Introduction

The biodegradable and biocompatible polymers, PLA and PLGA, are used in many different applications, including food packaging, farming materials, biomedical devices (such as absorbable surgical thread) and implants (such as stents or drug release systems). Three-dimensional printing is another application which benefits from the low melt processing temperature of PLA. Usually, PLA and PLGA are based on monomers from renewable sources, so are considered "green" polymers. By selecting different ratios of lactic:glycolic acid and different molecular structures, some properties can be tailored to meet application needs. Advanced GPC/SEC analysis is an ideal tool for monitoring samples during material synthesis, production of parts and in degradation studies. Advanced multi-detector GPC/SEC can reveal far more information than just numbers for molecular mass averages. Combining the data from refractive index, light scattering and viscometer detectors also provides information about structure and solution properties. In this application note, a selection of different PLA and PLGA polymer samples were analyzed on Malvern's OMNISEC GPC/SEC system, which combines all the detectors described above.Materials and methods

Chromatographic conditions Two LT5000L columns were used for separation. Tetrahydrofuran (THF) was used as solvent for the samples as well as eluent in the chromatographic system. The autosampler, columns and detectors were held at 30 °C. Sample solutions were prepared to concentrations of 1 to 5 mg/mL. The OMNISEC SYSTEM The OMNISEC SYSTEM sets the standard for modern GPC/SEC systems. It consists of two modules: The chromatography module OMNISEC RESOLVE, consisting of degasser, pump, temperature controlled autosampler and temperature controlled column compartment and the temperature controlled detector module OMNISEC REVEAL, equipped with up to four detectors: differential refractive index, UV/VIS absorbance, light scattering and viscometer detector. Both modules of the OMNISEC system ideally match each other to give a comprehensive, robust and easy-to-operate system. OMNISEC REVEAL is also available as an add-on detector module for use with other existing chromatography systems.

Figure 1: The OMNISEC SYSTEM, with RESOLVE module on the left and REVEAL module on the right.

Results

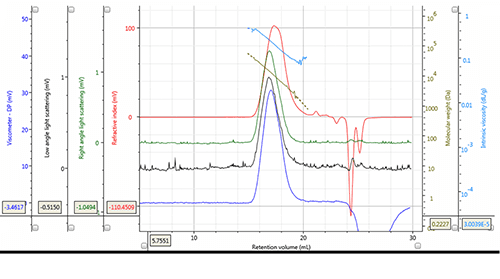

Figure 2 shows a typical chromatogram (peak region) and derived molecular mass and intrinsic viscosity plotted over the retention volume for a PLA sample run on the OMNISEC system.

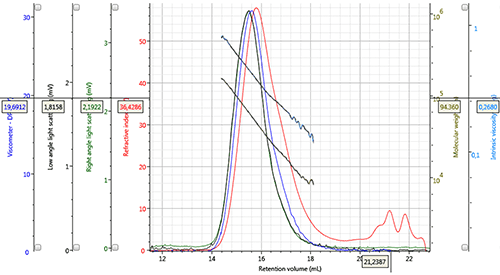

Figure 2: Chromatogram and derived data of PLA Mw = 12,188 g/mol, Mn = 7,487 g/mol, concentration 5.149 mg/mL, 100 μL injection volume Many PLA and PLGA samples are well soluble in THF, a common solvent for many GPC/SEC applications. Unfortunately, the refractive index increment (dn/dc) for this sample/solvent combination is low, at approximately 0.045 to 0.051 mL/g. The refractive index increment determines the response of both refractive index and light scattering detectors. Acetone could be used as an alternative eluent to overcome the low signals for PLA and PLGA, however this would limit the use of the GPC/SEC system for other applications. As THF is a much more widely used solvent and can be used to assess many different types of samples, it would be preferable to use this solvent for the characterization of PLA and PLGA, which is possible with OMNISEC REVEAL due to its enhanced detector sensitivity. The system’s excellent data quality can be seen, both for the detector signals and the derived data, in figures 2 and 3 for PLA and PLGA, respectively.

Figure 3: Chromatogram and derived data of PLGA 50:50, Mw = 44,628 g/mol, Mn = 26,727 g/mol, concentration 2.132 mg/mL, 100 μL injection volume

Molecular structure

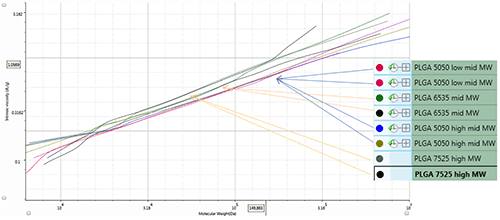

The sensitive viscometer inside OMNISEC REVEAL allows determination of intrinsic viscosities across the peak. By looking at the Mark-Houwink-plot (log [η] vs log MW), structural differences in the samples can be revealed. Differences in the composition of PLGA samples do show up here as the coil density will be slightly different due to the compositional changes. Figure 4 shows the Mark-Houwink-plot for duplicate injections of PLGA samples with 50:50 (two samples with different molecular mass), 65:35 and 75:25 compositions of lactide:glycolide. The Mark-Houwink-plots clearly divide up into three groups, corresponding to the composition of the samples: The 75 % lactide sample corresponds to the highest curve, the 65 % lactide sample lies in the middle and the 50 % lactide samples form the lowest group of curves on the Mark-Houwink-plot.

Figure 4: Mark-Houwink-plot for PLGA samples

Reliable data

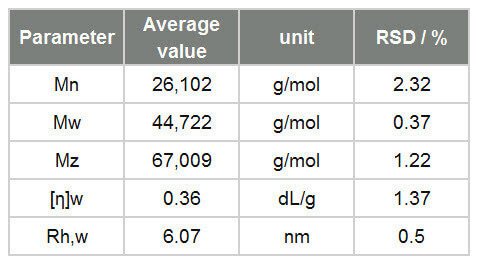

OMNISEC RESOLVE incorporates a new autosampler, which is specially adapted to handle the viscous sample solutions that are sometimes used in GPC/SEC analyses. Reliable injections are the basis of reliable measurements. 10 repeat injections of 100 µL were performed on a PLGA sample with 50 % lactic acid content at a concentration of 2.132 mg/mL . The following table shows the measured parameters together with their respective relative standard deviation.

The recovery showed a relative standard deviation of 0.53 % for those ten adjacent injections. Overall, this shows the excellent repeatability of the data obtained.

Discussion

The data presented in this application note shows that determination of molecular mass, intrinsic viscosity, hydrodynamic radius and molecular structure is both easy and reliable using the OMNISEC GPC/SEC system. The data allows clear differentiation between different compositions of PLGA by the different properties the samples exhibit in solution. The excellent reproducibility of the results can only be achieved by working with a reliable chromatographic method and a reliable chromatographic system with high performance detectors.As the final properties of PLGA products will be heavily dependent on factors such as the molecular weight and composition of the PLGA, these kinds of measurements allow for much greater understanding and control over those final properties. For instance, the degradation time of biodegradable sutures or the release profile of drugs from a delivery implant could all be controlled with greater precision using this information. Such measurements are becoming essential as the demand for improved control over drug delivery and biomedical applications increases.

Malvern provides the materials and biophysical characterization technology and expertise that enables scientists and engineers to investigate, understand and control the properties of dispersed systems. These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries. Used at all stages of research, development and manufacturing, Malvern’s instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency. Our products reflect Malvern’s drive to exploit the latest technological innovations. They are used by both industry and academia, in sectors ranging from pharmaceuticals and biopharmaceuticals to bulk chemicals, cement, plastics and polymers, energy and the environment. Malvern systems are used to measure particle size, particle shape, zeta potential, protein charge, molecular weight, mass, size and conformation, rheological properties and for chemical identification, advancing the understanding of dispersed systems across many different industries and applications. www.malvern.com Material relationships http://www.malvern.com/en/