Why is polymer analysis important?

Polymers are widespread compounds found in both natural and synthetic products – synthetic polymers mainly come from the petrochemical industry. One example of a seemingly simple product partially made of biopolymers? Gummy bears!

What are the main challenges of polymer analysis?

Polymer analysis tends to be complex because, in most cases, polymers are not simply made up of uniform long molecules, but a mixture of molecules with different molecular weights and functionalities. Increasing the complexity further, polymers are often mixed with many other small molecules, including sugars, acids, vitamins, and colors. Gummy candy is a good example of this complexity, comprising sugars (sometimes maltodextrin), small amounts of flavoring, (bio-)polymers to keep the structure of the product, and packaging – which can impact the final consumed product.

And what is the best way to analyze gummy bears?

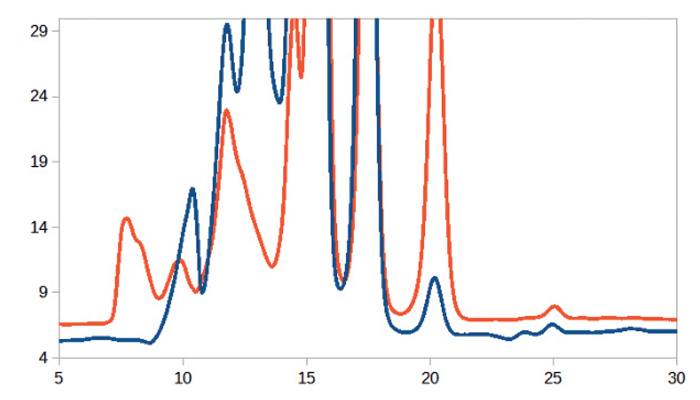

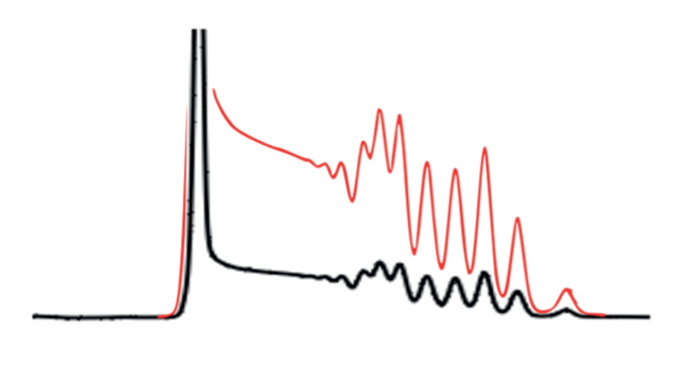

In our experience, gel permeation chromatography (GPC), size exclusion chromatography (SEC) and ion exchange chromatography are among the most successful, easy, and reproducible approaches to analyze complex food matrices. In Figure 1, we show separations of two different gummy candy suppliers – for sugars and maltodextrin – to illustrate. The second figure demonstrates a quality check for the ingredient maltodextrin.

However, the main challenge with these separation modes is the type of solvents used, which tend to be organic and apolar solvents or salty solvents. The instruments need to be built to withstand these conditions.

For the past 13 years, AppliChrom has relied on KNAUER equipment – not only for HPLC, but also for GPC/ SEC separation methods. Why? Because of its excellent stability and longevity with aqueous salty solvents and organic solvents, such as CHCl3, THF, Acetone, DMSO, NMP, DMF, DMAc.

You also mentioned the analysis of packaging materials. Can you give us an example?

Sure. GPC is suitable for the analysis of the plastic material used to pack the gummy candy and the glue that is used to seal the package. The packaging should contain no small molecular residues. For quality testing of the glue, GPC can be used to ensure the activity measured by the content of small molecules. We used two AppliChrom StyDiViBe columns (1500A for 100–120 000 Da; 10E5 Multipore for 100–1 Mio Da) at 20 °C, under THF elution conditions and refractive index detection with a KNAUER AZURA HPLC system. The result of the quality test showed no toxic residues from the glue or packaging in the final product.

How does Applichrom support the polymer and food industries?

New analytical challenges always represent the beginning of a journey. For example, a user might start with a GPC/ SEC separation, but soon they have to cover extra fields in HPLC. AppliChrom, in partnership with KNAUER, can offer complete solutions – equipment, material, methods, and expertise – to cover the whole range of applications, with effective communication and cooperation.

For more information, visit www.knauer.net and www.applichrom.de