Introduction

Through peak recycling the user can benefit from a more efficient purification and reduced cost. This article describes when peak recycling is reasonable and the technical specification it requires. By using the length of the column bed multiple times, peak recycling basically elongates the separation length of your column. Most preparative chromatography users know the term but do not necessarily know in which cases this special solution is beneficial. During peak recycling, the peaks are led back onto the column after elution. Thereby, critical peak pairs that run together can be separated further with each cycle. The only requirement for peak recycling is an isocratic separation method since the composition of the eluent needs to stay constant during multiple repetition cycles.

A preparative HPLC system consist of an injection system, a preparative pump, a preparative column, a detector, and a fractionation valve. Chromatography columns for preparative applications are often very expensive. Hence, the user intends to find the best compromise between incurring costs and the obtained separation efficiency. The individual separation challenge and the requirements for the purification thereby set the conditions. That is why complex separation challenges can lead to high expenses and cost-ineffective solutions. In cases where special phases or small particle sizes are required for an efficient purification, not only the cost factor of the preparative column but also the system requirements are limiting. Peak recycling offers a surprisingly simple solution to increase the separation performance without the need for larger investments.

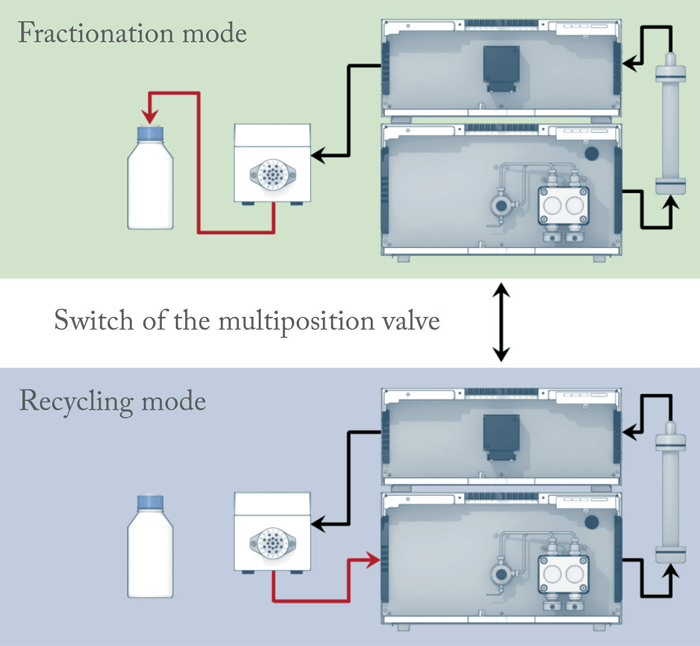

Figure 1 Preparative HPLC system with multiposition valve enabling peak recycling.

Figure 1 Preparative HPLC system with multiposition valve enabling peak recycling.Technical requirements:

The terms “recycling” as well as “recycling mode” are commonly used to describe different types of recycling:

- Time-based peak recycling: This mode is not automated, applicable with any chromatography software, but can be more tedious to configure. Shifts in retention time within one separation can cause differences in purity of the collected fractions.

- Automated peak recycling: With this mode the software controls the recycling by peak height and/or slope. Particular software packages are needed for the automated mode (e.g. OpenLAB CDS EZChrom Edition) offering high level of comfort and safety.

- Solvent recycling: Some software packages like ClarityChrom Prep or PurityChrom offer the so-called solvent recycling as an additional option to save solvent. If the solvent in chromatogram regions without peaks can be considered clean, the solvent is recycled back into the eluent stock. This can be either based on detector signal or time. This mode can considerably lower the operating costs of a system. Merely a multiposition valve and a T-fitting are required to implement the recycling mode. The valve is connected by the T-fitting to the system pump supply via a port (in most cases the second last port of the valve). The valve is switched to that particular port when the system is supposed to skip from normal to recycling mode. Subsequently, the pump will draw the eluent not from the stock but rather recycle the solvent through the entire system (Figure 1). The sample will be pumped in cycles until the valve is switched to fractionation or waste position.