Ever since I started working in chromatography, I’ve been intrigued by the creative combinations of technology and science that are used to solve complicated analytical challenges. However, I have never been much of a researcher; personally, I love designing new concepts and ideas, and finding unique solutions rather than doing the actual experimentation. To be honest, I sometimes felt like the odd-one-out, particularly during scientific conferences, but after a while I figured out my driving force: creativity.

Ever since this red thread became clear, I became even more fascinated, and started to read everything I could find about creativity and innovation. I took courses to broaden my scope and to try to discover the science of creativity. Today, I have the pleasure of applying my knowledge at work. And I want to share my vision and some of the techniques we apply at Interscience to stimulate and manage creativity and innovation. I call it “Lean Innovation Management” because it takes principles from creative thinking and transforms them in a smart and efficient way, so that they can be more easily grasped by typically ‘left-brain-dominant’ people – that is to say, logical, analytical, and objective thinkers – or scientists.

Lean Laboratory

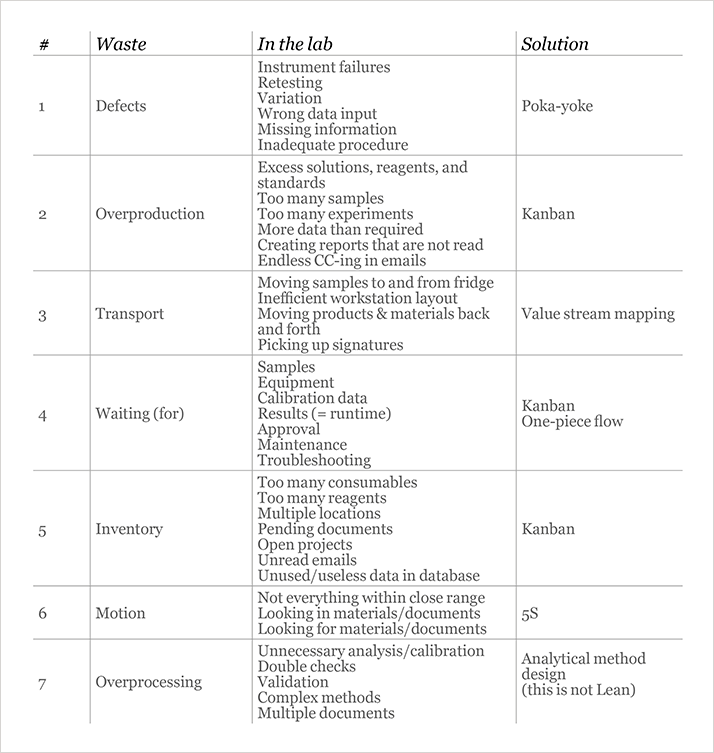

Lean philosophy stems from the Toyota Motor Corporation, where it was developed by Taiichi Ohno as an alternative to the rigid “high volumes, low margin” strategy applied by the large US car manufacturers of the 1950s. Back in those days, it wasn’t called Lean. It may have been referred to as flexible mass production, the Toyota Production System or simply “Toyotism”. The term Lean (coined by MIT’s John Krafcik) was popularized much later in a 1990 book called ‘The Machine That Changed the World’, by Jim Womack, Daniel Jones, and Daniel Roos (2). One of the core aspects of Lean lies in visually representing all steps of a procedure and subsequently determining the average turnaround time, process time and first-time-right percentage for each of them. By doing so, people become more aware of the complexity of the processes they are part of and learn to realize why things tend to go wrong. By applying Lean, you can often discover that in many cases errors are not caused by your annoying colleague, but as a dire consequence of an inappropriate procedure. In that respect, Lean can be considered a management technique that urges people to collaborate on designing the most efficient procedure. The technique of visualizing procedures is called value stream mapping (VSM). It identifies steps with little or no value – in other words: waste. Womack, Jones and Roos defined seven types of waste that could have a negative impact on the efficiency of a given process. These are: defects, overproduction, transport, waiting times, inventory, motion and overprocessing. Table 1 indicates how waste can be related to analytical laboratories. See "LeanTools" for tools that can be used to find a solution.The value of creativity – and the innovation that follows – is obvious. To become more creative, however, we need time to contemplate the world that surrounds us, so that our brain can almost subconsciously connect the dots. Unfortunately, time is a scarce resource these days. Are you aware, for example, that the amount of information that reaches us every day equals that reaching a 17th century Englishman during his entire life? News flashes, tweets, status updates, product announcements, application notes, targeted marketing and online education are continuously distracting our brain, making it very difficult to differentiate between valuable and useless information. Our new reality is defined in certain circles by the acronym VUCA; a world of increased ‘volatility, uncertainty, complexity and ambiguity’ of information. Nonetheless, the easy access to (sometimes new) knowledge is a prime driver for future growth, and so trying to escape it is not really an option. In my humble opinion, the best way to cope with this VUCA madness is to apply “Lean” philosophy (see, “Lean Laboratory”), which essentially removes all ‘wasted’ resources to focus only on the aspects that provide value.

Getting creative

Serendipity or ‘accidental discovery’ is the absolute epitome of innovation. Vaccination, penicillin and Viagra are some famous examples of serendipitous discoveries, but did you know that the splitless injection technique, stir bar sorptive extraction (SBSE) and selected ion flow tube MS (SIFT-MS) were also discovered by clever accident? Anyone working in research will have hopefully experienced their own ‘aha!’ moment – that funny feeling in your stomach when you know you’re on to something big. Instead of waiting for the unexpected to happen, wouldn’t it be nice to possess a formula that induces discovery? This formula exists. It all starts with, in sequence, the three Ps: philosophy, people and process (1).

Philosophy refers to company vision and strategy (and the resulting structure and resources to support them). The right philosophy allows innovation culture to drip down from the top to the bottom – and erupt back up again. An innovation manager or a chief innovation officer is an excellent facilitator in this regard. In addition, workplace organization, visual stimuli and offices that induce impromptu discussions are other factors that help creative thinking. But perhaps the most important signal to give employees is that they are allowed to fail. If not, they will never share their crazy new ideas. In terms of failure, Jørgen Knudstorp, the CEO of Lego, says it like this: “Blame is not for failure, but for failing to help or asking for help”. I recall Knauer’s managing director, Alexander Buenz, sharing similar thoughts in his In My View article in January 2014 (3): “It is important for everybody involved in [the] creative process to explore new fields – and, therefore, to take risks and fail. And while many companies claim to accept mistakes as part of their culture […] we actually demand that everybody takes ownership of at least one major mistake each year, which is cheerfully acknowledged in our annual appraisal meetings.”

Clearly, people are at the heart of the creative process and must be open to creative thinking in order for the magic to happen. But that’s much easier said than done and so it often proves to be an arduous task. Why? Well, creative thinking requires skills that are not really actively promoted (or assessed) in scientific education. As researchers, we are trained to work alone and to be problem-driven rather than solution-driven. Creative thinking, on the contrary, draws less upon logic and systemic reasoning, but more on imagination and intuition to explore the possibilities of “what could be”. This does not mean that a creative scientist has to forget everything. Absolutely not. Expert knowledge is helpful to distinguish between feasible and unfeasible ideas (note that I have not used ‘good’ and ‘bad’ ideas) – and that saves innovation teams a lot of valuable time, which is desirable and in full accordance with Lean philosophy. It’s very common for creative scientists to have a scope of interest that goes much further than the intimacy of their working domain. They are open to a variety of stimuli that can trigger new insights and creative connections. Let me be clear: becoming more creative is 100 percent a personal choice; it’s not a prerequisite reserved for artists and musicians. If you’re interested, I can recommend the book “Creative Confidence, Unleashing the Creative Potential within Us All” for further contemplation (4).

Lean can play an important role in the acceptance and induction of creativity and innovation in a laboratory environment. Firstly, because it compares very well to scientific thinking, it is really easy to master for ‘left-brainers’; for example, the ‘Five Why’s Procedure’ (see sidebar “Lean Tools,” opposite) very much resembles a root-cause analysis. Moreover, by choosing to optimize general laboratory processes first, people get acquainted with the basic principles of the technique, making the acceptance of “Lean Innovation” further down the road much easier. And let’s not forget that the recovery of previously wasted time can be applied immediately to think, work and act more creatively. A clear win-win.

In the final P of innovation – process – Lean tools can be applied to their full capacity. Of course, philosophy and people are equally important, but without a clear process of innovation, it’s virtually impossible to measure, analyze and improve the creative output of a team – or the net amount of new knowledge acquired. There is no definite process; not for manufacturing, not for analytical measurements and definitely not for innovation. Therefore, Lean thinking is all about learning and continuous improvement, which is achieved through the so-called ‘Build-Measure-Learn’ loop.

The cycle of creativity

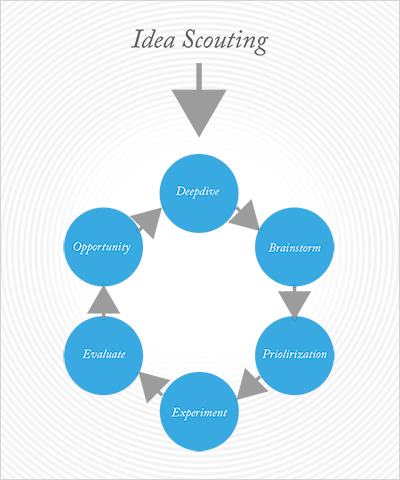

An excellent description of the creative thinking process was given by Katja Thoring and Roland Müller at the Conference on Engineering and Product Design Education in 2011 (5). The proposed model correlates well to the ‘Build-Measure-Learn’ loop of Lean from the point of view that once an idea is generated, it is prioritized, tested and evaluated for success. The main features of the creative cycle are depicted in Figure 1.

In keeping with the Lean-thinking theme, I believe it’s important to gather information continuously – even before an opportunity is presented. Remember that Lean is all about removing waste, so if you decide to start searching for ideas the moment a problem is presented, then a lot of valuable time will be lost. Crafting new ideas is not something that happens overnight or when someone asks a question. A creative spark ignites so much faster in a prepared mind. Start by doing a little bit of research every day, organize it, review it and apply it when necessary. I call this ‘idea scouting’ (see below); it’s a constant feed of interesting ideas that can flow into the creative cycle. Without this feed, it takes much more time to start the creativity cycle turning at full speed.

Lean Tools

Value stream mappingA technique to visualize procedures, which identifies steps with little or no value – in other words: waste. One-piece flow

Best explained with an example: assume a three-step procedure in which each step is carried out by a different person and takes one minute to complete. When the batch size is 10, the first sample reaches the end of the process after 21 min, the entire batch is finished after 30 min. When we reduce the batch size to one, it means that the first sample is ready to be analyzed, shipped – or whatever – after 3 min. The entire batch is ready after 12 min! The time gains are significant but sometimes less obvious because they seem counterintuitive. The effect of batch size on productivity becomes even more important when something goes wrong: detecting the error will take 21 min in a large batch compared with only 3 min in a one-piece batch. Moreover, in the small batch only three products are potentially affected compared with 30 in the large batch. Five why’s procedure

An iterative questioning technique used to determine the root cause of a problem. (Five is the number of iterations that are usually required to determine the cause.) 5S

A method that describes how to organize a clean and efficient workplace. It involves a sustained hierarchical organization of all the tools and products that are needed to get a job done. Kanban

A system to control the logistical chain. The heart is formed by the Kanban card, which signals depletion of a product, triggering its replenishment. By means of Kanban, demand for new product is pulled through the production chain rather than pushed, giving rise to zero overproduction and stock. Poka-yoke

Any mechanism that helps an operator to avoid making mistakes. For example, the smart construction of an MS source that means after cleaning, there is only one way to reinstall it.

Idea scouting

My method for scouting ideas centers on screening VUCA, keeping interesting information and sharing it with other people, both inside and outside the organization. I use “Google Alerts” to identify interesting articles or blogs to follow. For scientific publications, I use “Research Highlights”, which displays new articles that contain predefined keywords or authors. To increase the chance for serendipitous discovery, I use these tools predominantly to follow topics that do not immediately relate to gas chromatography (my main interest). Interesting blogs and journal announcements are organized in Feedly (feedly.com), which tracks all my RSS feeds. Whenever I come across something interesting, I forward it to “Evernote”, where it is organized in folders and tagged for easy recovery. Finally, I prepare a monthly ‘tech letter’, which is shared across the company. If you consistently apply this approach, it’s surprising how many new ideas start to sprout in your mind – often at moments when you least expect it (I have a waterproof notepad installed in my shower just in case).

Opportunity definition

Lean creativity is opportunity-driven. That is to say, a new cycle doesn’t start, if no opportunity has been identified. It avoids wasting valuable time whenever an unapparent non-idea travels through the creativity cycle. I call it ‘idea pull strategy’, which is similar to the pull strategy in Lean manufacturing and means that the creativity cycle begins only when a clear question has been articulated by an end-user or other stakeholder. Let’s assume that every single idea is developed and evaluated, even if you didn’t know that there was any value to the end-user; it would cost time and money, and lead to frustration in your team. Lean processes are driven by pull strategy, which means that a new process is only started once an order has been placed. It avoids overproduction and stock, which are two of the seven wastes mentioned in Lean. Since the end-user and not the creative scientist should determine what must be developed, close customer collaboration or co-creation is very important. Pulling ideas through the innovation cycle is good protection against ‘freewheeling’, which is the risk of researchers working on something that might look promising but has no real value.Once an opportunity has been defined, it is time to rummage through your idea basket. Does it contain anything that could be of any use for the opportunity at hand? By using your experience and expertise, you can quickly assess the value of potentially interesting ideas. Contrary to outside-the-box thinking, people tend to be more creative when they focus on the internal aspects of a situation or problem and when they constrain their options rather than broaden them. By reframing and clarifying the opportunity and challenging the assumptions that surround it, creative output becomes more relevant than playing word-association games or talking about grand abstractions. Deep diving is a solitary action and takes time. The first ideas are certainly not the most creative ones. Be persistent and explore all options. Professional Internet surfing can come in handy:

- Use Google Advanced

- Search within a site for more relevant information

- Use the Internet archive (https://archive.org/) to find sites that are no longer active

- Search for xls files

- Apply Whois (http://www.whois.com/) or try a patent search (http://www.patentinspiration.com/) to find out what your competitors are up to.

Brainstorming is a team effort. The success of a brainstorm, however, largely depends on the quality of its moderator. If people feel uncomfortable, they hesitate to present their ideas and the brainstorm becomes highly frustrating for all attendees. The same applies when the team is packed with dominant alpha males. Nonetheless, a brainstorm session is a powerful tool to create a lot of new ideas. In that respect, a multidisciplinary set-up, with people from diverse industries, cultures, and departments, can lead to radical, invigorating collaboration. Imagine what new interactions might occur in a biology team by adding non-biology disciplines. Serendipity almost guaranteed! A creative way of dealing with brainstorming was proposed by Terry Barnhart when he was working at Pfizer. He applied a procedure similar to Lean’s value stream mapping to gather and organize the questions that need to be resolved to address a particular scientific challenge. He called this procedure critical question mapping (CQM). It is described in detail in his book, “Creating a Lean R&D System” (6).

Use the brainstorm session to generate as many ideas as possible. Afterwards, give the team time to reflect on the ideas and set a top 10 (or a top 100, if you’ve been very productive). Score each idea to introduce some priority listing. It is not necessary to de-select valuable ideas from the list, Lean provides an excellent tool to deal with large amounts of data: one-piece flow. One-piece flow is a Lean technique that proposes to prepare each product individually rather than in a large-size batch. By working this way, turnaround times are reduced significantly and the impact of errors on the process is less significant because only ‘one piece’ is involved rather than a batch of pieces (see sidebar “Lean Tools” for an example).

The goal of the experimental phase is to assess the viability of an idea, not to provide full experimental validation. Validation takes a lot of time and you’re never sure whether the outcome will prove to be in accordance with your initial assumptions. Isn’t that the paradox of scientific research? Let’s assume, for example, that you have identified a new material to selectively extract contaminants from food. The goal of the experimental phase could be to design several configurations of the material both physically and chemically. Under Lean conditions, a ‘minimum viable experiment’ is designed that allows you to select the most viable approach. In accordance with the concept of one-piece flow, each configuration is tested against a minimal set of quality criteria; for example, recovery, selectivity, inertness and so on.

Each experiment is evaluated individually. Based on the outcome of this evaluation, you can decide whether or not that particular configuration is feasible. Valuable ideas can be assessed in greater detail in a complete validation cycle, while less promising ideas are set aside for reconsideration (pivot or persevere?). Irrespective of the outcome of an experiment, it is always characterized by the acquisition of new knowledge.

Idea management, creativity and innovation have been buzzwords for quite some time now. Scientists, researchers and their managers need to be aware of their importance. However, in order to be successful, a particular strategy needs to be applied – and that strategy needs to be tweaked to suit our particular intellectual framework. We have adopted what I believe to be a unique tactic that merges left-brain process thinking and efficiency with right-brain creativity. The application of Lean thinking for process optimization has been applied quite extensively in drug discovery. All large pharmaceutical companies have applied the techniques mentioned here to identify and remove wasted time and recover it for creative thinking. What they haven’t done, however, is to consider creative thinking as a process in itself and that’s a missed opportunity.

Joeri Vercammen is managing expert at Interscience, Louvain-la-Neuve, Belgium.

References

- J. Dyer, H.Gregersen and C. M. Christensen, “The Innovator’s DNA” (Harvard Business Review Press, 2011). J. P. Womack, D. T. Jones, and D. Roos, “The Machine That Changed the World” (Scribner Book Company, 1990). A. Buenz, “Breaking the Rules” (theanalyticalscientist.com/issues/0114/breaking-the-rules/ 2014). D. Kelley and T. Kelley, “Creative Confidence: Unleashing the Creative Potential Within Us All” (William Collins, 2013). K. Thoring and R. M. Müller, “Understanding Design Thinking: A Process Model Based on Method Engineering”, presented at the International Conference on Engineering and Product Design Education, City University, London, UK, September 2011. T. M. Barnhart, “Creating a Lean R&D System: Lean Principles and Approaches for Pharmaceutical and Research-Based Organizations”, (Productivity Press, 2012).