There is an unmet need for on-line elemental analysis of dissolved inorganic species in several areas of industrial process control and environmental monitoring. None of the known lab-based methods have emerged as workable solutions for routine on-line measurement of dissolved species. However, solution-cathode glow discharge (SCGD) is poised to upset the status quo. SCGD is compellingly simple: its capabilities for elemental analysis of aqueous solutions rivals inductively coupled plasma (ICP) – the atomic spectroscopy king – with lower power consumption and without plasma gas consumption, active cooling, and short-term drift.

There has been sustained academic interest in SCGD since its introduction by Cserfalvi and Mezei in 1993. A turning point in the development of SCGD occurred in 2007 when Michael Webb reduced the width of the plasma while maintaining plasma power levels. The resulting increase in power density greatly improved the sensitivity and robustness of the technique. Other researchers have attempted to improve the sensitivity through matrix modification (addition of low molecular weight acids and surfactants), pulse power modulation, and magnetic boosting.

InnoTech Alberta has contributed to the development of SCGD by making physical modifications that boost performance. Prototype iterations at InnoTech Alberta have focused on designing an optimal porous wick between the grounding electrode and the base of the plasma. This wick stabilizes the DC electrical glow discharge circuit and results in reduced emission noise at optimal low flow rates. Also, a self-purging design purges atmospheric gasses out of the plasma cell, which removes interfering molecular nitrogen emission. This substantially reduces background emission, improving signal-to-background levels.

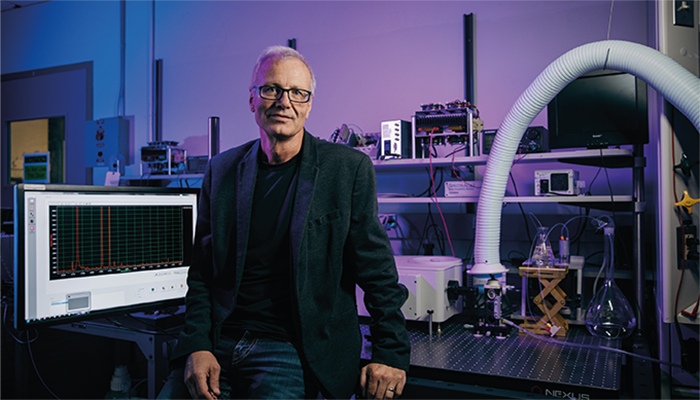

Stuart Schroeder in prototype development lab

Other researchers have used compact and low-resolution spectrometers coupled with SCGD; however, our work reveals that optimal performance is achieved when using a high-resolution spectrometer that acquires the full height of the plasma. Nevertheless, the search for the ideal spectrometer to interface with SCGD is ongoing. Continued research will lead to informed operational decisions on matrix management protocols and long-term drift affecting calibration frequency.

Improvements to SCGD will continue to be made, but the basics of operational principles have been established and this novel plasma is ready for commercialization – for which there is an appetite, driven by the industrial need for process optimization in real time. Initial success here could be the catalyst for widespread adoption of SCGD.

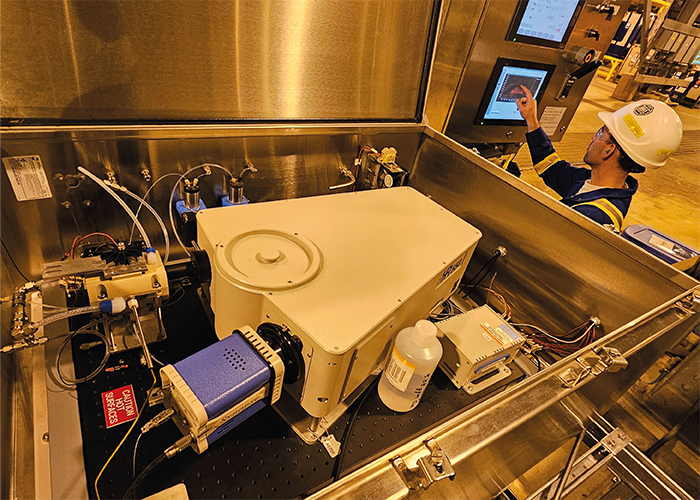

Stuart Schroeder flipping the switch from standby to run mode for 1st time

Our industrial funding partners (Imperial Oil Resources Limited and Canadian Natural Resources Limited) represent two in-situ oil sands companies in Alberta. Successful implementation of SCGD technology, with our oil sands partners, will lead to operating cost savings at in-situ oil sands central processing facilities. Currently, in-situ oil sands facilities rely heavily on infrequent manual sampling and laboratory water analysis for process control. On-line elemental monitoring with SCGD will allow operations to run closer to process targets, which will lead to operating cost savings via reduced steam generator fouling, optimized chemical dosage, and an increase in average steam quality. An increase in steam quality will also lead to a reduction in greenhouse gas emissions intensity. Our current project is a pilot of an on-line SCGD analyzer prototype at an operating in-situ oil sands facility in Alberta. The pilot is the third and last phase of a multiyear collaboration and is conceivably the world’s first use of a plasma spectrochemical emission source for on-line industrial process optimization.

Several markets exist for a fully developed SCGD platform technology. Today, however, there is a lack of commercially available instrumental techniques capable of simultaneous multi-element analysis in real time for on-line analysis. SCGD is positioned to fill this technology vacancy and represents disruptive technology for on-line industrial process control, environmental monitoring, and effluent discharge monitoring from both industrial and municipal sources. Additionally, the technology offers a simpler, more portable, and more stable alternative to the mature lab-based technique, ICP.

In the prophetic words of Gary Horlick, pioneering researcher in atomic spectrometry, “ICP will be replaced, sometimes you just have to believe.” Indeed, I believe SCGD is poised to challenge ICP as the sole dominant technique of atomic spectrometry.

Wade Hagman with SCGD instrumentation