Summary

This application note describes a Supported Liquid Extraction (SLE) protocol for the simultaneous extraction of 25-OH and 1, α25 di-OH-vitamin D2 and D3 metabolites from serum prior to LC-MS/MS analysis.

Introduction

The method described in this application note achieves high recoveries of the 1, α25 di-OH and 25 OH metabolites of vitamins D2 and D3 from serum. The method is versatile enough to measure both the commonly measured 25 hydroxy metabolites and sensitive enough to quantify the low level 1, α25 dihydroxy metabolites. The method involves SLE extraction followed by a simple PTAD derivatization. ISOLUTE® SLE+ products provide clean, rapid, robust and efficient extraction solutions for a wide range of analytes.

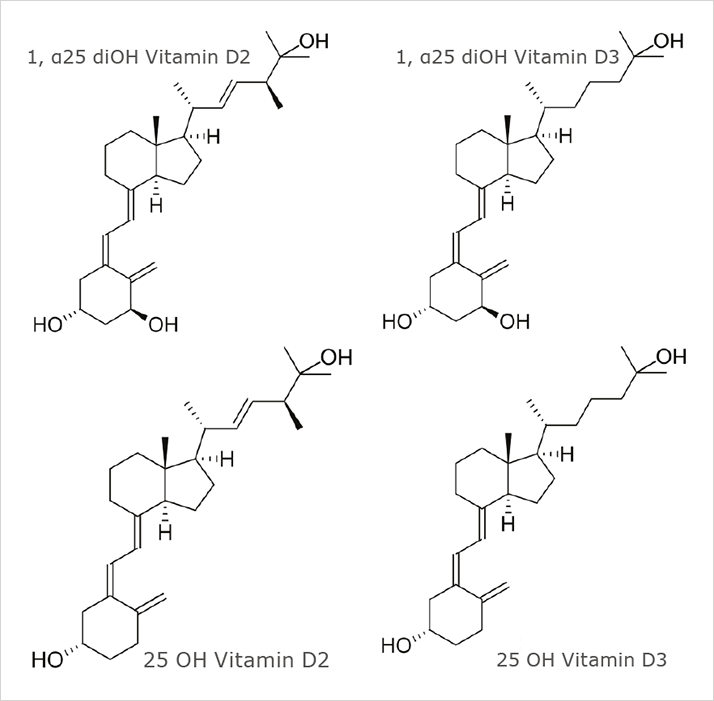

Analytes

1, α25 diOH Vitamin D3, 25 OH Vitamin D3, 1, α25 diOH Vitamin D2, 25 OH Vitamin D2Sample Preparation Procedure

Format:ISOLUTE SLE+ 400 μL Supported Liquid Extraction Plate, part number 820-0400-P01 Sample Pre-treatment:

1. Spike serum samples (and controls) (200 μL) with the required level of internal standard. a. Internal standard addition: Add a 10 μL aliquot containing d6 25 OH Vitamin D3 (640 ng/mL) and d6 1, α25 diOH Vitamin D3 (3.2 ng/mL) in water: methanol (50:50, v/v). b. Samples were left for an hour to enable internal standard equilibration. 2. Pre-treat spiked serum and control samples with 200 μL of water: propan-2-ol (50:50, v/v).

Supported Liquid Extraction

Sample Loading:Load pre-treated sample (300 μL total volume) onto each well. Apply a pulse of vacuum (VacMaster-96 Sample Processing Manifold, 121-9600) or positive pressure (Pressure+ Positive Pressure Manifold, PPM-96) to initiate flow. Allow the sample to absorb for 5 minutes. Analyte Elution:

Elute analytes with heptane (2 x 0.7 mL) and allow to flow under gravity into a 2 mL collection plate (121-5203) containing 100 μL of 0.5 mg/mL PTAD solution in ethyl acetate: heptane (8:92, v/v)2. Apply vacuum or positive pressure to elute any remaining extraction solvent. Post Elution:

Cap the plate and shake for 2 hours1. Dry the wells in a stream of air or nitrogen using a SPE Dry (40 °C, 20 to 40 L min-1) or TurboVap 96 (15 bar at 40 °C for 1 hr). Reconstitute in 100 μL of solvent equivalent to the mobile phase at t zero (30% mobile phase component A, 70% mobile phase component B).