February 29, 2020 (11 days before the WHO’s formal declaration of a pandemic), McCormick Place Convention Center, Chicago

After additional soldering, last minute UI programming, and general wrangling on an Airbnb kitchen table until 3am the night before, we rolled into the Pittcon exhibition hall with the functional insides of something wonderful. We were left with just one seemingly small task to perform: securing the stunning but somehow ill-fitting housing. Neither firm pressure nor brute force (a hammer was involved) resolved the issue. We had been working 18-hour days for 45 days straight, tackling all manner of serious challenges along the way; we would not be foiled by this final hurdle. We erected a makeshift barrier to hide our quickly hatching plan – and then started cutting away at the metal chassis of the instrument with a Dremel [other rotary tools are available]. The high-pitched squealing – and possibly sparks – undoubtedly raised eyebrows...

At 8am, prior to Pittcon opening, we all breathed a sigh of relief. The booth was spotless, our shiny innovation was on display. “That just happened,” I sighed. Exum’s Massbox – the world’s first commercial laser ablation laser ionization time of flight mass spectrometer (LALI-TOF-MS) instrument – was out in the wild.

My time at the MagLab and grad school (see “The Man in the Machine” for the long version) provided me with the opportunity to work with many different instruments – including every MS system you can think of. And they all had one thing in common – a bad user experience. I think my friend (and now head of applications at Exum) John Putman said it best: “I’m no longer intimidated by the hardware – but, man alive, the software! One wrong click of a button and I can put this million-dollar machine out of commission for months…” I felt the same way. I was also frustrated by how difficult it was to quantify a sample. Not only do you have to be a good analytical chemist to get the right data (find a good signal, turn the right knobs in the right order, stand on one foot, do a spin, finally get the peak you wanted…), but you also have to be a master mathematician to make the raw data mean something. The data processing often seems archaic – made all the more obvious when you pull out of your pocket what seems like a supercomputer in comparison.

Why does MS so often feel like a 1980s or ‘90s experience compared with our smartphones? Well, one answer (other than instrument companies typically not having the budget of Google or Apple) is that the instruments are often built on 1980s or ‘90s foundations. It’s a “tech debt” issue; virtual machines running on top of more virtual machines to enable the software to talk to an FPGA chip that was programmed in 1991… In other words, without starting from scratch, redesigning (or simplifying) the user experience is complex.

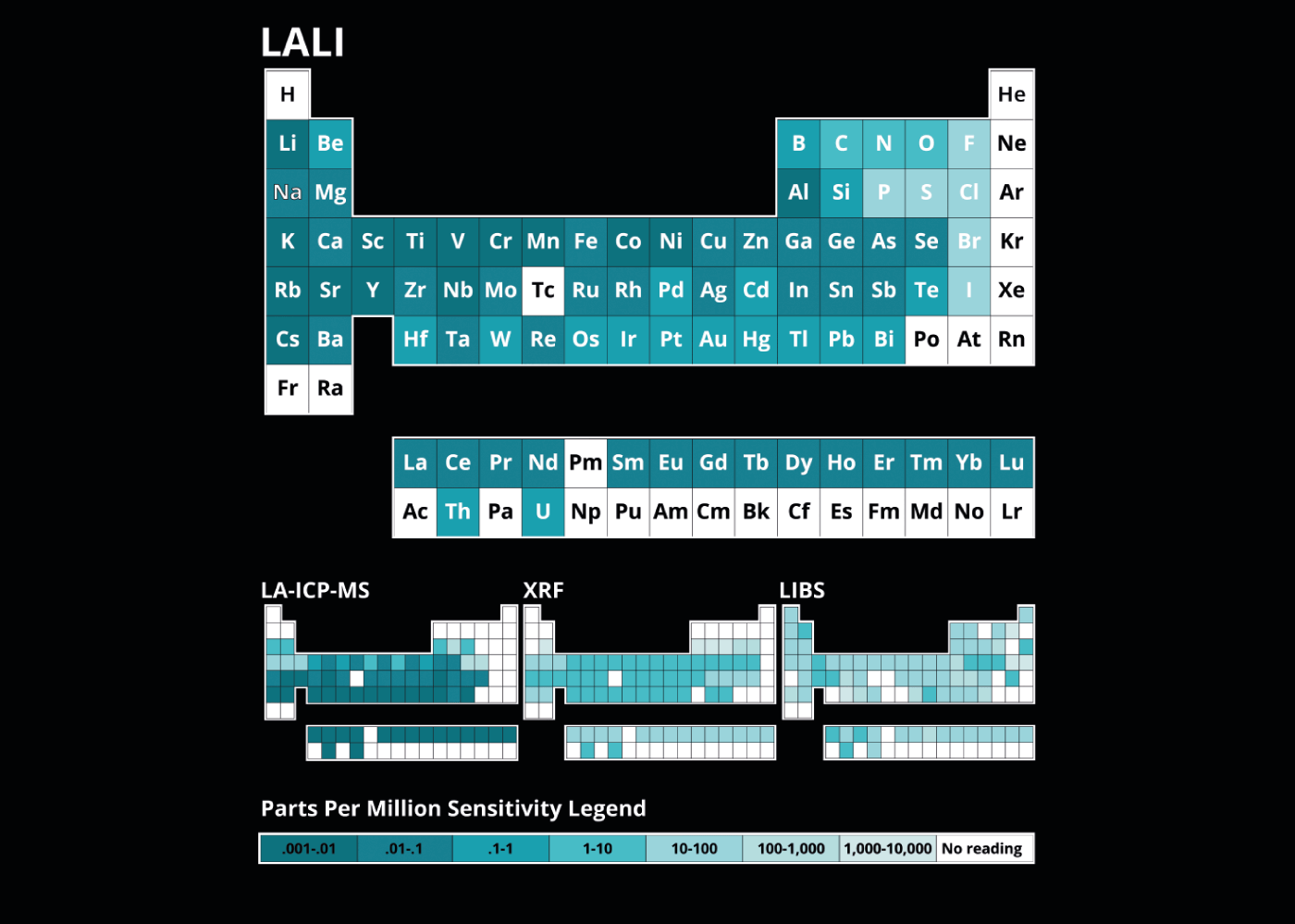

The Massbox is a laser ablation laser ionization time of flight mass spectrometer (LALI-TOF-MS) that can be used to analyze any solid material. Your sample could be a rock, a pharmaceutical pill, a cannabis sample, or an apple – if it’s a solid or pseudo-solid, the Massbox can determine both the inorganic and organic compounds. Notably, the dynamic range is such that we can determine both the major elements but also the trace elements down to concentrations of parts per billion (see Figure 2).

Let’s use a rock as an example (because rocks are close to my heart). You place your rock (sample) into the Massbox, which first takes an image. The image of the rock is presented on the touchscreen, where you are able to select either individual sample spots or run a full map of the whole sample. For every spot, the first laser hits the sample and ablates material to form an initial plasma of excited ions – so far, this will be familiar to users of laser induced breakdown spectroscopy (LIBS) or laser ionization MS (LIMS) – but we don’t care about these initial ions; we’re interested in the neutral particles that are now floating above the sample surface (like a miniature version of the dust cloud that would result from hitting the rock with a hammer...). With exact timing, the Massbox hits those neutral particles with a second laser, which allows for more “normalizable” ionization of the sample.

What do I mean by more normalizable? The ions formed in the initial plasma – as used in LIBS or LIMS – are matrix or chemically dependent; ionization favors those ions that are more easily formed – potassium or sodium, for example – rather than those that are more difficult to ionize, such as silica. In other words, the ratio of elements in the sample is not reflected by the ratio of ions in the resulting plasma, which makes quantification complex at best. But the neutral particle cloud generation is much less chemically dependent, which means that the ions generated by the second laser are much less prone to matrix effects when the laser reaches a “saturation” of energy in the cloud.

Finally, the particle cloud ions are analyzed by TOF-MS in the same way that many MS users will be familiar with.

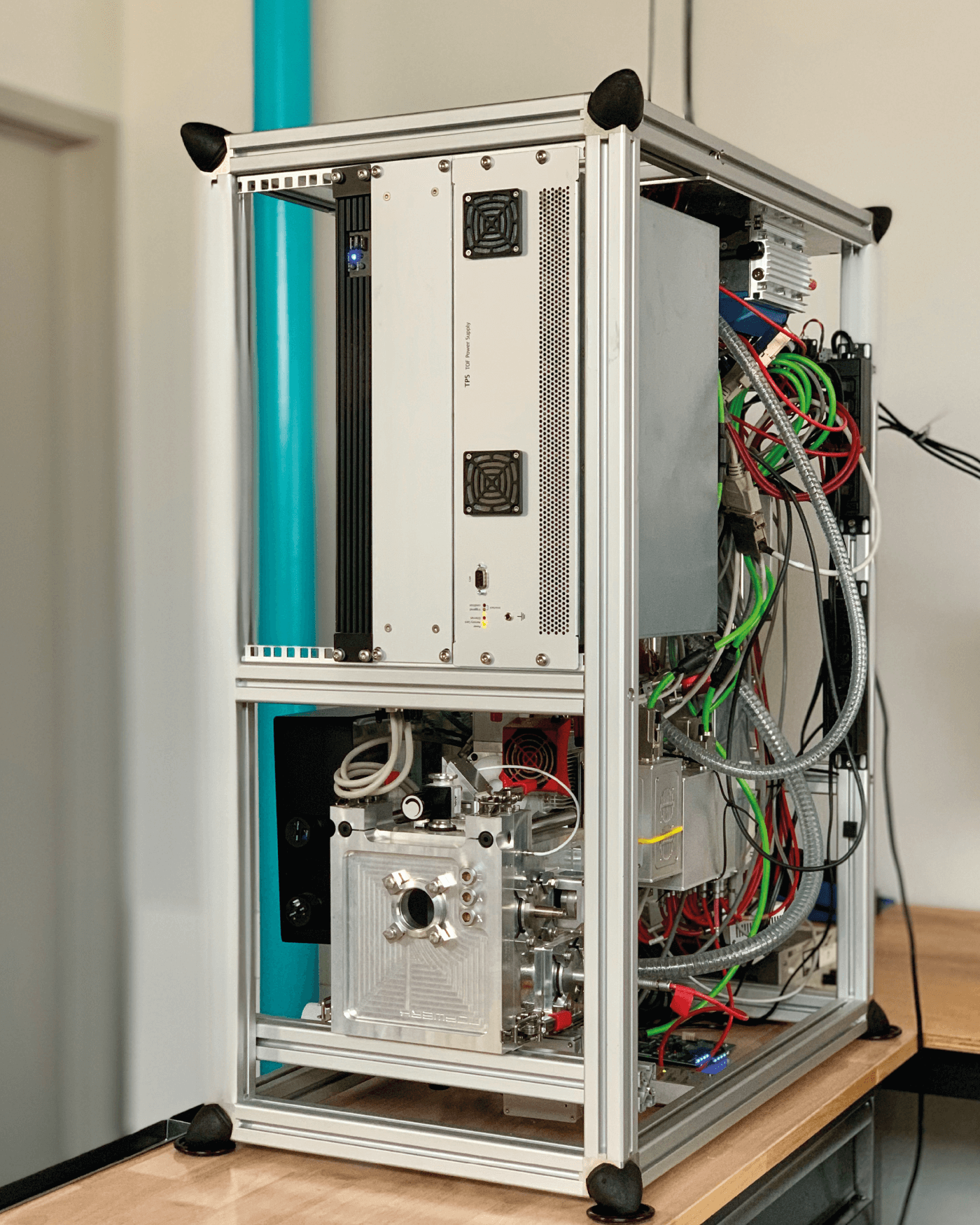

Perhaps most surprisingly, all of these laser blasts, microexplosions, particle clouds, and MS analyses occur in a desktop-sized, self-contained instrument. Please feel free to check out our website for an animation on how the Massbox works: www.exuminstruments.com

The whole ethos of Exum is driven by my desire for a completely different user experience, both from a hardware and software perspective. I think of our efforts as “hardware enabled software” – and that’s quite a different design and development philosophy compared with the big players. We must start with robust/stable technology under the hood, so the software can do its predefined job. I was aiming for a “just press go” or “science simplified” experience. It made complete sense to me to develop something that automatically performs the computational tasks I used to do manually – especially when I realized that, in the world of algorithms, we’re in a pretty easy-to-solve space. Of course, few analytical chemists like a “black box,” so if you want to dive into the details, you can.

The laser system we had started developing in our heads appeared to offer the prerequisite robustness – or linearity – to enable smarter software. In theory, we realized we could sidestep the complexity (and potential failure points) that would take us away from the “clean” software of my dreams. I guess the magic of the Massbox perhaps stems from the freedom to start with a fresh concept – where hardware and aspirational software could be considered simultaneously – one determining the needs and leaning on the strengths of the other.

But how did we arrive at our hardware innovation – LALI? Well, frustration got the better of me again. I needed to know the chlorine and iron content on Mars for my thesis, and the data from the Curiosity Rover was not making life easy. They’d basically sent an uncalibrated instrument up there without thinking about the need to quantify at a later stage.

Over a couple of beers with friends, we started discussing how we would design “a better instrument for Mars 2020.” It had to be laser-based MS, and so we started listing all the problems with LIBS and LIMS, dug into the literature and began to understand how neutral particles fit into the picture. Our first concept was based on tunable-laser resonance ionization, but that got way too complicated way too quickly. Back to the brainstorming.

I decided to discuss the concept with Munir Humayun at the MagLab, who asked, “Why not try a second laser?” I did another deep dive into the literature and got excited. We had a novel idea with real promise – and it seemed like a good PhD thesis. Given NASA’s passion to find life on Mars, I figured that we should aim target organics and inorganics – so the ablation laser must work in both infrared and UV. As we thought about the potential, we borrowed ideas from here and there, gradually building Frankenstein's concept.

Over time, I was also coming to a realization: I like experimenting and building things. But I hate writing and I hate politics. I was not cut out for the clawing, crawling journey to the top (I had plenty of that when rock climbing). I’d read a few books about entrepreneurship – and it really appealed to me. And I also saw a clear gap and a real opportunity. I figured it was the right idea and it seemed like the right time; my girlfriend was open to the almost certain lack of income that would come with the territory.

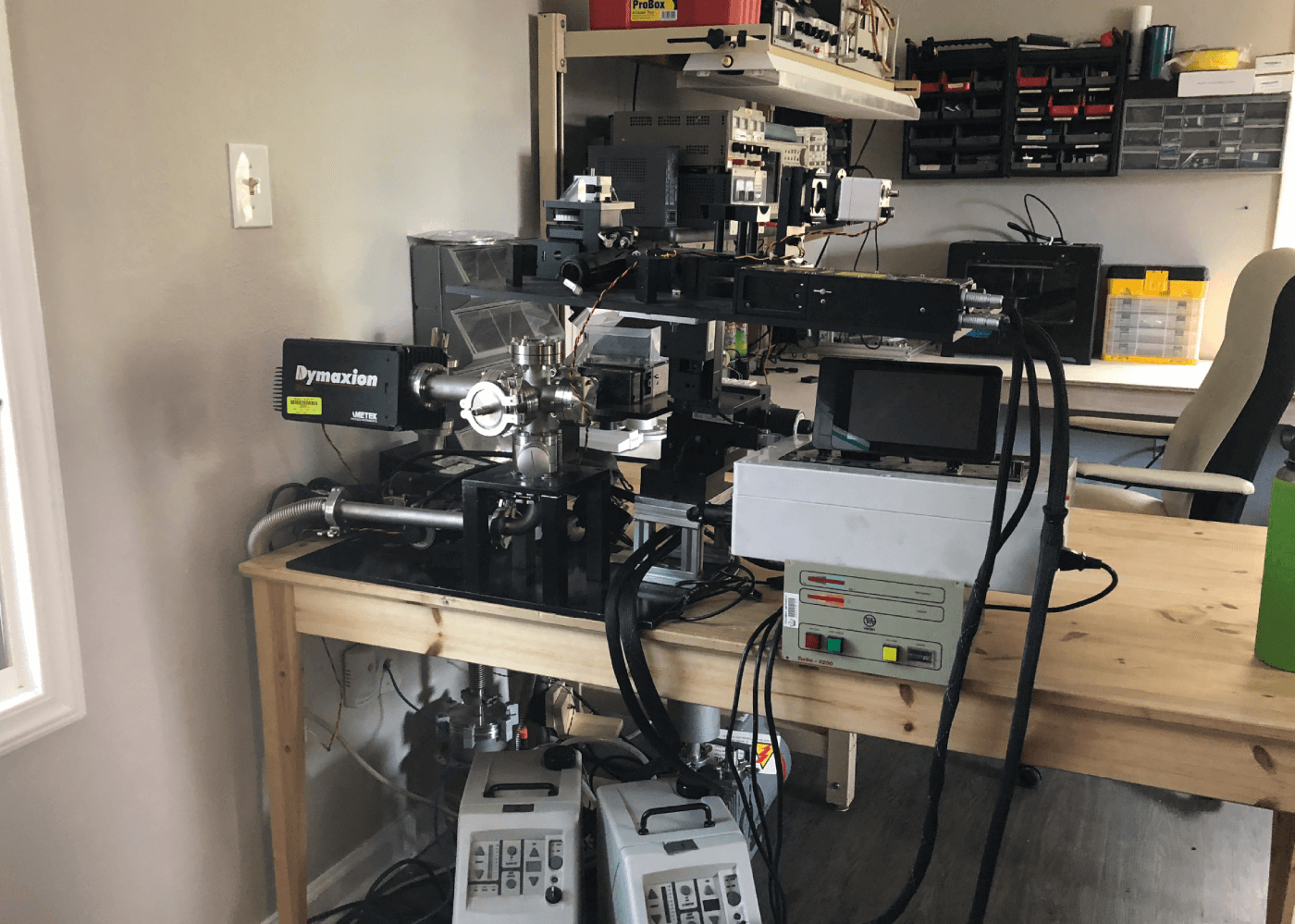

So I went for it and quit my PhD (settling for a Masters). Then, the scouring of government auctions commenced; the co-founders and I picked up all sorts of vacuum parts and boxes of fittings and flanges for a couple hundred dollars when they should have cost us tens of thousands. We also emailed everyone we knew in every lab we could think of: “Do you have a turbo pump laying around?” ... “Do you have a spare laser?” I can’t go into too many details, but we received some exceptional donations (and there are some pretty expensive empty boxes, complete with barcodes, in certain storerooms around the US).

Eventually, we cobbled together our Frankenstein’s monster with acquired parts in my garage. And it did not work. At all. As much as we knew about instrumentation, we had a great deal more to learn. We went back to the drawing board and acquired yet more parts (a challenge with zero money in our bank accounts). At the same time, we started discussions with investors – “We have this great new technology that works…” And we reached out to TOF-MS manufacturers (we knew that a triple quadrupole wouldn’t cut it because we needed the whole spectrum from every laser shot). Tofwerks caught our eye – and we caught theirs (at least with “the theory”).

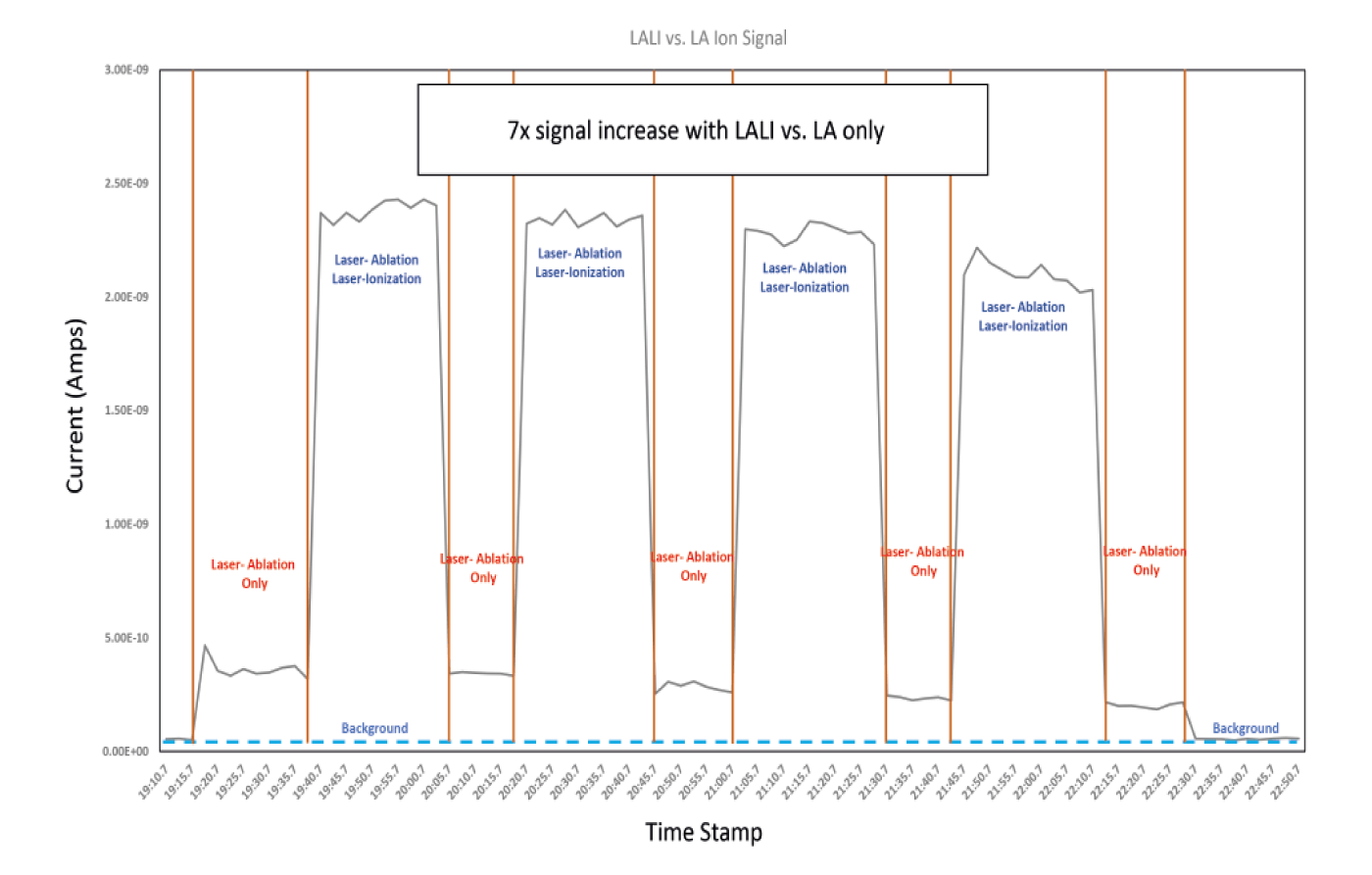

We finally cobbled together the second prototype, which we couldn’t find the courage to test; we couldn’t take a second huge disappointment. But we could only take potential investors and partners so far on promises – “Show us the data!” It was crunch time; we had a big meeting scheduled with Tofwerks on a Thursday, so on Wednesday night we decided that we needed to bite the bullet – we simply had to align the lasers (and the planets), turn it on, and see what happens… And for the first (and only!) time in Exum Instruments’ history, everything worked right off the bat. We saw a massive spike of ions to prove how efficient the LALI system was – and we obtained data for a single figure (see Figure 1).

That single captured moment changed everything. We had proof of our promise. Tofwerks were impressed and jumped on board. The investors were impressed that we’d hooked Tofwerks with our system’s technical merits, so they jumped in. As did a laser manufacturer…

I was not the world’s best school kid – I did just enough to get by. I wasn’t scientifically or mathematically driven. Rather, I was the rebellious skater/artsy kid at the all-boys catholic school. Almost inevitably, I became a graphic design and studio art major (a long way from mass spectrometry). I also got seriously into rock climbing and, at some point on an ascent, had an epiphany: “Wow. Rocks are really cool!” Why is granite different to limestone? What are all these layers? For fun, I took a crash course in planet science and was fortunate to have an amazing professor who got me even more excited about rocks. Suddenly, I wanted to become a geologist. I also realized I enjoyed – and had an affinity for – chemistry through some introductory courses and yet another amazing professor at community college. (Sidenote: I’d like to give a big shout out to community colleges. They get such a bad rap, but they were home to some of my best teachers). I loved geology and a loved chemistry – and I wondered if there was a way to marry the two. Is geochemistry a thing?

A few twists of fate later, and I found myself on a tour of the MagLab (the National High Field Magnetic Laboratory) in Tallahassee, Florida with Munir Humayun (still the smartest and most genuinely enthusiastic person I have ever met) and I knew I had to work there. I asked if there were any undergraduate research positions available – “Unfortunately, not.” But I wouldn’t take no for an answer and offered to work for free. “I’ll even do the worst job ever...”

“OK. I’ve got the worst job ever,” said Munir who had been involved with the NASA Genesis mission. When the sample-return probe crash landed, the team salvaged a mixture of paint and precious metals chips. And my first ever chemistry project was to figure out how to dissolve the paint and not the metal. In other words, rather than watching paint dry, I was tasked with watching paint dissolve – for weeks. I believe it was a test of my mental resolve.

I passed the test and finally got into some real projects – laser ablation, meteorites… And I realized I’d fallen in love again: cosmochemistry. After perhaps the most productive year of my life at the MagLab, I headed off to grad at the University of New Mexico (studying under Zachary Sharp), where I moved onto tracking elements to unravel the mysteries of early solar system formation. I even got to work on Curiosity Rover data. I also used a whole bunch of cutting-edge instruments – but, despite their supposed advanced nature, I started thinking: “There must be an easier way.”

We had graduated from my garage to my basement. We had just enough money to keep ourselves alive and plan the next prototype, which Tofwerks agreed to design and manufacture for us in Switzerland. I joined the team there for a month to help put the new instrument together, and then brought it back home. Suddenly, we were pumping out real data – and demonstrating detection limits down to parts per billion; we were competing with an LA-ICP-MS on our second (working) attempt. The investors believed we had a viable product and wanted to push forward. Despite Oleg Maltsev (see sidebar: Ode to Oleg), Steve Strickland (now CFO), and I wearing multiple hats to drive the business forward, it was time to bring in some fresh talent (two mechanical engineers for starters) – especially given the task ahead.

We had the ultimatum of a lifetime. We wanted to transition from our Swiss-made prototype (September 2019) to a full product launch at Pittcon in Chicago (March 2020). Anyone working in the instrument manufacturing business will understand the level of ambition/stupidity. We laid everything out on a Gantt chart; it was technically possible – if everything went perfectly. Nothing went perfectly. One example: we had been quoted an eight-week lead time on the sample stage we needed from Germany; however, when placing the order the lead time had jumped up to 18-weeks – to a date after Pittcon. I begged, pleaded, and compromised to confirm delivery in 16 weeks – the day of Pittcon. We ended up shipping the stages directly to the exhibition floor… Other examples: exploding power supplies, partner delays, last-minute sample chamber modifications…

If you attended Pittcon, you may know that we achieved our goal. We went from another Frankenstein-esque prototype to a beautiful (if I may say so) product, complete with touch screen interface and software platform, in an incredibly short timeframe. I can’t say how proud I am of the team. Right up to Pittcon, we had all been working insane hours for months – driven by our belief that it was possible. Looking back, it was a really cool experience. I hope we never have to do it again! I want to say a special thank you to Lacy, Steve, Oleg, Cole, Gurpreet, and Jon for the stupid amount of work you all did to make it happen. Exum would not be where it is today if it weren’t for your crazy work, creativity, and ability to have fun at the same time.

We pulled out all the stops to get to Pittcon with a fully functional instrument (admittedly with last minute Dremel and double-side tape modifications). But that deadline took on a whole new meaning as the true nature of COVID-19 began to play out. As the world transitioned into lockdown, we were so grateful for the momentum we had been able to generate in Chicago. Little did we know then that there wouldn’t be another opportunity for a live, in-the-flesh launch for many months (even Pittcon 2021 will be virtual, if you haven’t heard the news).

On the exhibition floor, we were amazed by the responses and reactions we received – and the whole Exum team was there to enjoy the moment. It was really fun to watch the dawn of realization on people’s faces: “Wait – what? That’s a TOF mass spec – and it does solid samples?!” Instrument manufacturers tend to display their systems on cabinets to hide the ugly stuff – additional power supplies, roughing pumps, solvent reservoirs. We had our instrument on a table and people kept asking, “So, what’s under the table?”

"Nothing!” we’d exclaim with a sort of magicians reveal, while noting the single power cord. Visitors marveled at how compact it was and how intuitive the integrated touch screen felt. And then we’d show them the super clean mass spectra – and they would be blown away.

We wanted the Massbox to feel like a revolution. And so the genuine surprise – sometimes even confusion about how we achieved so much in such a small box – felt like a real validation of the original concept. And because we had the chance to chat with scientists from all sorts of backgrounds, we were suddenly looking at a whole host of application areas that hadn’t even crossed our minds. The future looked filled with potential and opportunities. It felt like a celebration.

Then COVID-19 hit with full force. And we felt so grateful to have worked so hard to hit the Pittcon deadline. We had already established Exum Instruments as a company and introduced the Massbox. As the pace of life slowed, we had ample time to follow up on conversations and leads from early March. And the interest generated at Pittcon inspired us to set up a virtual lab, where we can run people’s samples live on the instrument and send the data directly to their inbox. Over the intervening months, we’ve got into all sorts of interesting application development directions – several sparked by those initial Pittcon discussions.

Prior to our Pittcon launch – and very fortunately for us – we had already been doing some soul searching about target markets and application areas. Initially, we were really focused on the energy sector – oil and gas specifically. But we were getting a lot of early interest from other industries and we had started to question our initial assumptions: was oil and gas really the best fit? Post Pittcon, mid pandemic – and as oil slid into negative value in the States – we were pleased that we had broadened our analytical scope for Pittcon! The pharmaceutical industry is one exciting avenue – as is the rapidly emerging world of cannabis testing, where we can bring speed and simplicity to trace metal analysis. Metallurgy and material science is another good fit for the low limits of detection and high precision of our technology; scientists may want to characterize a special indium alloy on a manufacturing line, for example.

COVID-19 made the world a different place (and “normal” is still some way off). Despite the clear downsides of living with a pandemic, people seem to have been a little more open to alternative approaches and innovation. We’ve been given an unusual opportunity to interact with potential users while they’ve had a little more time to stop and think about cool, new technology and smarter routes to the analytical data they need.

Meanwhile, we’ve also had the time to tweak and perfect the instrument (sticky tape and rotary tools no longer required).

We have actually completely redesigned the instrument two more times since the version at Pittcon. It’s now very much production ready and continues to surprise us with its capabilities, and so we’ve had some amazing experiences doing digital demos with customers. In fact, as of writing, we’ve now sold two instruments – just seven months after the initial launch of the prototype (and in a pandemic). We also received a $250,000 grant from the state of Colorado. In all honesty, there is too much excitement to fit into a single article; maybe I’ll write part II in a couple of years to get you up to speed… We know that we still have a long way to go to become the full vision of Exum, but we are eager and determined to face the challenges ahead.

Oleg Maltsev – one of Exum’s cofounders – is amazing. He can do it all. Anything you can think of, Oleg has done – perfectly. From hi-fi stereos to exceptional carpentry to crazy electronic gadgets, his garage is full of interesting, ongoing projects. In fact, Oleg designed our entire electronics system from scratch (he had experience making tube systems for guitar amplifiers, so understood signal processing and figured he could turn his hand to it!) Today, Oleg is our director of software engineering and integration (having taught himself programming…). He is a true renaissance man. Thank you, Oleg!

Many people will be delighted to wave goodbye to 2020 for very good reasons. At Exum Instruments, we’ll always view 2020 as a year of real highs and lows. And we are absolutely looking forward to 2021 and all the surprises and challenges it may bring.

Looking back over the past year or two, one important lesson springs to mind: ignorance is not just bliss, it’s super important – especially for budding entrepreneurs and inventors. If I knew then all that I know now, I’m not sure I would have had the strength to face the mountains ahead. But I also recognize that the failures made the successes possible. No doubt the coming year will also see its fair share of both – but that’s life, I guess.

Here’s to a more enlightening, more empowering, more enriching, and, of course, safer and healthier 2021!