Summary

This Application Note gives advice on which sorbent to use for pumped or diffusive tube monitoring of various vapour-phase organics, and suggests parameters for conditioning and storing packed tubes. See also Application Note 027 for more information.

Note that guidance given for sorbent selection for a given analyte or analytes will typically apply whether that sample tube is to be used in pumped or diffusive mode. (For further information on diffusive sampling, see Application Notes 001, 002 and 010).

Introduction

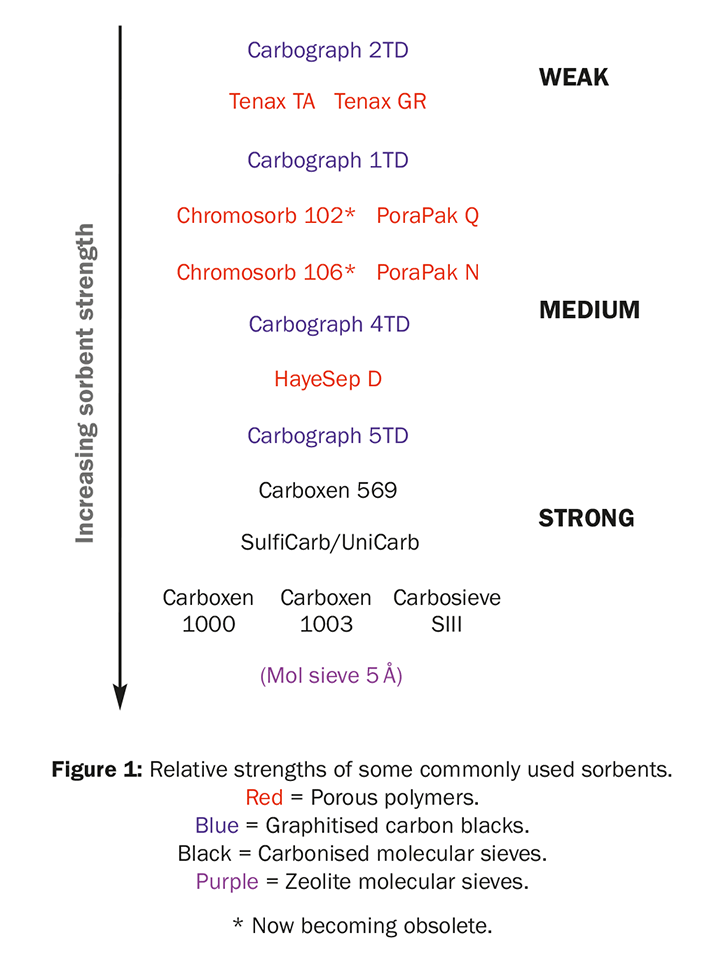

Selection of the correct sorbent or series of sorbents for sampling and release of the analytes of interest is one of the most important factors when developing a valid and robust thermal desorption method. Tube conditioning and capping are also critical issues. The choice of sorbent principally depends upon the volatility (specifically the vapour pressure) of the analyte concerned. In short, the sorbent or series of sorbents selected must quantitatively retain the compounds of interest from the volume of air/gas sampled, and must then release those compounds as efficiently as possible during thermal desorption. As vapour pressure data is not always readily available, a useful rule-of-thumb is to use the boiling point of the component as a guide to its volatility. In general – the more volatile the analyte to be trapped, the stronger the sorbent must be. See Figure 1 for an approximate guide to sorbent strength.

The following pages provide summary information on some of the most commonly used sorbents, in order of increasing strength. Note that sorbent tubes should typically be conditioned using higher temperatures and faster gas flows than those selected for analysis, provided the temperature limits of the materials are not exceeded.

Types of sorbents

Porous polymers Most porous polymer sorbents are inert, making them suitable for the analysis of labile and reactive compounds such as thiols, terpenes and CS gas. In addition, their hydrophobic nature allows them to be used for sampling in humid conditions. However, some porous polymer sorbents (i.e. Chromosorb, PoraPak and HayeSep) can exhibit high artefact levels and significant batch-to-batch variation. Aromatic hydrocarbons can also be generated over time, and for these reasons we recommend that these porous polymer sorbents are avoided for monitoring trace-level analytes. The Chromosorb Century series sorbents have also recently been obsoleted by their manufacturer, and are increasingly difficult to obtain.