While the current percentage of biopharmaceutical drugs approved and used as human medicine is small compared with small molecule drugs, EvaluatePharma® finds that “the percentage of sales from biotechnology products (bioengineered vaccines & biologics), within the world's top 100, is set to increase from 39% in 2012 to 51% in 2018. In the broader market, sales from biotechnology products are expected to account for 25% of the world pharmaceutical market by 2018, versus the current share of 21% in 2012”.1 Growing interest in biopharmaceuticals has led to proteins and peptides becoming analytes of increasing importance in the analytical laboratory.

The most commonly used analytical technique for the analysis of protein and peptide purity is reversed phase chromatography (RPC) in combination with UV detection and/or mass spectrometry. As the molecular weight of the protein increases, the selectivity of the RPC separation decreases. Consequently it becomes necessary to introduce complementary separation techniques, e.g., ion exchange chromatography (IEC) for larger proteins.

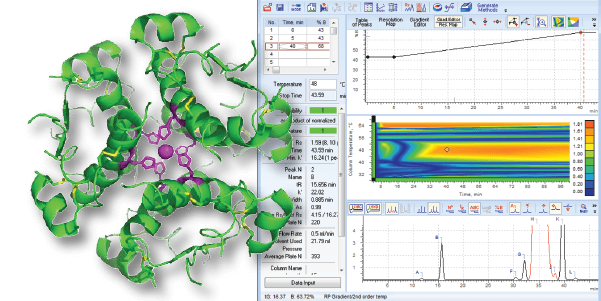

Retention modelling has been successfully used for the method development and optimization of analytical scale separations of small molecules for 30 years2,3,4 and several commercial software packages are available, for example DryLab, ACD/LC Simulator, ChromSword, and Osiris.

A common method development strategy involves a screening of columns and mobile phases that are known to generate large differences in selectivity. The most promising combination of column and mobile phase is then selected and a limited number of experiments conducted in order to build retention models. Subsequently, these models are applied to find an optimal temperature and gradient shape in silico and to assess method robustness.

An important advantage with retention modelling based on theoretical rather than statistical models [i.e., polynomial models based on factorial designs often referred to as Design of Experiments (DoE)], is that a significantly smaller number of experiments are required to fit the models and, in addition, more advanced predictions can be made. For example, it is possible to predict the appearance of an entire chromatogram rather than simply a numerical value which describes the quality of the separation.