Introduction

Engineered nanomaterials (ENs) refer to the process of producing and/or controlling materials that have at least one dimension in the size range of 1 to 100 nm. They often possess different properties compared to bulk materials of the same composition, making them of great interest to a broad spectrum of industrial and commercial applications.

Recent studies have shown that some nanoparticles may be harmful to humans. A 2009 study in the Journal of Nanoparticle Research showed that zinc oxide nanoparticles were toxic to human lung cells in lab tests even at low concentrations (Weisheng et al., 2009).1 Other studies have shown that tiny silver particles (15 nanometers) killed liver and brain cells in laboratory rats. At the nano scale, particles are more chemically reactive and bioactive, allowing them to easily penetrate organs and cells (Braydich-Stolle et. al., 2005).2

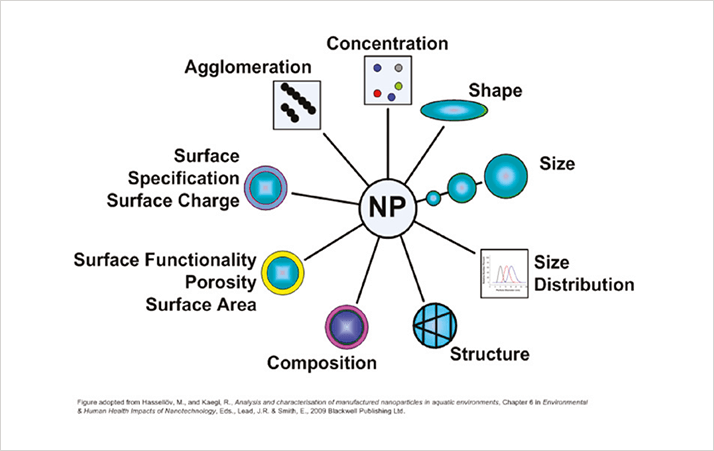

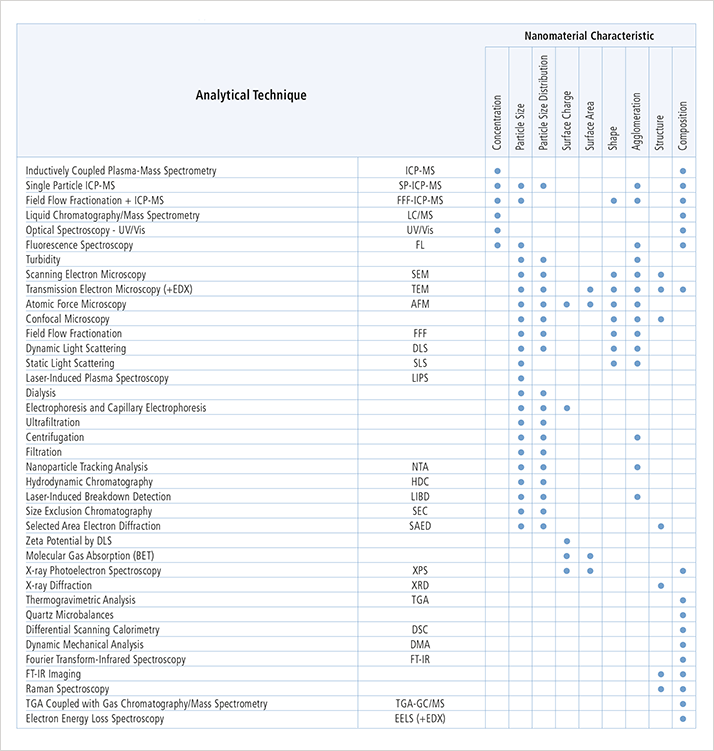

To better understand the impact of nanoparticles, several key characteristics need to be assessed, such as concentration, composition, particle size, shape and other surface characteristics (Figure 1). Given these requirements, several analytical instruments must be used to characterize the material. Table 1 lists the key characteristics and many of the current analytical technologies that can be applied.

Figure 1. Key parameters to characterize nanomaterials (Hasselhov, 2009).3

Figure 1. Key parameters to characterize nanomaterials (Hasselhov, 2009).3 Table 1. Nanomaterial characteristics and applicable analytical technologies.

Table 1. Nanomaterial characteristics and applicable analytical technologies.Inductively coupled plasma mass spectrometry (ICP-MS) is one of the leading analytical techniques capable of measuring and assessing many of these key characteristics of metal-containing particles4. Low detection limits are critical in determining small concentrations of particles in a liquid sample as well as examining the characteristics of individual particles. Additionally, flexibility of instrumental parameters, such as dwell time and speed of the electronics, can influence the quality of data collected. This work explores the capability of the NexION® 350 ICP-MS to measure the key characteristics of manufactured metal nanoparticles.