Click here to read part one of our two-part series on NASA’s recently retired DC-8 airborne laboratory, which features Armin Wisthaler, Instrument Principal Investigator of the NASA Tropospheric Composition Program. Wisthaler tells us about the challenges involved, his lessons learned, and NASA’s plans for a successor to the DC-8.

Here, Tobias Reinecke, R&D scientist at IONICON, tells us what it’s like operating and maintaining instrumentation onboard a flying laboratory – sometimes with members of the press looking over your shoulder…

How did you get involved with the “flying lab”?

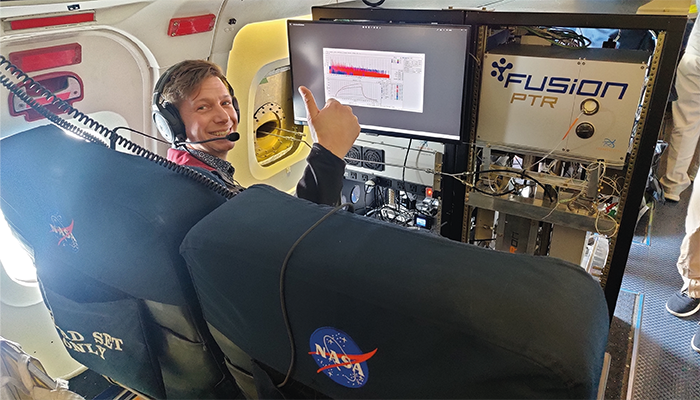

It started with IONICON’s collaboration with the University of Innsbruck on the pSAT project, funded by the Austrian Research Promotion Agency (FFG). As one of the developers of the FUSION PTR-TOF at IONICON, my involvement started with the instrument development to ensure flight worthiness and reliability of this specialized version of the instrument.

The initial integration phase at NASA’s Armstrong Flight Research Center was focused on the physical setup but also included calibration and testing of the FUSION instrument.

Following the successful integration, I participated in the first series of science flights conducted in the Philippines. This phase allowed us to test the capabilities of the FUSION PTR-TOF in real-world conditions, ensuring that the data collection processes are both robust and reliable.

Which instruments do you work with?

Working aboard the DC8, I engaged with two IONICON instruments. The FUSION PTR-TOF VOC analyzer, which is based on proton-transfer-reaction mass spectrometry (PTR-MS). This technology is particularly adept at measuring volatile organic compounds (VOCs) in the air. The analyzer’s role aboard the DC8 is to provide real-time data on the composition of the atmosphere’s VOC content, which is vital for understanding the sources, transformations, and sinks of VOCs in the atmosphere.

The second instrument I work with is the IONICON FUSION PTR-TOF 10k, equipped with a CHARON particle inlet system. This instrument extends the capabilities of traditional PTR-MS to include the measurement of particulate organic compounds. Aerosols play a significant role in atmospheric processes, including cloud formation and radiative balance, making their study essential for understanding atmospheric dynamics and climate change.

What does your day-to-day look like?

A science flight day starts at least three hours before takeoff. This window is crucial for performing the startup procedures on the instruments involving heating instruments to operational temperatures, pumping to achieve the required vacuum levels, and performing calibration checks to ensure accuracy. The final step before takeoff involves transferring the power sources from ground power to aircraft power, including a short period where there is no power available and all scientific devices are powered only by their uninterruptible power supplies (UPS).

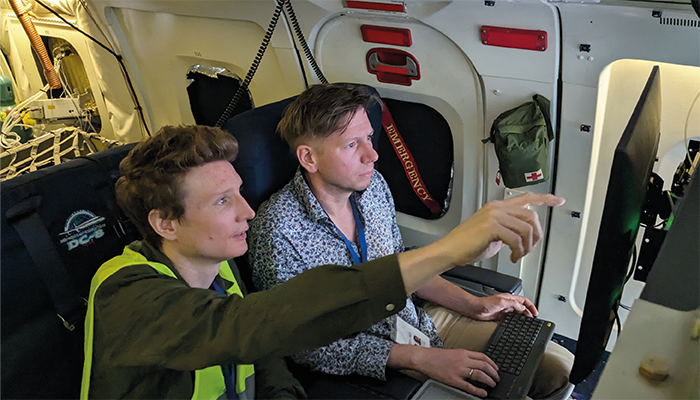

The flight pattern is designed to capture a wide range of atmospheric data, starting from high altitude (above the boundary layer) and then descending to lower altitudes, including low approaches and missed approaches to sample air close to the ground. The operator’s focus during the 8h flights is on monitoring the online data from the instruments, comparing them with data from other instruments, and checking the performance of the setup.

After landing, final calibration measurements are performed and, subsequently, the instruments are shut down in a controlled manner to ensure that they are ready to operate in the next flight.

What are the main challenges – and how do you tackle them?

Challenges stem from the unique and sometimes harsh conditions encountered during flight. The instruments must withstand heavy G-forces and cope with rapid pressure changes, which are common during takeoff, landing, and certain flight maneuvers. The heat inside the airplane, especially when combined with the heat generated by all instruments aboard, poses a significant challenge; high temperatures can cause pumps and electronics to overheat.

Additionally, when the aircraft is on the ground, shutting down the instruments is necessary. This includes turning off all heaters and breaking the vacuum because there is no power available to continue operation. These numerous shutdowns and startups are in stark contrast to a standard laboratory environment. The frequent temperature cycles impose a significant stress on the internal components and it is crucial to prevent the introduction of dust and humidity to ensure long term functionality.

Do you have any anecdotes?

On one of the maintenance days, I had to open up the instrument for a planned maintenance task. This is usually a routine operation in the laboratory. But performing this task on an airplane with a temperature above 40 °C is challenging. Additionally, it was media day where the international press was filming, putting a little extra pressure and attention on my task!

Overall, what’s it like working in a “flying lab”?

It has been an extraordinary opportunity to take our newest instruments, developed and initially tested in the controlled environment of our lab in Innsbruck, and expose them to the real-world – and often harsh – conditions of atmospheric research in flight. This transition from the lab to the sky serves not just as a test of our technology but also as a significant leap towards validating our scientific contributions. The feedback received from these tests is invaluable, offering insights that drive further innovations and improvements in our technology.

Tobias Reinecke | Credit product images - Credit: Supplied by Tobias Reinecke