Credit: FHI

Turning carbon dioxide (CO2) into valuable chemicals, such as ethylene and ethanol, is a key goal in sustainable energy research, and a new study has uncovered critical insights into how copper-based catalysts can drive this transformation more efficiently. By combining surface-enhanced Raman spectroscopy (SERS) and computational modeling, the researchers identified the specific intermediates and active sites on copper surfaces that are responsible for converting CO2 into multi-carbon products – potentially leading to the design of more effective catalysts for industrial applications.

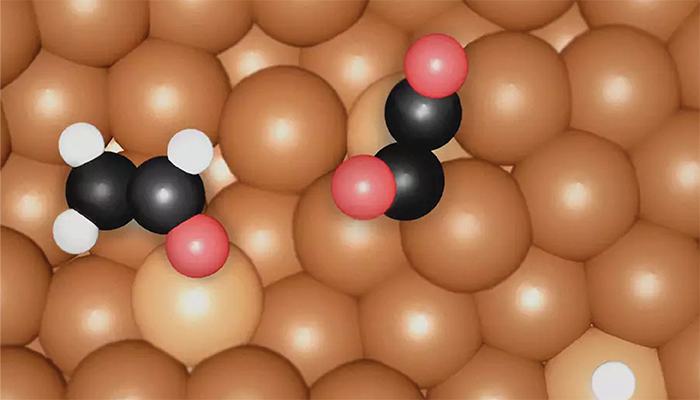

The study focused on understanding how CO2 is converted into ethylene and ethanol on copper surfaces. Copper is known to be an effective catalyst for this reaction, but the exact mechanisms at play have been elusive. The researchers were able to pinpoint the formation of specific intermediates, such as *OCHCH2, which plays a crucial role in the pathway leading to ethanol. They also identified the conditions under which these intermediates form, including the importance of surface defects and the presence of undercoordinated copper sites.

Using SERS to detect subtle vibrational changes on the copper surface, the team observed the formation of CO dimerization and subsequent intermediates, providing real-time insights into the reaction process. By adding density functional theory (DFT) calculations, the team were able to provide a comprehensive understanding of the CO2 reduction process, revealing that the morphology and electronic structure of the copper catalyst play pivotal roles in determining whether CO2 is reduced to ethylene, ethanol, or other products.

Determining the precursor responsible for ethanol formation, *OCHCH2, was very tricky, according to Federico Dattila, co-author of the study and Marie Skłodowska-Curie Post-doctoral Fellow. "This intermediate occurs after the suggested rate-determining step for C2+ formation, i.e. its further reduction to ethanol should be very fast," he says. "Low surface concentration of *OCHCH2 are then expected, below the sensitivity of standard surface-enhanced Raman experiments. That explains why this intermediate was not observed prior to our study. The oxide-derived copper nanocubes synthesized in this work allowed a higher Raman sensitivity, which resulted in the observation of the intermediate."

This deeper understanding could inform the design of next-generation catalysts that are optimized for specific reactions, improving the efficiency of CO2 utilization in industrial processes.

"The production of multi-carbon chemicals such as ethylene and ethanol via electrochemical reduction of CO2 is currently an unselective process, as both products occur simultaneously," says Dattila. "Starting from our insights, researchers in academia and industry could devise a new class of catalysts only selective to ethanol, for instance increasing surface strain or oxophilicity. Specifically, surface strain can be increased by synthesizing smaller nanoparticles, while oxophilicity can be improved with the insertion of oxophilic sites (such as Sn, Al, Ru in the copper matrix)."