Cell-based therapies have been described as revolutionary for their ability to treat – and even cure – life-threatening diseases, including cancer. But the absence of real-time analytical techniques to understand what is happening in cells at the biochemical level during manufacturing is a challenge in successful development. What’s more, the critical quality attributes (CQAs) that correlate to therapeutic function, performance and potency are unclear and the critical process parameters (CPPs) that impact quality throughout cell therapy manufacturing are largely unknown (1).

“Current real-time process analytical technologies (PATs) are necessary to maintain culture viability, but do not provide information on CQAs that more accurately predict cell state,” says Andrei Fedorov from the Georgia Institute of Technology, USA. “Real-time PATs involving Raman spectroscopy have been effective in monitoring certain biomolecules, but these PATs lack the sensitivity, selectivity and dynamic range to detect a diverse set of biomarkers at low concentrations. The most effective methods to identify CQA biomarkers – namely, high performance liquid chromatography mass spectrometry (HPLC-MS) and enzymatic assays (for example, ELISA), are generally offline, which limits their utility as inputs for feedback control.”

These issues have led to a substandard, low-yield system that relies on analytics at the end of production, which is not only expensive but also time-consuming – and time is a luxury that many patients do not have.

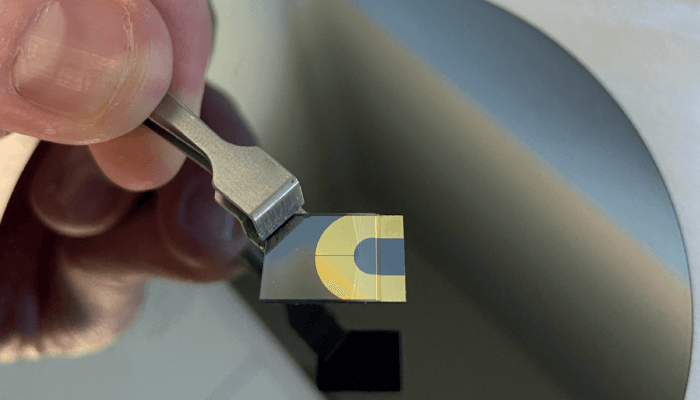

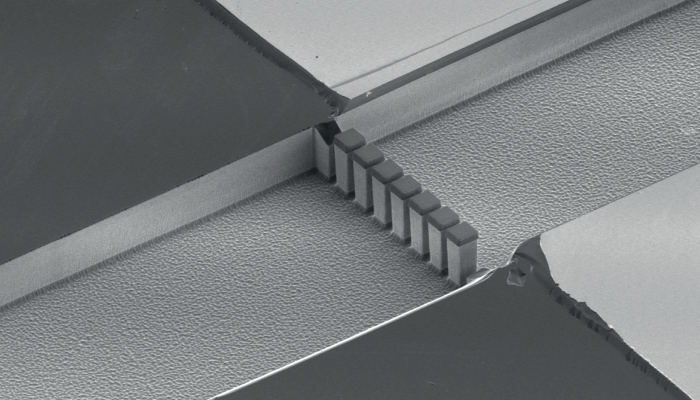

Noting the clear need for new analytical technologies – especially in the manufacture of advanced therapies, Fedorov and his colleagues developed the Dynamic Sampling Platform (DSP) (2) – an integrated sample-to-analysis system that combines a sampling interface, cell processing device, and detection by nanoelectrospray ionization mass spectrometry (nESI-MS).

The team applied their DSP to an intracellular analysis of 1500 human umbilical vein endothelial cells (HUVEC) and were able to detect nearly all proteogenic amino acids, as well as almost all key metabolites identified as HUVEC specific biomarkers.

“The platform has demonstrated the capability to rapidly detect clinically relevant intracellular biomarkers – compounds that were previously identified via conventional HPLC ESI-MS and a long analysis time,” says Fedorov. “DSP also replaces numerous manual handling steps; works with ultra-small cell samples; is capable of self-regeneration for long-term, continuous operations; and is suitable for integration into cell growth bioreactors for direct-from-culture analysis.”

Given its ability to identify new CQAs and monitor known CQAs in biomanufacturing, the researchers believe DSP could help in the development of cell therapies with increased safety, efficacy, potency, and overall quality.

“The ultimate vision is to provide fully automated, multi-omic monitoring of cell manufacturing workflows,” says Fedorov. “The resulting multimodal technology platform would enable biochemical readout of both the extracellular and intracellular environments in real-time. And it would represent a crucial milestone in enabling fully automated quality monitoring with integrated feedback control in cell-based therapy manufacturing – two challenges that must be overcome if the transformative potential of cell therapies is to be fully realized.”

References

- Culberson et al., Lab on a Chip (2021). DOI: 10.1039/d1lc00884f

- Georgia Tech (2021). Available at https://b.gatech.edu/3fCjQyz