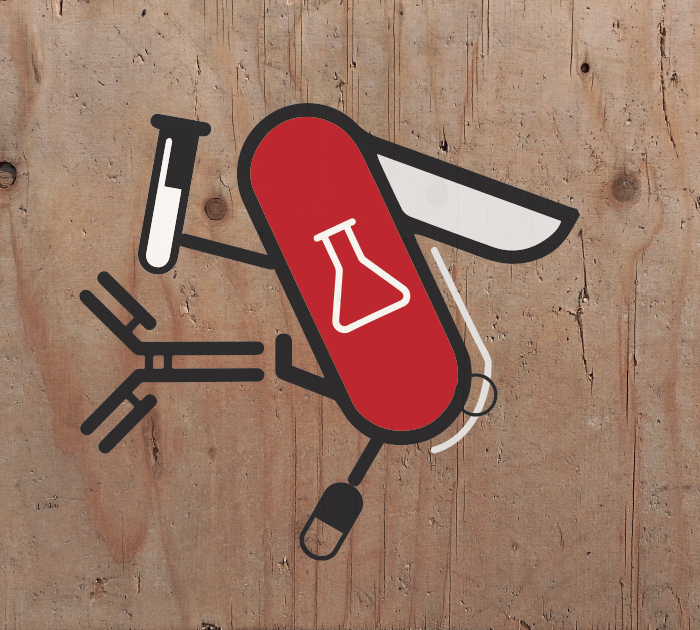

Quick and straightforward, size-exclusion chromatography (SEC) has become a Swiss Army knife for the analysis of protein aggregates. It is a “mild” technique that usually preserves biological activity and structural integrity – and could almost be considered a platform technology. Coupling of SEC with various advanced detectors, such as a mass spectrometry, light scattering or surface plasmon resonance, makes it a versatile tool for numerous applications beyond aggregates. With new biopharmaceutical formats in the pipeline – bispecific monoclonal antibodies, antibody–drug conjugates and virus-like particles, for example – rapid and thorough characterization will be even more important. Timelines in analytical laboratories are increasingly tough – on the other hand, there is a strong drive to explore and understand biologics in more detail. In separation science, this means higher resolution and plate counts in shorter analysis times.

Small is beautiful

Over the past 30 years, miniaturization has been the key trend both in stationary phases and instrumentation. Smaller particles provide better separation performance, so we can either shorten the required separation path lengths, or provide better performance at the same path length. The use of smaller particles also pushed the optimum column dimensions towards smaller values, with the welcome side-effect of saving solvent. When it comes to biopharmaceuticals, HPLC and UHPLC cannot be as strictly segregated as in other disciplines. In this setting, UHPLC is defined as “ultra-high performance LC” rather than the more common definition – “ultra-high pressure LC”. Especially in SEC, the small (2 μm) particles of UHPLC do increase the pressure – but rarely exceed the pressure limits of modern HPLC. Any higher, and the resulting frictional heating and shear forces would damage the macromolecules and lead to artefacts. Instead, bio-UHPLC is focused on optimization of valves, capillaries and flow cells to decrease dead volumes and subsequent Eddy diffusion – which also holds true for conventional HPLC columns.Upgrading biopharma’s Swiss Army knife

UHPLC is already a standard technology in the analysis of small-molecule drugs so it is no surprise that biopharmaceutical manufacturers are now looking to follow suit. Our TSKgel 3000SWXL column is a standard tool for QC aggregate analysis by SE-HPLC, and we noticed an increasing demand for a 2 µm-particle column that enables easy method transfer to UHPLC.There were many challenges in developing such a column. The minimum particle size for HPLC is believed to be 1 µm (1), so at 2 μm we are skirting the edge of what is possible – and that’s never easy going. But chromatographers really appreciate the benefits in terms of speed and resolution. Of course, UHPLC is not a magic bullet. Coupling a SE-UHPLC column to a non-optimized system with dead volumes is an unhappy marriage. The smaller internal diameters result in lower volumetric flow rates, which leave more room for undesirable Eddy diffusion. In some cases, this may result in worse separation performance than with a conventional SE-HPLC column, so it’s important to consider the system as a whole. Thorough characterization of every new drug is crucial for patient safety – and complex next-generation biopharmaceuticals present a challenge. I expect to see diversification of columns – columns capable of delivering high performance for fundamental research and columns dedicated to rapid in-process control and drug release. With regard to instrumentation, the use of LC-MS and other hyphenated techniques will continue to grow.

Senior scientist Xianwen (Susan) Chen and her colleagues in the process analytical group at Boehringer Ingelheim Fremont, Inc. are making the switch from HPLC to UHPLC for some routine SEC analyses. We caught up with Chen to find out more. What is the focus of your work? It’s always been my goal to work in pharmaceuticals – and to help deliver drugs to patients. My PhD was on drug screening and afterwards I joined the pharmaceutical industry as a development scientist. I’ve been at Boehringer Ingelheim for two years, working in the process analytical group. We support process transfer, optimization and development, starting from the cell culture through purification, right up to formulation. We develop assays to test product quality; for example, if our purification group need to optimize their column conditions, they will try different buffers and processes, and send samples to us to test the product quality – aggregate level, charge variance, fragmentation, and so on – and we will provide feedback on the process that gives the best results. What challenges do you face? The samples we deal with are varied and often arrive in large numbers – if we’re working with a team doing a Design of Experiments project, hundreds of samples might be submitted at once. So it’s crucial that we use reliable instrumentation that allows us to carry out very robust, high-throughput assays. How do you use size-exclusion chromatography? SEC is one of the essential assays we run every day, particularly for monoclonal antibodies. It tells you aggregate and degradation levels of the product, which is absolutely key information that is required by the FDA. There is a safety concern, in that aggregates could trigger an immune response that could render the drug ineffective or even cause adverse events. How has SEC technology advanced in recent years? The main advance in the past decade has been the arrival of UHPLC with sub-2 μm-particle columns. The first UHPLC column for SEC was released in 2010; now, a number of new columns are coming onto the market, such as the Tosoh TSKgel UP-SW3000. With existing UHPLC columns, we’ve noticed lot-to-lot variation and a tendency to lose resolution when analyzing low-molecular-weight species. To combat those problems, we had to spend a lot of time troubleshooting, trying different cleaning solutions to get the resolution back. So when the new sub-2 μm column was released from Tosoh, we were happy to try it out. In a poster presented at the HPLC 2016 conference, we showed that the column is robust, with minimal lot-to-lot variation. Is UHPLC the future for SEC? UHPLC brings many benefits – assays run faster and with higher resolution. Over time, I think it will replace some of the older HPLC assays, which have been around for 10–20 years. Many pharmaceutical companies are currently in the evaluation stage, deciding whether to switch. Changing assays can be hard work, especially for commercial drugs, and you want to make sure the new technology lives up to its promise. I think the two technologies will be used in parallel for a long time to come.

References

- I Halász et al., “Ultimate limits in high-pressure liquid chromatography” J Chromatogr A, 112, 37–60 (1975). Available at: http://bit.ly/2p4pVfh. Accessed May 9, 2017.