We caught up with Christopher Ball, research scientist in the ElectroScience Laboratory at The Ohio State University (OSU), USA – whose team is developing miniature NIR sensors for field use in the food and agriculture industries – to discuss the future of miniaturized spectroscopy.

What are the main recent developments in miniaturized spectroscopy?

The most exciting developments currently involve the growing availability of high fidelity, low cost, miniaturized spectrometers that cover the near infrared (NIR) spectrum (780–2500 nm). Over the past 10 years or so, the rapid development of silicon-based complementary metal-oxide semiconductor (CMOS) components have led to development of smaller, lower-cost devices. However, for accurate measurement of specific compounds, longer wavelengths are required.

Now, longer wavelength (1300–2500 nm) NIR spectrometers based on extended Indium gallium arsenide (InGaAs) detectors have started to become available in miniaturized packages. These spectrometers typically leverage micro-electromechanical systems (MEMS) to develop extremely small Fourier transform spectrometers – at the centimeter scale in terms of dimensions. These commercially available spectrometers are enabling the development of handheld sensor technologies that can be used in the field, with performance competitive with laboratory-scale instruments.

How are advances in data analysis making a difference in the development of handheld spectrometers?

In step with developments in spectrometer hardware, advances in data analysis are also necessary to enable high fidelity, handheld spectroscopic sensor systems. Traditional multivariate methods, such as partial least squares regression (PLSR), enable real-time spectral analysis of raw data generated by miniaturized spectrometers automatically with little input from a user. Though PLSR and similar algorithms are great for relatively simple mixtures of known compounds in a sample, more complex mixtures, as well as characterization of unknown mixtures, require deeper levels of analysis that can benefit from emerging artificial intelligence (AI) techniques. We have only scratched the surface of AI analysis of spectral data, and I expect an explosion of new methods over the next several years.

Tell me about the sensor system your team developed

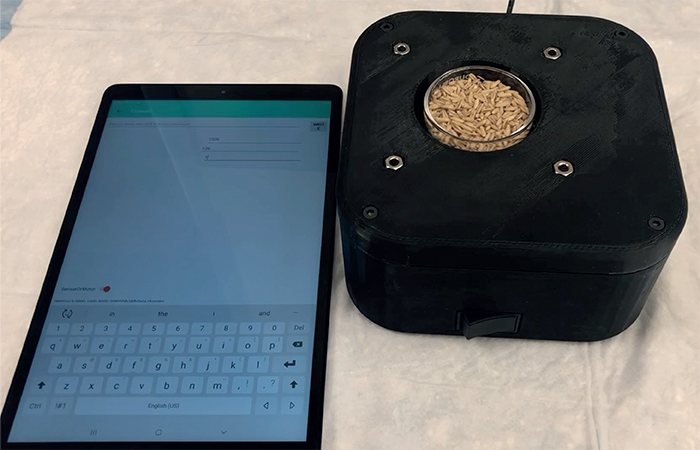

My colleague, Luis Rodriguez-Saona, and I developed a handheld sensor at The Ohio State University that is based on a commercial, miniature NIR spectrometer (NeoSpectra Micro, Si-Ware Systems Ltd.) operating over a range of 1350–2560 nm.

Our sensor primarily targets samples in the food and agriculture domain, such as soybeans, oats, citrus, and hemp. We developed a rotating sample interface to improve the quality of measured data and to enable measurements of intact seeds or groats. By rotating the sample, the spectrometer can measure heterogeneous structures and multiple view angles, which are then spatially averaged to produce a composite spectrum for the sample material.

In addition, we developed an app-based sensor control and data analysis tool that automatically analyzes samples at the push of a button, such that a completely untrained user can learn to take laboratory-quality data with minimal training. The sensor can interrogate a sample and produce results in seconds. Upon completion of a measurement, the spectral data are transmitted via Bluetooth to a tablet or smartphone running our custom app.

We involved OSU’s Center for Design and Manufacturing Excellence (CDME) when designing and assembling the sensor hardware and developing the associated app. CDME worked with a team of talented undergraduate engineering students to design the power, mechanical, data communication, thermal management, and sample rotation subsystems. The team worked through several designs over time, each incrementally improving upon the last and solving design challenges, like the rotation motor.

You mentioned hemp – what challenges are there in the cannabis field that this technology could overcome?

One of the big issues with growing hemp is ensuring that the tetrahydrocannabinol (THC) content in plants is less than the federally mandated level of 0.3 percent. If plants are found to exceed this threshold, the entire crop may be lost, which is a great expense for a grower.

Our sensor can be used on the farm, as an adjunct to mandated laboratory sampling, to inform growers that THC content is approaching the 0.3 percent limit and that the crop should be harvested. In addition, our sensor can measure other cannabinoids, such as cannabidiol (CDB), for health and medical products, and also protein and amino acids for hemp seed-based food products.

What are the most promising applications of this technology?

Our work focuses on the characterization of food and agricultural products, and we have demonstrated that our sensor can provide valuable and timely information to growers, commodity buyers, food producers, researchers, food sellers, and regulators.

Currently, products are analyzed by sending samples to a laboratory, which can take weeks and cost thousands of dollars. Our system enables measurements in near-real time, with no consumables, at a one time sensor acquisition cost that likely would be less than $5,000 when productized. The sensor allows farmers to make informed decisions about harvest timing, the quality of their product, and likely economic value of their crop all at the farm. A food producer could use the sensor to assess the quality of incoming feedstocks for sorting into various production lines based on nutritional content. A regulator could assess the accuracy of the nutritional label of a food product.

Are there any limitations with this technology?

There are still a variety of challenges that can be overcome to produce even better sensors based on miniaturized spectrometers. We have ideas for dynamic illumination schemes that would eliminate the need for rotating stages, and thus eliminating moving parts.

We also have ideas for incorporating more complex AI into our data analysis methods to expand the types of measurements we can perform. Finally, there is always economic pressure to make sensors smaller, less expensive, less power hungry, and so on. And there are a variety of engineering paths we can take to produce smaller, more efficient devices…

Overall, how would you characterize the potential of small spectroscopic sensors?

The sky is the limit for miniaturized spectroscopic sensors. Though we tend to focus on food and agricultural applications, there are many other opportunities in pharmaceuticals, industrial materials, manufacturing processes, defense and security, healthcare, space-grown foods, and more. Each application has unique needs, and all can benefit from continuing research and development on small sensor technologies.