Introduction

This study outlines the quantitation and characterization of element oxide nanoparticles (Al2O3, and CeO2) commonly used in the nanoelectronics and semiconductor fabrication industry for the chemical-mechanical planarization (CMP) of semiconductor surfaces. CMP is a process of smoothing surfaces with the combination of chemical and mechanical forces in preparation for photolithography. The process uses various element oxide slurries and pressure to chemically and mechanically polish the silicon wafers during the manufacturing of semiconductor devices. In an effort to reduce size of the electronic device and improve the yield of the manufacturing process, CMP slurries consisting of nanoparticles are now in use.

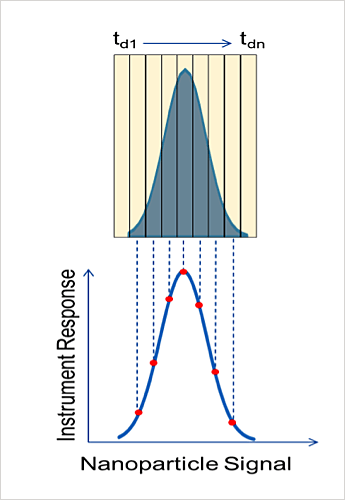

The characterization of the size distribution of CMP slurry nanoparticles, as well as the identification of larger particles, is an important aspect for the quality control of the photolithography process as they can impact the eminence of the silicon wafers. One of the most promising techniques for analyzing metallic nanoparticles is ICP-MS run in single particle mode (SP-ICP-MS). Due to its ability to measure both the dissolved concentrations of analytes and individual nanoparticles, an ICP-MS which is capable of measuring single particles is an ideal instrument for both types of analyses in the semiconductor industry. Because of its sensitivity, flexibility, and analysis speed, SP-ICP-MS is gaining popularity for detecting and measuring inorganic-based nanoparticles. With this technique, nanoparticles are introduced into an ICP and completely ionized, with the resulting ions being detected by a mass spectrometer. The intensity of the signal is related to the particle size; thus SP-ICP-MS provides the user with particle concentration (particles/mL), size and size distribution.In order to ensure that only a single particle is measured at a time, the sample has to be diluted to achieve temporal resolution between particles. The mass spectrometer must be capable of making extremely rapid measurements to ensure nanoparticle detection as the transient signal of a 50 nm nanoparticle can vary on average between 300 and 500 μs, depending on the instrument’s operating conditions and ion optics design (Figures 1 and 2).

Figure 1. Acquiring data faster than the transient signal allows surface area integration of nanoparticle signal.

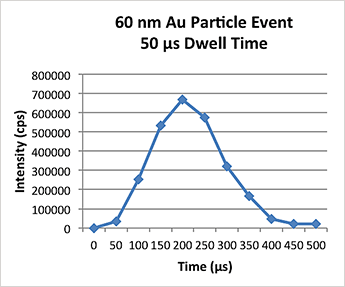

Figure 1. Acquiring data faster than the transient signal allows surface area integration of nanoparticle signal. Figure 2. Signal of one gold 60 nm particle acquired using the NexION 350 ICP-MS operating in single particle mode (50 μs dwell time and no settling).

Figure 2. Signal of one gold 60 nm particle acquired using the NexION 350 ICP-MS operating in single particle mode (50 μs dwell time and no settling).The kind of speed required for SP-ICP-MS is called “transient data acquisition speed”, which is the number of data points the instrument can acquire for a single mass per second. The greater the transient data acquisition speed the instrument provides, the better it is for SP-ICP-MS. The PerkinElmer NexION® 350 ICP-MS operating in single particle mode is able to acquire data continuously, with the elimination of settling times, giving it the ability to acquire as much as 100,000 data points/second.