A Hard Problem to Stomach

Gluten is a protein composite found in wheat, rye and barley that gives dough its elastic and chewy texture. For people with severe gluten intolerance or celiac disease, even small amounts of gluten can cause debilitating bloating, abdominal pain and bowel dysfunction as well as fatigue and many adverse non-abdominal symptoms. Maintaining a gluten-free diet is challenging, as wheat derivatives are present in many processed foods like soy sauce and luncheon meats. With gluten-free products more widely available, the need for cost-effective and accurate validation of the grains used to make them has grown.

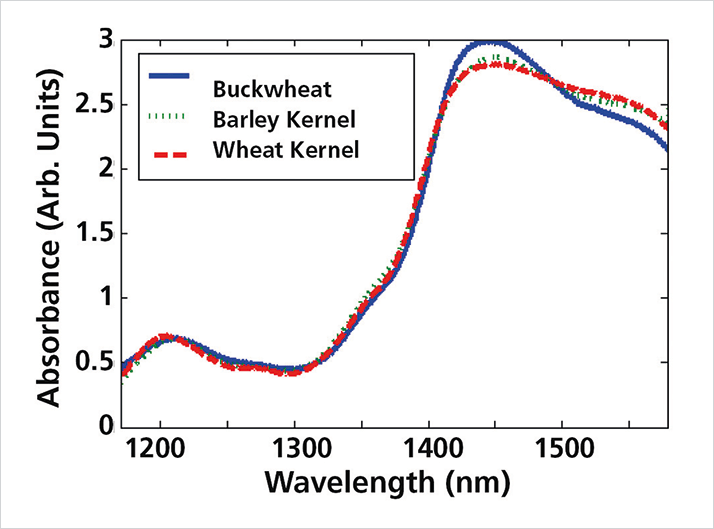

The Kernel of the Problem Gluten-free grains like buckwheat and amaranth are often processed on machinery that also handles other grains. Additionally, contamination can occur in the field if different grains are grown side-by-side. Although contamination is generally below 2%, the stringent requirements defining “gluten-free” necessitate frequent sampling during processing. Each sample of 50,000 kernels must be manually inspected by trained personnel, a process that can take up to an hour. Even then, repeatability is low due to subtle shape and color differences among some kernels. Seeing Things Differently Machine vision alone doesn’t do much better, but it’s a start. When combined with near-infrared spectra of each kernel, classification accuracies rise to >99.5%. Differences in absorbance spectra appear at 1450 nm and 1550 nm due to the unique protein content of each grain variety, and can be fed into predictive analytics algorithms to enable a sorting decision. With the QSorter Explorer – a system incorporating an Ocean Optics NIR spectrometer and a tungsten halogen lamp – the reflection spectrum of each kernel is captured as it passes the “eye” of a high-speed robot, sorting 30 kernels per second.

This Won’t Take Nearly as Long … Approximately 95% of the kernels can be declared “gluten-free” within 30 minutes, while the rest are routed to another bin for visual inspection. This smaller bin contains a mix of offending grains and false positives, i.e., buckwheat kernels that didn’t meet the confidence factor needed for conclusive sorting. Though some manual inspection is still required, it can be completed in 1/20 the time, improving efficiency significantly while still serving as a check for malfunctioning processing equipment. Repeatability error also drops to 2%, 10x better than the estimated human error. A “Gluten-Free” Guarantee Combining NIR spectroscopy and machine vision results in faster, more accurate sorting of grains for gluten contamination, enabling more frequent and reliable quality assurance for cereals destined for gluten-free products.

http://oceanoptics.com/sorting-gluten-intolerance/