Introduction

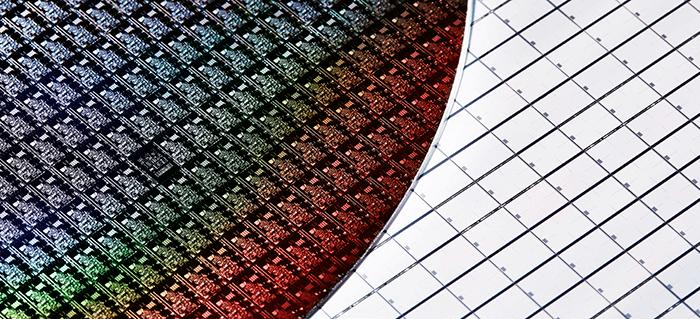

During the production of semiconductor devices, a series of acids are commonly used for a variety of processes. One of the more important chemicals is hydrochloric acid (HCl), whose primary use is to clean the surface of silicon wafers as part of a mixture with hydrogen peroxide and water. As semiconductor devices continue to shrink in size, the purity of the chemicals used in their production increases in importance, as even small levels of impurities can cause device failure. While international SEMI Standards exist for specifying the maximum concentrations of metal impurities (SEMI Standard C27-07081 is specific for HCl), semiconductor device manufacturers are pushing for ever-lower levels, placing the burden on the chemical suppliers. As a result, analytical instrumentation must also be capable of accurate measurements at ever-lower concentrations.

The best technique for measuring low metal concentrations is inductively coupled plasma mass spectrometry (ICP-MS) because of its ability to accurately measure ultra-trace concentrations: ng/L (part-per-trillion) or lower. Nevertheless, under conventional plasma conditions, argon, oxygen, and hydrogen ions combine with matrix elements which can produce polyatomic interferences on elements of interest.