course, control of moisture content also has an economic impact on producing and packaging food as well as a measure of product quality, standardization, and consistency. As such, effective moisture testing is a vital part of moisture control throughout the whole processing chain.

In direct methods of measurement, water is removed through physical techniques and the amount of water is measured by weighing (either the water extracted or the change in the product) or by titration (Karl Fischer volumetric titration). Both of these methods produce reliable results but they are time consuming and labor-intensive. Depending on the product in question, they also rely upon different methods to extract the water, including air or vacuum oven-drying, freeze drying, chemical desiccation, and sometimes gas chromatography. Moreover, each drying method requires different equipment and a different type of moisture analysis.

Although reliable, such direct methods are not practical in certain settings; here, indirect methods must be adopted. Indirect methods measure the change in some property of the food that varies as moisture content changes. Such methods include refractometry, infra-red (IR) absorption, near field IR absorption, microwave adsorption, dielectric capacitance, conductivity, and ultrasonic absorption. As such methods do not remove water from the food, they must be pre-calibrated using direct methodology, which means their accuracy is dependent on the accuracy of the initial process. Indirect methods are generally considered less reliable than direct methods; however, they are fast and often require little sample preparation.

Unfortunately, both direct and indirect methods can be inconsistent. Any methodology that relies upon heating can potentially cause samples to lose organic volatiles as well as water, or cause sample decomposition. And this is particularly true in foods with high sugar content. Drying food also raises other challenges; choice of drying times and heat cycles becomes critical, which has led to the plethora of drying methodologies.

In direct measurement, moisture analyzers are now commonly available as a single instrument – essentially, devices that combine precise weighing and heating controls. One common version, which relies on a halogen heating unit, meets the needs of quality control and production in food, pharmaceutical, chemical, and other industries by offering accurate results in a closed system that is relatively easy to operate, which crucially promotes reproducibility.

But in the food industry samples can be highly variable, so must always be an important consideration when it comes to methodology. Some foodstuffs may require slow heating whereas others can withstand a quick burst of high temperature to drive out the water content. Stepwise drying is also a common choice, and the halogen system can accommodate these approaches. Unfortunately, one limitation is that the measurement process generates so much heat that they cook the sample or even burn it, both of which can confound a true reading of moisture content. Notably, water can become trapped in residue that adheres to the porous support surface. Moreover, spoilage tends to require a more stringent cleaning protocol for the surface supporting the sample, which limits the throughput rate of the instrument.

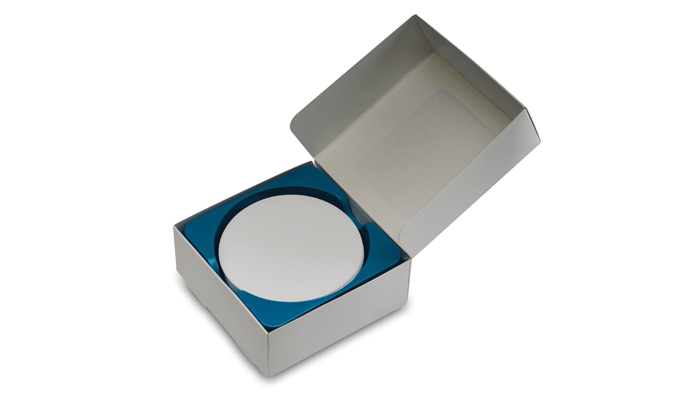

The practical challenges of holding food intact while it is being heated and while capturing moisture loss are steep, and this is where moisture testing papers, such as the Whatman product, can make a significant difference. Moisture test papers form a physical barrier between the sample and the instrument bed – a simple, yet elegant solution that supports sample transfer and containment throughout the process. Crucially, the Whatman moisture testing paper does not affect the moisture reading; it is made of non-hygroscopic materials, so it does not sequester water from the sample through contact nor does it introduce non-sample excess moisture that is driven off from the paper in the heating process. The paper is inert and thermally stable, and does not contribute to gravimetric loss during the drying cycle. And it is also strong, so it will not deteriorate through contact with damp or gelatinous food samples.

Knowing the major impact that moisture content can have on the quality and safety of your final product, you will be keen to eliminate any source of error or variation in your chosen analytical system. Whatman moisture papers are specially designed with a simple yet specific task in mind – because we want you to be fully confident that your measurement is as accurate as it can be.