The vast majority of foodstuffs consumed today use packaging to convey information about the product and to protect it during shipping and storage. However, the packaging itself can be a source of contaminants, including residual solvents, monomers and additives. As well as off-odours, such contaminants can also give rise to health concerns, and for these reasons residual solvents in food packaging are regulated in the US (under 21CFR175) and the EU (under EC 1935/2004). The analysis of flexible packaging for the determination of residual solvents typically uses static headspace–GC in accordance with EN 13628-1 or -2.

In this study we demonstrate the fully automated sampling and detection of residual solvents and additives in the headspace of thin flexible packaging for savoury snacks, using syringe headspace sampling with trap-based focusing on the new Centri automated multi-mode platform, in conjunction with GC–MS.

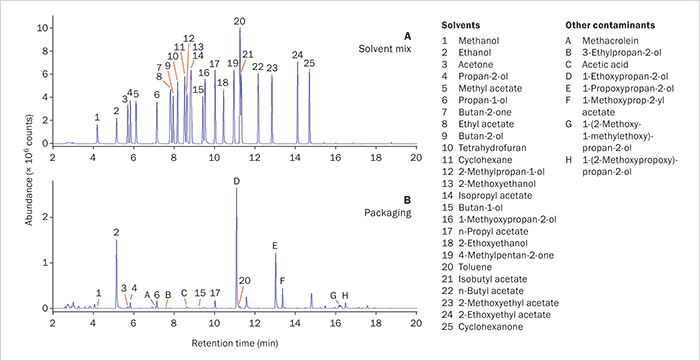

Figure 1A shows the HS–trap GC–MS profile for a standard containing 25 solvents commonly found in food packaging, which shows elution of all components within 15 min. Figure 1B shows the HS–trap profile from a 64 cm2 sample of food packaging, which indicates the presence of a number of solvents and some other components that likely derive from the manufacturing process.

Figure 1: HS–trap GC–MS analysis of: (A) a standard mix of solvents; (B) food packaging, identifying solvents and other contaminants.

Figure 1: HS–trap GC–MS analysis of: (A) a standard mix of solvents; (B) food packaging, identifying solvents and other contaminants.