In this article, we look at what today’s rotational rheometers can do, contrasting this with the data delivered by typical rotational viscometers. For some time viscometry has been a mainstream technique for formulation, but those leading the way have long since transitioned to the broader capabilities of rheometry. The choices associated with replacing your ageing viscometer may, therefore, be a long way from like-for-like. Here we provide insight to support an up to- date assessment of the value of upgrading.

Beyond single point viscosity

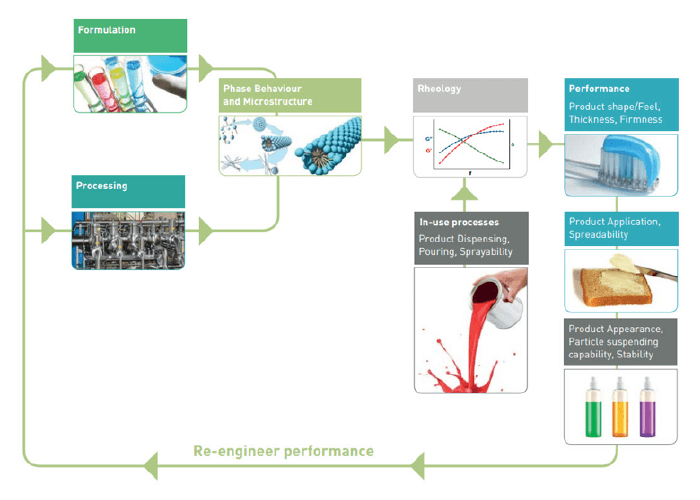

A standard rotational viscometer is an efficient tool for measuring viscosity, at a single point or across a moderate range of shear conditions. However, with the majority of commercial personal care products exhibiting complex, nonNewtonian behaviour, viscosity measurements over a narrow range provide an incomplete picture. Furthermore, viscosity is far from being the only parameter that can usefully be measured to determine product performance, or indeed commercial appeal. Other defining rheological properties include: viscoelasticity; yield stress; thixotropy; and tackiness. Rotational rheometry extends access to the comprehensive measurement of all of these parameters and in so doing has the potential to deliver significant value to formulators. In simple terms the capabilities of a rotational rheometer allow formulators to develop a detailed understanding of performance across all the changing conditions to which a product may be subjected, during manufacture and use. Consumers expect products to behave in a well-defined way and are susceptible to those with ‘kerb appeal’ - moisturisers with a rich, creamy texture, for example, or face washes containing eye-catching suspended particles. Understanding product performance at rest - on the shelf - and when subjected to the shear associated with actions such as smoothing cream across the skin is crucial, and allows formulators to knowledgeably optimise performance, and appeal, long before the product reaches the shelves (Fig 1).