Sulaf Assi is a lecturer in forensic sciences at the Faculty of Science and Technology at Bournemouth University, UK. With an extensive background in pharmaceutical analysis, she brings her knowledge and skills to bear on instructing the forensic investigators of tomorrow in the use of handheld vibrational spectroscopy, Raman, near-infrared and infrared. Assi is also involved in the research of different aspects of forensic sciences: counterfeit products (medicines, cosmetics, tobacco and alcohol), drug abuse and misuse, novel psychoactive substances, analytical (chromatographic and spectroscopic) techniques, handheld instruments and multivariate data analysis.

“Handheld spectroscopy is excellent for counterfeit medicine analysis. It is simple, non-destructive and quick. Being fully portable, you have no trailing cables and you can generally get around four hours out of a single charge of the on-board battery. This is important particularly when you are analyzing samples taken from street markets, for example. You do not want to destroy them, as the counterfeits are evidence. You can take the instruments to precisely where you need to be,” says Assi.

“Admittedly, you do need to do a lot of chemometrics; building spectral libraries, particularly for counterfeit medicines is challenging. So far, we have about 300 examples we have taken from the world market – and then you have to optimize your algorithms – both linear and probability-based algorithms – according to the sample you are analyzing.” Assi says that Viagra and Valium (benzodiazepine) are among the most counterfeited medicines on the world’s black market. However, counterfeiting could still be encountered with any medicine class and any formulation type. The World Health Organization (WHO) typically defines counterfeit drugs as those that contain no active pharmaceutical ingredient (API), low/excess API, no API or even fake packaging.

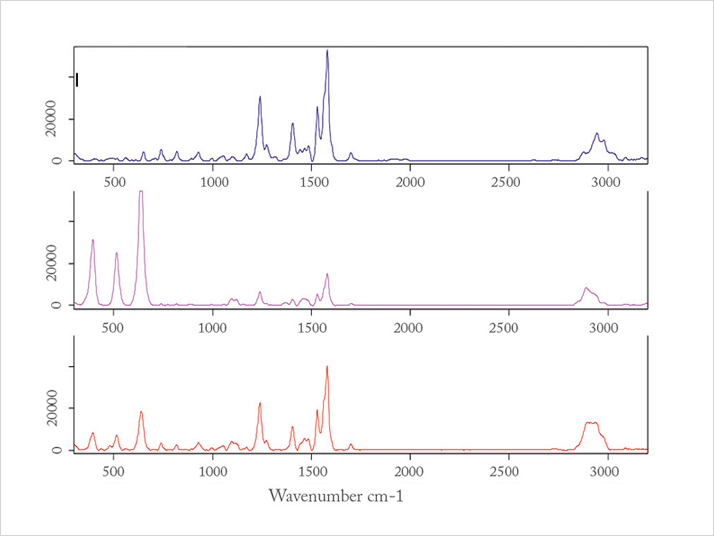

“We found one particular Viagra tablet where the concentration of sildenafil citrate was much higher than the authentic medicines. I could tell all of this using the handheld Raman spectroscopy. By correlating the tablet’s spectra to the sildenafil citrate spectrum in the library, I could see that the counterfeit had more peaks corresponding to the high sildenafil citrate concentration. Likewise, I could tell that these counterfeit tablets had a thin coating which was clear when correlating their spectra to the spectrum of titanium dioxide (a main ingredient in the coating of Viagra tablets),” says Assi. “I currently use a handheld Raman spectrometer (Bruker Bravo) that subtracts the fluorescence you get with both thick and thin tablet coatings. The spectral resolution is very good and the range extends to around 3200 cm-1, which is critical. When dealing with counterfeit medicines, everything counts – every peak is an important characteristic and can indicate something important.”

In chromatography, analytical scientists may focus on a single peak of interest and disregard the rest, but with spectral analysis of a counterfeit product the whole spectrum is a signature of the material. Assi uses the handheld instrument in both the laboratories and onsite. She teaches second year forensic science students, supporting another lecturer’s unit. She also makes use of the technology with Master’s degree students studying crime scene management and forensic science. “Students get trained as forensic investigators and on the Master’s course they have to take part in a simulation exercise at Bournemouth airport where they investigate suspicious powders and fibers found on board an airplane. We also offer three-year forensic science, forensic investigation and forensic biology courses where students have placements throughout. They also get a final project, with many of them choosing to use Raman and/or infrared spectroscopy. For example, a year one student has been comparing Raman with infrared to optimize our cosmetic library and another used Raman for detecting herbal sleep remedies in alcoholic beverages used as date rape drugs,” says Assi.

Handheld FTIR spectrometers have proven capable of measuring thermal damage in various carbon fiber composites used in modern aerospace applications. In this case, Boeing used a handheld FTIR (Agilent 4300) to support a partner company that manufactures and supplies large composite parts after a thermal exposure incident occurred during a routine composite repair. According to Paul Vahey, an analytical chemist at Boeing, “A faulty heat blanket subjected a portion of a large composite part to substantial excess heat. Based on a visual inspection alone a hole would have been cut through the part to remove all the affected composite material. Though the large part was worth several hundred thousand dollars, it would have been scrapped because a through-thickness patch would have been unacceptable to the airline customer.”

The solution was to use handheld FTIR directly at the site to evaluate the composite material on both the inner and outer surfaces. Vahey explains, “While effects of heating were visible on both sides, objective information from the FTIR indicated the resin was not weakened in the discolored back side of the heated area. By scarfing one layer at a time and measuring the underlying layer, it was necessary to remove less than half of the plies under the runaway heat blanket. Non-destructive FTIR data was confirmed by thermal analysis, such as glass transition temperature and differential scanning calorimetry.” Composites are now replacing metal components in other industries too, such as sports cars, motor racing, and boating. These booming composite applications demand more refined diagnostic tools to detect problems and confirm the chemical integrity of the material. Handheld FTIR instruments, like the one used by Boeing, are optimized for such tasks and provide the capability of at-site, non-destructive measurements, enabling users to make real-time decisions about quality, performance, damage and degradation. Vahey says handheld technology provides several benefits. “One important advantage of FTIR was the immediate availability of the data, which allowed the repair to move forward. The portable nature of the handheld FTIR also allowed us to respond quickly, especially as the facility did not have on-site spectroscopy equipment. Indeed, FTIR provided objective data for the engineering department to base decisions upon, instead of making educated guesses on visual information alone. If we had to wait for thermal analysis of each layer, the repair process would have required days for the analysis, instead of hours. In the end, we saved time and money by not scrapping a large composite part that would have added substantial amount of flow time, labor, and materials to replace.”

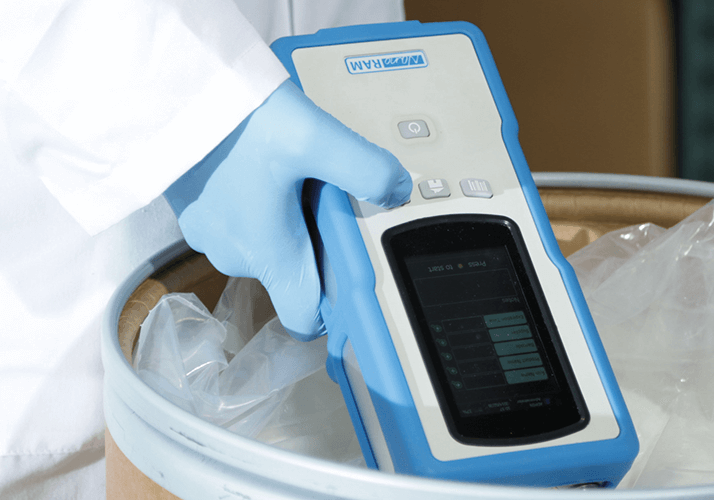

Hetero Drugs Limited in Hyderabad, India, is a research-based global pharmaceutical company that focuses on developing, manufacturing and marketing active pharmaceutical ingredients (APIs), intermediate chemicals and finished dosages. Hetero’s manufacturing facilities are cGMP compliant, meeting global standards in terms of infrastructure and systems. Given the fact that Hetero markets its products in over 138 countries worldwide, PIC/S required serious consideration. Hetero’s quality manager, K.V. Ramana Reddy, says, “With traditional methods of HPLC and other lab-based analytical techniques, our materials were being held up in quarantine for long periods of time. I cannot imagine how much time we would lose, if we used such method for 100 percent inspection.”

Using handheld Raman spectroscopy (B&W Tek NanoRam), Reddy says it is now possible to complete 100 percent inspection and actually accelerate the process of releasing raw materials into production – repurposing the lab for more important duties in the process. Instead of sending all of the raw materials to the labs for testing, they are inspected as they are unloaded. Moreover, because Raman can test directly through transparent packaging materials, workers no longer need to conduct sampling, which potentially exposes them to dangerous chemicals or contaminating the very raw materials being sent for testing. What’s the turnaround per sample? Reddy says each scan now only takes a few seconds for the operator to complete, and the uniqueness of individual raw material Raman signatures allows for a positive identification. According to Reddy, a device with an easy-to-use touch screen interface allows users to quickly navigate and complete sampling procedures. Various sampling adaptors also mean that the team can work with different types of raw materials, such as solids, liquids, powders, or slurries. And different algorithms allow users to not only identify, but also verify raw materials that may be contaminated or mislabeled.