Meet the Experts

Adam Woolley

“For some time, research in the Woolley laboratory has focused on the interface between biomolecules and miniaturization. Current efforts are directed toward making microfluidic devices that can carry out biomedical assays and using bottom-up self-assembly to nanofabricate electrical structures. Over the past decade, my group has focused increasingly on the development and application of 3D printing in the creation of microfluidic devices. In collaboration with Prof. Gregory Nordin in BYU’s Department of Electrical and Computer Engineering we have developed 3D printers that can readily form truly microfluidic structures, including microchannels, pumps, valves, and mixing chambers – all of which have equivalent functionality to devices made from materials now in use, such as PDMS.

“Two recent publications on our work with 3D printed microfluidics were directed at creating integrated devices for the electrophoretic analysis of biomarkers related to preterm birth risk (1) and the generation and use of concentration gradients in studying chemotaxis (2). We are currently focusing on increasingly integrated microfluidic systems that carry out sample preparation processes in conjunction with analysis.”

Adam T. Woolley is Professor at Brigham Young University, Utah, USA

Rosanne Guijt

“The focus of my group is the development of new technologies for early detection of threats and disease. So at the core, it is applied/bioanalytical, but the demand for early, point-of-need detection drives the motivation to develop and adopt new technologies. For a long time, my research has been driven by the ambition for functional integration, because I believe that functional integration is the stepping stone towards realizing chemical and biochemical monitoring systems capable of picking up threats early and on-site.

“I was recently fortunate to obtain an ultra-high resolution 3D printer, so I will be deploying that for challenges that cannot be addressed with other printers. At the same time, we will also continue to observe the consumer segment of the 3D printer market, as this provides entry-level access to researchers. Additionally, my passion for functional integration will continue to seek new ways of combining and integrating materials to enable a growing share of the analytical workflow to be integrated on a single device.”

Rosanne Guijt is Professor of Smart Sensors at Deakin University, Victoria, Australia

James Grinias

“Our lab broadly focuses on the development of liquid chromatography (LC) methodology, column technology, and instrumentation. In the area of miniaturization, we have been working with a compact, portable LC instrument in collaboration with Axcend for the analysis of pharmaceutical compounds, clinical samples, and on-line monitoring of chemical reactions. We are also working on a separate platform designed to help scale down 2D-LC methods to capillary-scale flow rates.

“We have demonstrated many applications of small molecule separations using compact capillary LC instrumentation, but recently moved into the area of biopharmaceutical analysis. Results from the analysis of a therapeutic antibody were comparable to that obtained using benchtop instrumentation.

“We hope to expand on the recent biopharmaceutical analysis work by adding additional characterization techniques that rely upon a broader range of LC separation modes. We are also beginning to implement more sample preparation strategies into our workflows that are specifically designed to couple to compact capillary LC methods to enhance the analysis of clinically relevant samples in point-of-need settings.”

James Grinias is Professor in the Department of Chemistry & Biochemistry at Rowan University, New Jersey, USA

What is the current state of miniaturized separation technology?

James Grinias: On the LC side, there are multiple groups working on portable instruments around the world. Many of these systems are also being commercialized, which broadens their accessibility to the wider scientific community. I think one of the biggest milestones in this area has been the emerging adoption of these instruments by major pharmaceutical companies for various analytical needs.

In the broad context of capillary LC, I think there is a major case to be made for the reduced environmental impact of the technique relative to traditional analytical-scale LC. There are several routine methods out there designed for the analysis of relatively simple mixtures that are long (tens of minutes) and run at high flow rates (1-2 mL/min). Capillary LC has advanced to a point where the volume of solvent waste generated from such analyses can easily be reduced by three to four orders of magnitude while delivering comparable results.

However, capillary LC remains a very small part of the broader field because of hesitancy to adopt such methods. Some of this is due to perceived notions of column and instrument robustness at these scales, while part of the motivation is simply a desire to not change methods that are working. As more companies move forward with plans to meet reduced carbon emission and waste generation goals, a shift to capillary LC will be a key tool for chemical analysts to adopt.

Rosanne Guijt: I would also like to highlight the healthcare sector, where there is a financial impetus for miniaturization – with demands for manufacturing (encapsulation of mRNA vaccines), as well as point-of-care diagnostics driving new developments in the field. James is also right about the environmental angle – people are concerned with the sustainability of the materials and reagents they’re using, and I anticipate that this driver will gain momentum into the future.

In parallel, with the phasing out of animal models for drug testing, organ-on-a-chip devices have rapidly expanded. With geometries and conditions varying for different cell types (organoids), I anticipate parallel development in 3D printing for cell culture for medical research and drug screening.

Adam Woolley: It has been more than three decades since initial studies on microchip electrophoresis were published, and hype for microfluidics continues to ebb and flow. Initially, microfluidic aspects of an assay were highlighted directly as an end goal, for example, in Caliper’s technology in the late 1990s. Now, miniaturized assays use micromachining or microfluidics in their operation as a means to achieve improved chemical analysis, for instance, the micro-chip based chromatography columns from PharmaFluidics (now Thermo Fisher Scientific).

Given the maturity of the miniaturized chemical analysis field, one might assume that innovative work is no longer occurring. On the contrary, novel advances continue in miniaturized analysis, particularly for droplet microfluidics in cell analysis, omics, 3D printing as a tool to create miniaturized systems, and a variety of electrochemical sensing platforms. Many of the drivers of miniaturization remain unchanged from the early days: automation, scalable/low-cost/disposable devices, and reduced chemical consumption. Furthermore, the ability to achieve novel assay designs and outcomes through microfabrication continues to motivate analytical scientists.

But the two key questions remaining to be addressed with miniaturization are: i) how can analytical scientists continue to innovate in a maturing field? and ii) how can multiple “breakthrough applications” be brought to fruition?

What are some of the most promising developments in 3D printing for analytical applications?

Adam Woolley: One key current direction in 3D printing involves process-specific customization. For example, the creation of custom materials for 3D printing for solid-phase extraction (3) or the development of non-standard 3D printing processes to incorporate new components into devices (4). These trends illustrate the need for 3D printing practitioners to be able to access the inner workings of the process to achieve novel results.

Another recent focus in 3D printing for chemical analysis miniaturization entails effectively using all three spatial dimensions within devices (5). Key advantages of this approach include significant miniaturization of devices, dramatically scaling up microdevice fabrication rates, and creating novel architectures and analysis modalities in 3D prints. Importantly, greater utilization of all three dimensions in microfluidic systems also opens the door to using the same 3D printing platform for both prototyping and production.

A final area where important advances are occurring is on the commercialization front. I will avoid specifics because I own shares in a company, but I see promising advances in technology with multiple startups, as well as established 3D printing companies that are now focusing greater attention on the microfluidics and miniaturized chemical analysis market. Broader commercialization will be essential for 3D printing miniaturization to truly make a difference in analytical chemistry.

Rosanne Guijt: With my passion for functional integration, I am pleased to see multi-material options growing across different printer types – both in the research and in the commercial space. Because material integration can be done without compromising resolution, 3D printing will become a viable prototyping/small-scale manufacturing approach for lab-on-a-chip devices. It will be really exciting to watch this space over the coming five years. However, because microfluidics is a specialist area within the 3D-printing space, many advances in materials are not yet applicable to printing fine channels. It is important not to extrapolate findings on a mm scale to potential at a µm scale, but experimentally validate suitability.

From a commercial perspective, microfluidics is increasingly used at the heart of pharmaceutical manufacturing and diagnostics – so there’s a bandwagon 3D printing can jump onto there. There’s also a drive to mitigate climate change – the EU in particular is a driving force – and materials and devices with the potential to aid that mission are anticipated to grow. In particular, there is great potential for the use of advanced nanocomposite materials to replace current energy-intensive chemical processing.

Moreover, with 3D printing also having penetrated high schools, new people entering the field from various disciplines will already bring expertise in 3D printing with them as part of their education, which will facilitate adoption.

Having said that, training is still a big challenge! 3D printing is a combination of understanding the technology, the materials, the fluidics and the application; as a result, it relies on a cross-disciplinary skill set. This reliance is associated with a risk that if the depth in one or two of these aspects is lacking, elements may be overlooked. And that may lead to a loss of time reinventing the wheel or in the delivery of an inferior product. So communication and collaborative skills to work in a diverse team are at least as important as the technical aspects.

James Grinias: I continue to be excited about the prospects of 3D printing in separation science, especially in the area of sample preparation. People are combining novel geometric designs with advances in material science to come up with more effective analyte extraction devices that can be manufactured by anyone with a low-cost printer. This area is sure to continue emerging in coming years.

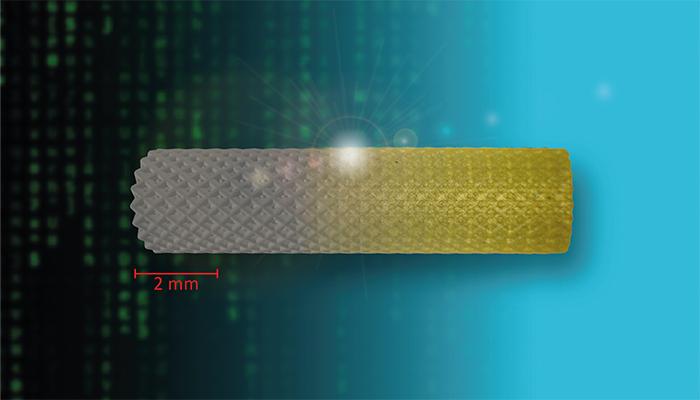

We are still in the early stages of a “fully printed” LC column. A number of advances have been made for preparative-scale separations, and I think there is a wide-open area to explore as we move into more traditional analytical separations. Many experts in the field have demonstrated that printer resolution is a current limitation, with the platforms that can effectively “print” stationary phases with sufficient resolution still being far too slow for routine use. The growing adoption of pillar array columns has shown that there is an appetite for perfectly ordered columns for specific applications, and 3D printing will only expand what can be achieved in this area over the coming decades.

What does the future of miniaturized analysis look like?

Rosanne Guijt: I am convinced of the need for technology able to translate the full analytical workflow to a system that can be operated at a point-of-need setting – and preferably autonomously to provide the time-resolved data required for understanding where the disease or environmental hazard/chemical process sits relative to its life cycle.

Focusing on the devices made by 3D printing, I feel it currently fills a void demonstrating performance using a scalable manufacturing route, addressing a significant obstacle in the prototype-to-market translation. For product manufacturing,it may only be possible to deliver on projects where the 3D-channel geometry is quintessential and cannot be made for a similar cost using traditional approaches. On the horizon, sustainability of materials and resins may come into play, as well as a desire to decrease transport kilometers in the supply chain – 3D printing would be compatible with decentralized, demand-driven manufacturing. With the cost and throughput of 3D printing, however, in the near future applications will remain mainly in prototyping and small scale production, with the exception of boutique applications that cannot be realized using any other manufacturing approach.

I would welcome a move away from 2.5D to 3D thinking in the design phase and understand how and where the 3D geometry and design provides the opportunities. As a community, we have remained too traditional and not truly embraced the 3D build space. We must embrace what 3D printing has to offer in design – the lab-on-a-chip community has yet to do this, which is impeding progress.

James Grinias: I am hopeful that compact separations-based platforms will eventually play a role in routine clinical diagnostics. Most LC-based clinical assays rely upon third-party testing services conducted in off-site laboratories. As the performance of miniaturized LC systems continues to improve, I think that these tools can eventually be used to help deliver real-time results in clinical settings. The MasSpec Pen is already demonstrating what MS can do in surgery rooms and I think LC could play a comparable role for applications like routine drug testing.

Scaling up commercialization and broader adoption can be a “chicken-and-egg”-type problem. I am hopeful that members of the academic community can continue partnering with emerging companies to demonstrate the power of new, miniaturized technologies in various industries, which can eventually lead to wider use and overall commercial growth. Specifically for compact capillary LC systems, I think that a wider array of columns in the 0.1–0.3 mm diameter range could broaden the application space, as most column manufacturers typically stick with 2.1–4.6 mm diameter columns.

Adam Woolley: I am excited and optimistic for the future of miniaturization in chemical analysis. In conjunction with the longstanding emphasis on bioanalytics, I anticipate a strong push toward implementation of miniaturization technologies in omics, particularly in studying single cells. Environmental analysis is a field where miniaturization has untapped potential, particularly where “drone” technology and 3D printing customization can provide previously impossible remote access with customized analytical capabilities. Miniaturized chemical analysis tools are ripe for advancing food security, from pest sensing/abatement to water and fertilizer sensing and optimization.

Nonetheless, there are challenges to overcome for miniaturization to reach its full potential. The funding environment, particularly for academic research in the US and Europe, remains stubbornly tight, hindering the exploration and development of innovative miniaturization technologies. Furthermore, effectively bridging the divide from academic concept to commercial assay continues to be an issue in need of better solutions. Another key need is to decrease device costs, particularly for more complicated assay systems; this may require novel or improved materials and fabrication processes.

Finally, I conclude with opportunities for introspection for those in the field. Are there changes that can be made in the funding ecosystem to enhance innovation? How can the publishing world disincentivize the proliferation of “me too” microdevice assay publications? How can miniaturized chemical analysis practitioners shift focus from device operation innovation to application and problem-solving innovation? Is there more that can be done to foster the transition to commercialization? What are novel approaches to incentivize investment in the most promising technologies? How can we facilitate key conversations between academic, healthcare, government, and industrial stakeholders to advance solutions that analytical scientists can direct at the greatest problems our world faces today?

Working together to answer these questions will help miniaturized chemical analysis practitioners remain relevant for decades to come.

Headshots supplied by interviewees

Credits for the images used in the collage:

Image 1: Woman hand hold virtual business card, credit card or blank paper isolated on white background by Artem Furman sourced from shutterstock.com Image 2: Black 3d printer finishing printing a businessman in the black suit, isolated on the white background. Additive manufacturing. Creating products of plastics by Gearstd sourced from shutterstock.com Image 3: Lab on a chip microfluidics device by luchschenF sourced from shutterstock.com Image 4: Shot at the New Jersey Institute of Technology by Mathew Schwartz sourced from unsplash.com