Introduction

OMNISEC REVEAL is the new top-of-the-range gel-permeation/size-exclusion chromatography (GPC/SEC) multi-detector module from Malvern. It combines refractive index, UV/Vis absorbance, light scattering and viscometer detectors to measure concentration, molecular weight and intrinsic viscosity with unparalleled sensitivity and accuracy as part of a GPC/SEC system. OMNISEC REVEAL is available as a detector-only option, which can be connected to any GPC/SEC system. Alternatively, it forms part of a complete OMNISEC GPC/SEC system which includes OMNISEC RESOLVE, Malvern’s dedicated separations module. With OMNISEC REVEAL, any GPC/SEC system becomes a powerful tool for complete molecular characterization of synthetic polymers, natural polymers and polysaccharides, and proteins.OMNISEC REVEAL

OMNISEC REVEAL is an advanced detector module. It contains all four detectors in a single integrated unit. It can be run on its own as a plug-and-play detector when combined with any existing GPC/SEC system (simply connect flow to the inlet, an injection trigger and analogue signals) or as part of a complete system including OMNISEC RESOLVE, the chromatography module. When running, all of the data from the current injection is stored on instrument. This means that should the connection between OMNISEC REVEAL and the PC be lost during acquisition, any data missed by the software is downloaded upon re-connection so the full chromatogram is saved. In this way, the risk of data loss from a loss of connection is greatly reduced. OMNISEC REVEAL includes the following 4 detectors in series:Refractive index

The differential refractive index detector is a robust design that places it as the very first detector with the others following in series. This maximizes the sensitivity of the other detectors, in particular, the viscometer, and helps to minimize the band broadening between the detectors, again improving measurement accuracy. Precise temperature control and high quality electronics all contribute to exceptional baseline stability improving sensitivity and accuracy of the concentration measurements.UV/Vis Absorbance detector

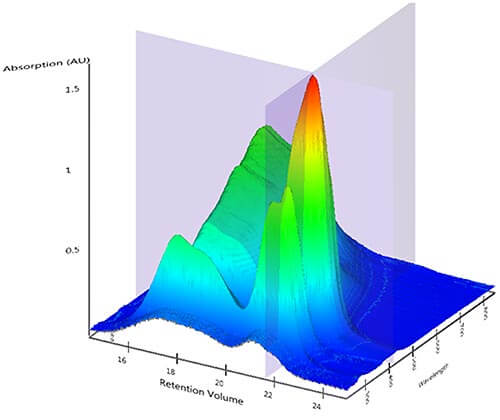

The UV/Vis absorbance detector is a photo-diode array capable of making measurements from 190-900 nm and therefore covers the full UV and visible range. This widens the potential applications range to include samples such as polythiophenes which may absorb light outside the UV range.

Figure 2: A 3D representation of the absorbance data from the UV/Vis PDA detector.

Light scattering

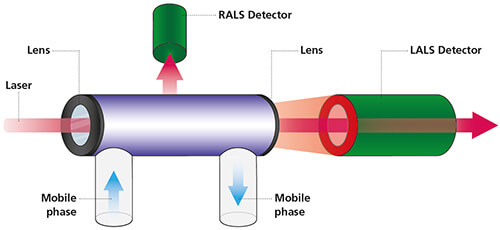

The light scattering detector in OMNISEC REVEAL is the most sensitive on the market. Its sensitivity enables measurements of molecular weights as low as 200 Da or injection masses as low as 100 ng of material. This sensitivity enables it to measure low molecular weight samples; novel polymers with low dn/dc; or extremely small amounts of precious samples such as proteins. The light scattering detector is a successful RALS/LALS design pioneered by Viscotek. The light scattering detector determine molecular weight by measuring the intensity of the light scattered by the sample. A RALS (right-angle light scattering) detector measures the scattered light at 90° and has excellent sensitivity due to its simple optical design. It can measure the molecular weight of molecules below approximately 10-15 nm radius. The LALS (low-angle light scattering) detector measures the scattered light at just 7°. A LALS detector can accurately measure the absolute molecular weight of all molecules without extrapolation or fitting of the angular data. The combination of RALS and LALS offers the sensitivity of a RALS detector with the accuracy of a LALS detector to offer excellent molecular weight measurements across the whole range addressed by GPC/SEC. The additional benefit of the RALS/LALS design is that the flow cell volume is just 18 µL. This minimizes band broadening and tailing (dispersion) that occurs between detectors.

Figure 3: The RALS/LALS detector

Viscometer

The viscometer in OMNISEC REVEAL is based on the original Wheatstone bridge design patented by Viscotek but has been reengineered to improve its usability and performance. The new viscometer includes two major improvements over previous designs. The first is the exchangeable viscometer bridge. In older viscometer designs, a blockage in one of the capillaries required an expensive service call or possibly even a return-to-base repair. OMNISEC REVEAL’s viscometer now contains a user exchangeable capillary bridge allowing easy replacement in just 10 minutes. This dramatically reduces the cost of a failure, both financial and in downtime. Secondly, the viscometer features fully-automated bridge balancing. This feature is software controlled - by adjusting the resistance on one side of the viscometer bridge it can balance a new bridge or re-balance an old bridge. This makes installation of the new viscometer bridge trouble-free and can even extend the life of a partially blocked bridge. The digital viscometer’s transducers are of a 316 stainless steel piezo-resistive design to maximize the solvent compatibility and pH range. They are protected by built in transducer over-pressure protection which opens a purge valve if the pressure is too high to protect them from damage. The overall result is a new generation of viscometer technology and a dramatic improvement in viscometer usability. Click here to access the PDF of this technical noteMalvern provides the materials and biophysical characterization technology and expertise that enables scientists and engineers to investigate, understand and control the properties of dispersed systems. These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries. Used at all stages of research, development and manufacturing, Malvern’s instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency. Our products reflect Malvern’s drive to exploit the latest technological innovations. They are used by both industry and academia, in sectors ranging from pharmaceuticals and biopharmaceuticals to bulk chemicals, cement, plastics and polymers, energy and the environment. Malvern systems are used to measure particle size, particle shape, zeta potential, protein charge, molecular weight, mass, size and conformation, rheological properties and for chemical identification, advancing the understanding of dispersed systems across many different industries and applications. www.malvern.com Material relationships http://www.malvern.com/en/