Helium is an inert gas that is obtained from natural gas well sources where helium recovery infrastructure is installed. Over several decades, helium has evolved to be the GC carrier gas of choice because of its availability and good chromatographic performance. This has most notably been the case for GC-MS using electron ionization (EI) and instruments have been optimized for its use. But helium is non-renewable; its availability is linked to petroleum production and therefore to the vagaries of that troubled market. Additionally, helium is under high demand in a number of areas including medical diagnostics, which often take a priority over chromatographic use. As a consequence, the global helium infrastructure is facing great challenges, including geopolitical influence, natural events, dwindling sources, and technical issues at extraction facilities.

In short, helium availability is severely impacted, which ultimately means increasing costs and increasingly a lack of availability for end users.

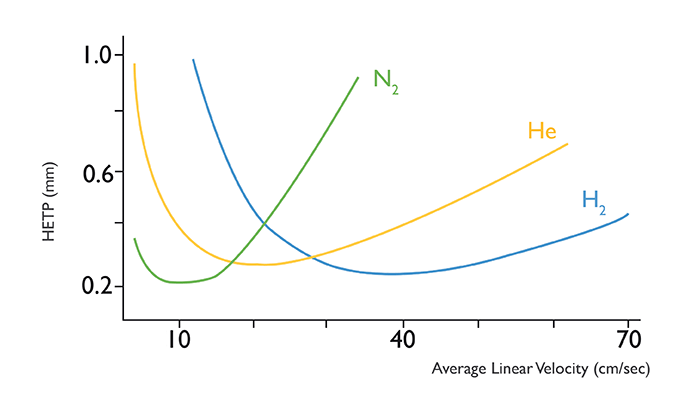

The increasing pressure of the helium shortage has led many to consider other options. We have seen increased use of hydrogen and nitrogen as alternative carrier gases. Hydrogen’s optimum linear velocity is greater than helium, which can increase sample throughput through decreased analysis times. However, its combustible nature and general safety concerns have hampered its adoption. Additionally, hydrogen is a reducing gas and often results in chemical changes of fragmentation ions which can negatively impact operation in mass spectrometry. And finally, the use of hydrogen can cause discrimination and other issues related to its reactivity in the injection port of the GC as well.

Nitrogen has been described as a “slow gas” because its optimum linear velocity is lower than helium, and is often overlooked as a helium alternative, due to historic issues which are no longer limitations. In GC-MS applications, many commercial systems have evolved to using helium and electron ionization which occurs in vacuum. For successful operation, high vacuum must be maintained, and instruments and vacuum pumps have been optimized for helium gas operation for most manufacturers. This leads to an issue when they might consider nitrogen as a possible replacement gas as a result of helium supply concerns.

But when we utilize atmospheric pressure ionization for ion formation, the downsides of nitrogen disappear. In atmospheric pressure gas chromatography (APGC) – where we are dealing with a high-pressure environment for ionization – the presence or absence of nitrogen as the GC carrier gas makes no difference to either sensitivity or noise. Additionally, the atmospheric chemical ionization process already utilizes nitrogen for the initial formation of charged species. Therefore, use of nitrogen as the carrier gas actually simplifies the system because we are only introducing nitrogen from an additional source through the column, effectively removing helium from the equation altogether.

Although the coupling of GC and MS with atmospheric pressure ionization (API) appeared in published papers as early as the 1970s, the commercial interest in coupling GC with an atmospheric pressure ion source has only expanded in the last decade. The need to preserve highly diagnostic molecular ions for some applications has made “soft” ionization (which causes less fragmentation) more desirable than “hard” ionization techniques that can extensively fragment molecules but are, nevertheless, the expectation with traditional GC-MS. The crux of the matter is that reduced fragmentation yields higher sensitivity and specificity, simplifying precursor ion selection for targeted MS/MS applications using MRM acquisitions.

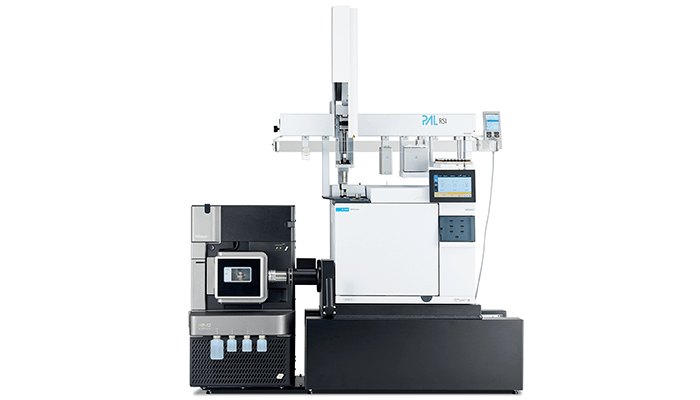

At Waters, we promote APGC as an ion source for multiple models of mass spectrometer. Options exist for highly sensitive GC-MS/MS performance as well as high-resolution and even ion mobility separations. Furthermore, it is straightforward to swap between APGCMS and UPLC-MS in a matter of minutes. For this, no venting is required, and LCMS and GC-MS can be performed using the same mass spectrometer. Finally, it’s worth noting that APGC analysis are not flow-rate limited as is the case for most EI-based GC-MS systems. This allows for a wider range of compatibility for GC column flow and carrier gas type.

These new systems provide us with a range of unique, data-rich experimental capabilities, giving analytical platforms a greater reach than ever before. Using APGC, we can harness a combination of sensitivity, mass accuracy, resolution, and ion mobility to give levels of selectivity that will thoroughly characterize samples and yield data at an entirely different and exciting level.

In short, APGC is robust, sensitive, and very well suited to the identification and determination of a wide variety of compounds. With APGC, unlike EI, the molecular ion is typically well preserved, resulting in higher sensitivity and selectivity. Then, of course, there is the cost. The ability to use nitrogen as the carrier gas has an immediate impact on costs and this alone is a big driver for adopting APGC. If you’re not concerned about cost (congratulations), you probably are worried about the volatility of the helium supply chain; the supply-and-demand equation is certainly tipped heavily toward demand. We’ve seen suppliers limiting the volumes of helium sold to any one laboratory, making it increasingly important for labs to have alternative options to ensure effective and agile responses to supply chain interruptions.

We are now beginning to see other manufacturers looking to API techniques and, although they are a little less mature than ours, we anticipate rapid growth over the next decade. Due to the combination of positive performance characteristics of APGC we fully expect the rapid growth in use of the technique across the coming decade.

We can find a good analogy for APGC in the LC-MS world, which began using electrospray ionization to the point where, with MS/MS in particular, it became the gold standard for small molecule analysis. Why? Because ESI delivered high sensitivity and specificity for MS/MS. APGC looks set to follow the same path – and the helium issue will simply act as a catalyst. Overall, APGCMS/ MS offers an affordable, well-suited alternative to GC-MS/MS with electron ionization for the determination of organic compounds at ultra-trace levels.

There will be some inertia to overcome – as with any new technique! There is an inherent resistance to change but, as APGC continues to be incorporated in published methodologies, we will see increasing adoption in more applications and more laboratories. Moving from EI to API is a big step change – and moving away from tradition involves a strong belief in the technique and a willingness to invest in retraining and in new or modified instrumentation. Luckily for us, the latter two are low bars, whereas leaving decades of experience with EI to support the “new kid on the block” requires a somewhat higher leap of faith! Much of people’s understanding of any given process is also directly related to the limitations of the original technique, and this understanding is often slower to change than the techniques themselves.

Final thoughts

The APGC system is a significant step up in terms of analytical performance relative to what we can currently achieve with EI systems. It represents a change in technology that aims to alleviate some of the biggest challenges the field currently faces. And, specifically with respect to helium shortages, APGC offers a simple plug-and-play solution for swapping to nitrogen – an affordable, renewable alternative that delivers results without any analytical compromise. We truly believe it is a gamechanger – and we hope users will, too.