Introduction

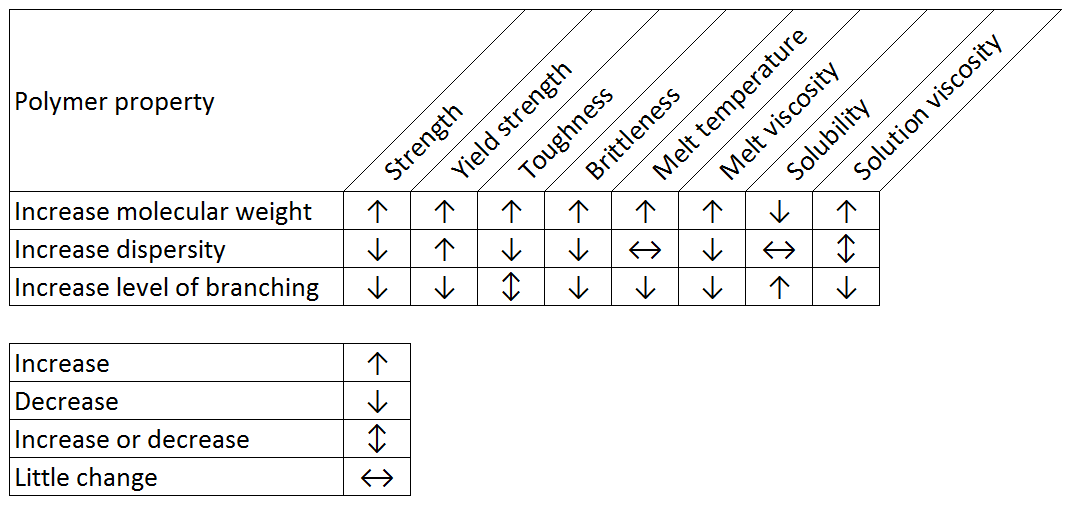

Polymer scientists are continually striving to manufacture products that have the correct characteristics for a given application. By controlling the molecular weight, branching and chemistry, they can tailor a polymer’s properties for a range of applications from containers and fittings to viscosity modifiers and drug delivery vehicles. The challenge here is that the physical properties and behavior of polymer products depend strongly on the properties of the polymer molecules themselves. This is also the case for finished products made from or containing polymers. For example, Table 1 shows how changing properties, such as molecular weight, dispersity and branching, can affect the bulk properties of a polymer. These are general trends and the actual effect will depend on the specific polymer.

Table 1: Effect of molecular weight, dispersity and structure on the bulk properties of a polymer. An essential tool for investigating the molecular weight and molecular weight distribution, molecular size, intrinsic viscosity and structure of synthetic polymers, which all affect how the polymer material will behave, is gel permeation or size exclusion chromatography (GPC/SEC). The principle of GPC/SEC involves separating the sample as it travels through a porous but inert chromatography column matrix. While smaller molecules penetrate the pores more deeply, larger molecules are excluded and thus travel through the column faster. The result is a separation based on hydrodynamic volume. A conventional GPC/SEC system setup, consisting of only an isocratic pump and a Refractive Index (RI) or Ultraviolet (UV) detector provides only a concentration profile of the size-separated sample. As such, any molecular weight measured where the sample and standard are different will only be relative and incorrect. They will also be subject to variation between system and setup, site and columns. This information can only ever be used comparatively at best. With multiple detectors that provide light scattering (LS) and intrinsic viscosity (IV) data, valuable additional information about a sample can be determined simultaneously. Plotting the molecular weight (MW) directly measured from the light scattering detector against the IV directly measured from the viscometer detector produces a Mark-Houwink plot to illustrate the relationship between molecular structure and molecular weight. In this application note, the structural distributions of some common polymers are compared using the Mark-Houwink (M-H) plot. The data are all generated using the Malvern OMNISEC system

Materials and methods

Samples were separated using two Viscotek T6000M columns. The mobile phase was THF stabilized with 300 ppm BHT. Samples were allowed to dissolve overnight to ensure full dissolution. The OMNISEC system was set up as follows: Flow rate: 1.0 mL/min Autosampler temperature: 15°C Column oven temperature: 35°C Detectors temperature: 35°C All system control, data acquisition, data analysis and data reporting were performed using the OMNISEC software (v10 or later). The four samples analyzed in this note are all broad distribution synthetic polymers: polystyrene (PS), polymethylmethacrylate (PMMA), polycarbonate (PC), polyvinylchloride (PVC).Results

To read the full application note, click hereMalvern provides the materials and biophysical characterization technology and expertise that enables scientists and engineers to investigate, understand and control the properties of dispersed systems. These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries. Used at all stages of research, development and manufacturing, Malvern’s instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency. Our products reflect Malvern’s drive to exploit the latest technological innovations. They are used by both industry and academia, in sectors ranging from pharmaceuticals and biopharmaceuticals to bulk chemicals, cement, plastics and polymers, energy and the environment. Malvern systems are used to measure particle size, particle shape, zeta potential, protein charge, molecular weight, mass, size and conformation, rheological properties and for chemical identification, advancing the understanding of dispersed systems across many different industries and applications. www.malvern.com Material relationships http://www.malvern.com/en/ portal@malvern.com