Summary

In this Application Note we describe the use of a continuously-sampling thermal desorber in conjunction with GC/TOF MS to monitor the build-up and decay of fragrances and potential allergens released into indoor air from a plug-in air freshener.

Application TDTS 105

Application TDTS 105Introduction

Air fresheners emit numerous volatile organic compounds (VOCs), amongst which are many fragrance compounds. Developing a near-real-time method of monitoring their build-up and decay in indoor air is of potential interest for manufacturers when formulating their products. Such studies are of particular value in light of a report showing the presence of carcinogens, allergens and other hazardous VOCs amongst the fragrance components in air fresheners1. In this Application Note we look at the near-real-time (NRT) analysis of the compounds released from a plug-in air freshener, using the TT24-7™ Series 2 thermal desorber combined with gas chromatography (GC) and time-of-flight mass spectrometry (TOF MS). The fragrance was allowed to diffuse into a room, and the air was sampled continuously to monitor the compounds released as their concentrations changed over time.

Background to twin-trap thermal desorption

Near-real-time (NRT) analysis based on sample pre-concentration using Markes’ TT24-7 Series 2 thermal desorber (Figure 1) involves the use of two electricallycooled sorbent traps working in tandem2. The use of the second focusing trap enables 100% data capture (i.e. no sampling blind spots), as there is always one trap available for sample collection.

Figure 1: Markes’ TT24-7 Series 2 thermal desorber for continuous monitoring.

Figure 1: Markes’ TT24-7 Series 2 thermal desorber for continuous monitoring.The TT24-7 Series 2 is the latest development in twin-trap thermal desorption technology, featuring:

- Dual-trap continuous monitoring – 100% data capture

- Inert, uniformly-heated flow path offers compatibility for C2–C40 compounds and reactive species

- Wide range of sampling flows (up to 800 mL/min) with quantitative trapping offers high sensitivity

- Highly time-resolved data – cycle times as low as 3–5 minutes if required.

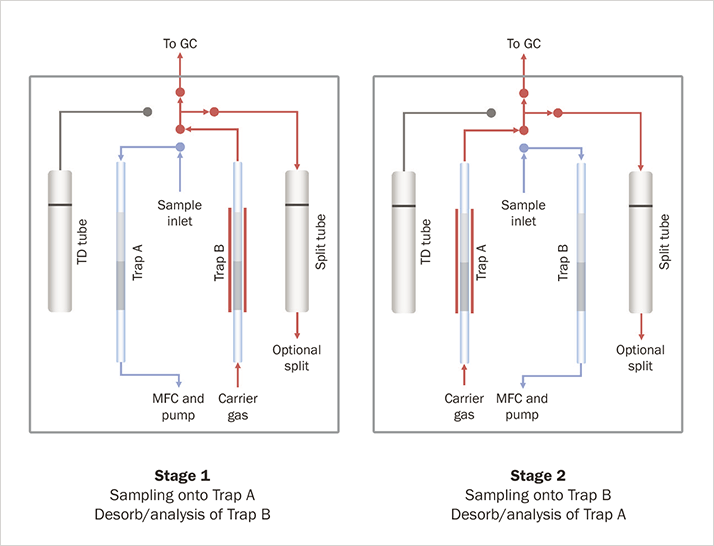

During the sampling process, air is collected onto Trap A, at flow rates between 50 and 800 mL/min. At the end of the designated sampling time the sampling flow is switched to Trap B, and Trap A is desorbed (Figure 2). The cycle is then repeated until the sampling sequence is stopped.

Figure 2: The two-stage operation of the TT24-7 Series 2.

Figure 2: The two-stage operation of the TT24-7 Series 2.Background to time-of-flight mass spectrometry (TOF MS)

The TOF MS used in this study, BenchTOF-dx™ 3, is designed specifically for gas chromatography. A key advantage of TOF mass spectrometers for near-real-time monitoring is their high rate of data acquisition (10,000 full-range spectra per second for BenchTOF-dx). This results in a wealth of detailed spectral information that can either be examined immediately, or retained for future reference – such as screening for previously unsuspected trace-level compounds in complex profiles. BenchTOF-dx is also extremely sensitive, providing full spectral information at levels equivalent to that of quadrupole instruments running in selected ion monitoring (SIM) mode. This makes BenchTOF-dx ideal for trace-level applications. Another advantage of BenchTOF-dx is its production of reference-quality ‘classical’ EI spectra. This allows matching against commercial databases, greatly enhancing the detection and analysis of unknowns as well as target compounds.

Experimental

A laboratory blank was first collected using the TT24-7 Series 2, with desorption and analysis of the first trap commencing at t = 0. At the same time a commercial plug-in air freshener was switched on (at full power) and collection of the fragranced laboratory air commenced on the other trap. The initial chromatogram was therefore representative of the unmodified laboratory air, with each subsequent analysis reflecting the changing fragrance profile in the room. At t = 75 min, the air freshener was switched off and the decay of the fragrance profile determined over 15 subsequent cycles. To maintain cycle times below 20 minutes while ensuring good chromatographic resolution, a relatively short column was used. Trapping parameters were then selected to ensure quantitative retention of the less volatile components that were the key focus of this study, whilst less emphasis was placed on quantitative retention of compounds more volatile than n-hexane. Injection of each sample took place as soon as the GC had returned to its ‘ready’ state after the previous run, giving a new data point every 19 min.