Hetero Drugs Limited in Hyderabad, India, is a research-based global pharmaceutical company that focuses on developing, manufacturing and marketing active pharmaceutical ingredients (APIs), intermediate chemicals and finished dosages. Hetero’s manufacturing facilities are cGMP compliant, meeting global standards in terms of infrastructure and systems. Given the fact that Hetero markets its products in over 138 countries worldwide, PIC/S required serious consideration. Hetero’s quality manager, K.V. Ramana Reddy, says, “With traditional methods of HPLC and other lab-based analytical techniques, our materials were being held up in quarantine for long periods of time. I cannot imagine how much time we would lose, if we used such method for 100 percent inspection.”

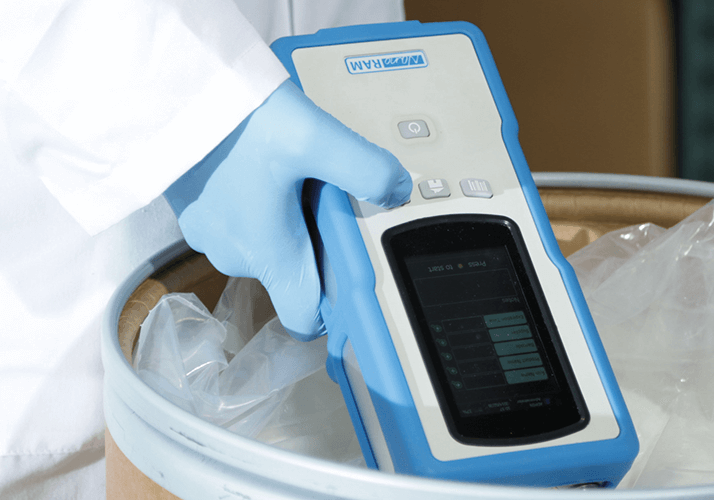

Using handheld Raman spectroscopy (B&W Tek NanoRam), Reddy says it is now possible to complete 100 percent inspection and actually accelerate the process of releasing raw materials into production – repurposing the lab for more important duties in the process. Instead of sending all of the raw materials to the labs for testing, they are inspected as they are unloaded. Moreover, because Raman can test directly through transparent packaging materials, workers no longer need to conduct sampling, which potentially exposes them to dangerous chemicals or contaminating the very raw materials being sent for testing. What’s the turnaround per sample? Reddy says each scan now only takes a few seconds for the operator to complete, and the uniqueness of individual raw material Raman signatures allows for a positive identification. According to Reddy, a device with an easy-to-use touch screen interface allows users to quickly navigate and complete sampling procedures. Various sampling adaptors also mean that the team can work with different types of raw materials, such as solids, liquids, powders, or slurries. And different algorithms allow users to not only identify, but also verify raw materials that may be contaminated or mislabeled.