The problem

How can we give inexperienced trainees or potential users the chance to “play” with gas chromatography optimization – when there is no access to a GC system?

Background

When chemistry students cover physical separation methods, they typically learn about filtration, gravimetry, distillation and chromatography. However, the chromatography they are exposed to is very generic – at best a few injections are done by the instructor and the result are explained. When it comes to optimization methods, there is very little flexibility, as students are not usually allowed to work with a real GC.

Traditionally, you need plenty of “hands-on” GC experience to truly understand the impact of parameters, such as oven temperature, flow, phase chemistry and column dimensions, on separation and analysis time. Back in my university labs, there were usually only a few gas chromatographs and columns available, so students could not spend the hours it would take to run experiments with various parameters – there is no time to “play.” And this represents a major roadblock to learning.

The solution

The solution is simple: a web program called “ProEZGC.” By simulating separations, it allows the user to change any GC parameter online and see how separations are affected. The program is free for anyone to use and calculates retention times based on real measurements.

Now, being a “hardcore” chromatographer, the word “simulation” immediately puts me on my guard, but once I learned how the program could benefit users, I realized that it is a very cool tool. Actually, it is designed for anyone to use, but I think it has a special value for students.

When a parameter is changed in ProEZGC, the result is displayed immediately. You can change the oven temperature, the column flows, the column dimensions and even the type of carrier gas and immediately see the predicted impact on the separation. In short, ProEZGC offers great educational value, it is fast and interactive, and – as the name suggests – it is easy (EZ) to use.

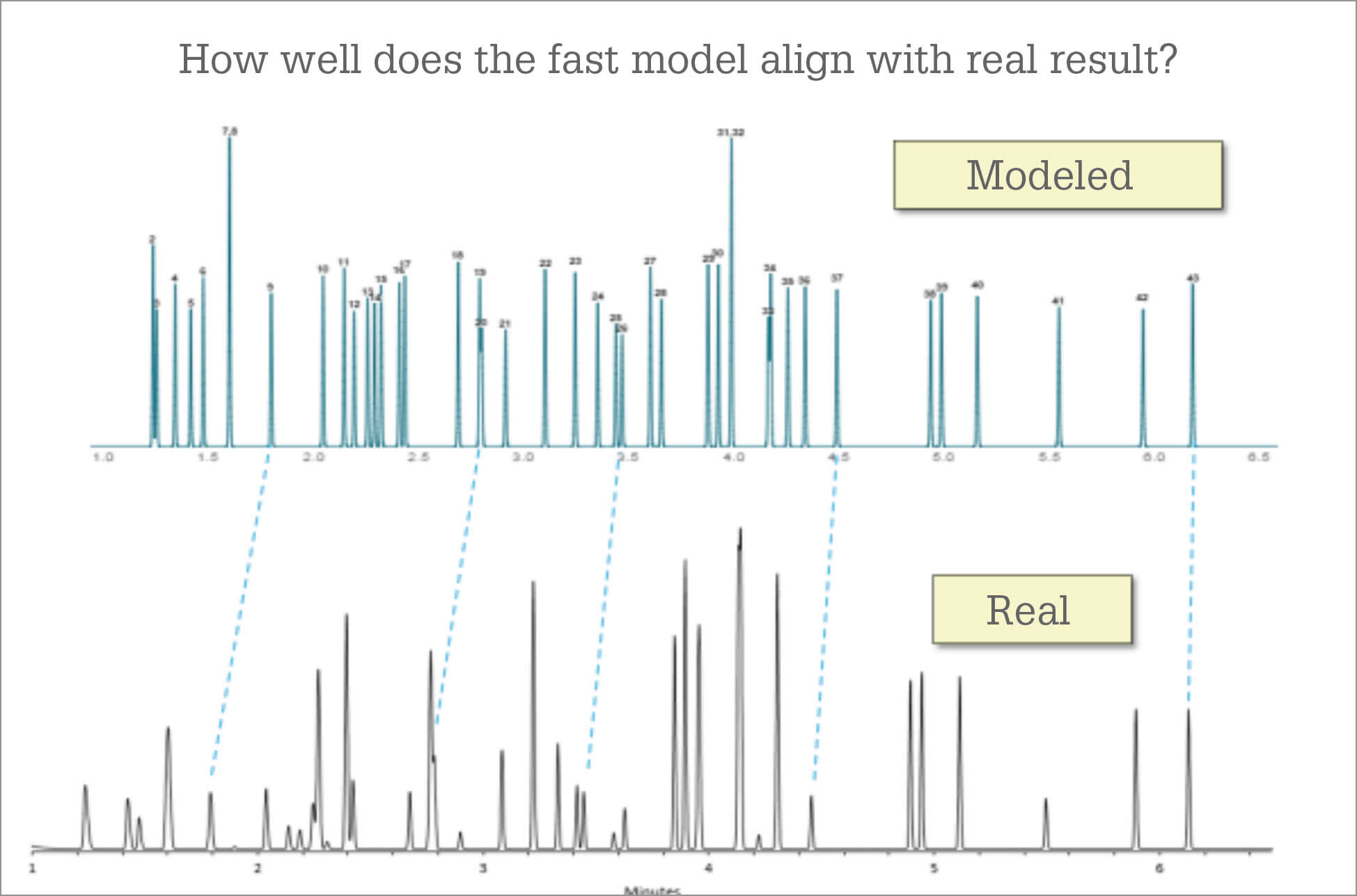

Equally importantly, it is also true to life; Figure 1 compares predictions from ProEZGC with the real separation, showing how accurate the model is. So how does it work?

In GC, we are lucky to have only a limited number of parameters that can influence separations. There is “selectivity,” which depends on interactions of analytes with stationary phase. As pi–pi and van de Waals (London) interactions are dependent on temperature, changes (in temperature) will also have an impact.

Then we have “retention,” which depends on film thickness, column dimension, temperature and carrier gas velocity (and this velocity depends again on column dimension, type of carrier gas, pressure and temperature).

Once the relation of retention versus temperature for a component is known on a specific stationary phase, one can predict the elution time/temperature and create a model. To make a prediction, one must accurately measure the retention of the component under exact, defined temperature-programmed conditions.

A chromatogram of a list of analytes can be generated and optimized in the program, and when the same conditions are copied in real life, the same result can be expected. The power behind the ProEZGC is a huge database of nearly 8,000 components and how they behave on different stationary phases. As the main factors behind retention are temperature and interaction, the retention of components is measured on stationary phases using several defined temperature programs. This way, it is possible to model elution times very accurately.

ProEZGC is a very useful tool for teaching chromatography to students. It can be applied to experience the basics of GC on a large list of analytes (the effect of columns stationary phase and dimensions, oven program) but it can also be used for teaching about method translation in more advanced level chromatography lessons.

A well-known drawback in teaching is the limited time to practically coach students on the lab. Therefore simulation programs are a very important tool to help students visualize and understand the consequence of choosing one or other parameter. This tool pushes students to understand chromatography and stimulates their interest.

Third year students had a practical assignment that involved developing their own (non-validated) method to analyze BTEX by GC-MS in just six hours. The students approached the practical by exploring peer-reviewed literature, before using ProEZGC to translate the methods they identified to the column type and system that exists in the lab – with great success.

The disadvantage of using any simulation is the risk that users fail to understand the reasons behind their work, but ultimately this is the responsibility of educators. The advantage is obvious – motivating students by helping them to visualize the effects of parameter changes on predicted chromatograms. I’ll add that it can also prevent frustration and wasted resources in the lab when time is limited.

I first got excited about this program a few years ago, when there was a helium shortage. I started to look at using nitrogen as the carrier gas in my GC. To compensate for loss of speed, I chose to use a shorter narrow bore (20m x 0.15mm ID) column instead of the standard 30m x 0.25mm, and ran this at a slightly higher flow, so I would get the exact same analysis times as obtained with helium. Using the program, I was able to predict the separation and the results matched very well with the eventual outcome. We tested the concept for four different GC phases and four different component classes (fragrances, PAH, pesticides and dioxins) – and all were a perfect match.

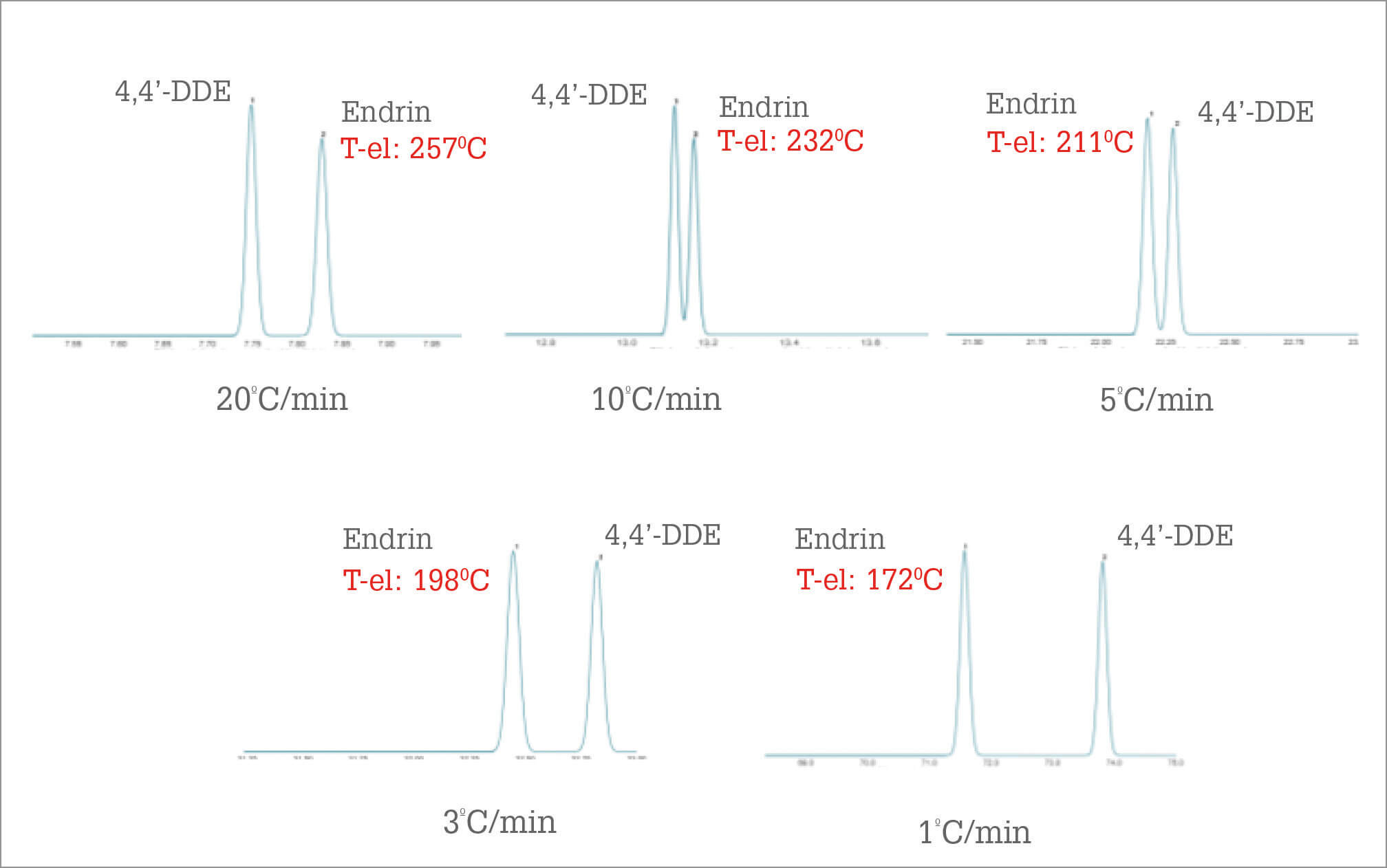

But for students, it’s a valuable tool to see how separations are impacted by different parameters, not just in terms of time of analysis, but also peak sequence and separation. When temperature programs or column flows change, the elution temperatures of the eluting components change. As a result, the separations (elution times/orders) can change. Some separations improve, some separations get worse or can even disappear – a fact that is under-appreciated even by experienced scientists. For example, Figure 2 shows how separation between the pesticides endrin and 4,4’-DDE changes when different temperature programming is used. Elution temperatures for endrin change from 257°C to 174°C and make this peak elute in a completely different position.

A useful exercise is to ask students to optimize a separation, while providing a number of practical limitations. For example:

“I have a MS system and I need to optimize throughput to reduce cost per analysis.”

The limitation of the MS system is often the vacuum pump capacity, being approximately 2 mL/min. So it would be a very interesting exercise to optimize the analysis using a higher flow rate. Alternatively, you could explore using a smaller diameter or a shorter column to reduce runtime. One can even compare separations on different stationary phases and select the most suitable phase before doing the optimization of the GC parameters – everything can be modeled and visualized. Plus, all models are interactive – and they can be saved and revisited.

Beyond the solution

Of course, there are limitations to any modeling system. In ProEZGC, you can only model the components that are in the database, so you must always consider that there may be more selective phases available. Also, the program displays the components as Gaussian peaks, whereas in real life peaks may have tailing caused by the injector, transfer lines, ionization source or column. Similarly, the program assumes ideal injection, whereas real-life peaks may show overload due to sample composition or poor loadability of the column.

We have been presenting the capabilities of ProEZGC as a half-day workshop at several universities, and believe it will be a useful teaching tool for chromatographers worldwide.

Jaap de Zeeuw is International GC Specialist, Restek Corporation, Middelburg, The Netherlands.

You can register for ProEZGC at: http://www.restek.com/proezgc.