A new surface – the REDIchip – uses nanopost array (NAPA) technology and can identify traces of chemicals as low as 10-19 moles, according to its inventor, Akos Vertes, a professor at George Washington University, who has been working on the project for over seven years.

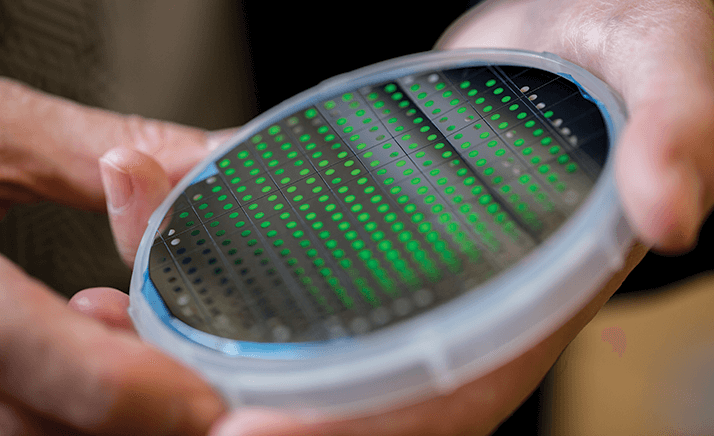

“Initially, we were experimenting with a silicon surface made by a laser process. Our idea was to take the silicon surface and use it for the production of ions. We had some success but there was no way we could get a wide enough range of geometries,” says Vertes. At that point, Vertes and his team turned to nanofabrication, which was able to produce nanopost structures with a much wider variety of geometries. The research team tuned the post diameters, post heights, and the periodicity of the posts, and found that the best for producing ions had a 150 nm diameter and a height of 1200 nm. However, the big breakthrough came when Vertes’ students laid down some yeast cells on the nanostructures (1). “To our great surprise, we got very rich mass spectra from our MALDI instrumentation from as few as 100 yeast cells. Even when we used one yeast cell we still got meaningful spectra. And that meant two things: one, the limit of the detection on the surface was exceedingly low; and two, we had a method that enabled us to directly interrogate micro-organisms without sample processing,” says Vertes. Resonance-enhanced desorption ionization – REDI – was born. Other studies confirmed the low limit of detection (2) but one big challenge remained – being able to manufacture the chips or, more specifically, the nanoposts economically in greater numbers; around 27 million posts are needed on each chip. Vertes says, “Producing posts one by one, which is how we started, is not a welcome proposition. Indeed, it was a dead end for commercialization. But Protea Biosciences – a long-standing partner of the university that licensed the technology – came up with a method that helped us to produce a large number of chips in parallel in a relatively short amount of time.” According to Vertes, there are many potential applications for the surface, including trace analysis in biomedical samples and detection of trace contaminants in the environment. “Today, people are also talking a lot about endocrine disruptors and their detection is another potential application,” Vertes adds. “Another class of applications will be imaging applications. We can take a tissue section and lay it over the surface of nanoposts to map the distribution of metabolites and lipids. It doesn’t take one molecular image, but as many molecular images as the number of peaks you have in the spectrum.” Even though the chip has recently been commercialized by Protea, Vertes doesn’t intend to wash his hands of the technology, and is currently working on the next generation. He wants to push the sensitivity even further and discover more applications, particularly in the biomedical field.

References

- B. N. Walker et al., “Metabolic Differences in Microbial Cell Populations Revealed by Nanophotonic Ionization,” Angew. Chem. Int. Ed., 52, 3650 (2013). B. N. Walker, J. A. Stolee and A. Vertes, “Nanophotonic Ionization for Ultratrace and Single-Cell Analysis by Mass Spectrometry,” Anal. Chem., 84, 7756 (2012).