The problem

The resolving power provided by contemporary 1D- and 2D-LC technology is insufficient to tackle the complex sample mixtures encountered in modern life-science studies, where each sample may contain hundreds of thousands of proteins. Furthermore, when high-peak capacity separations can be realized, it is often only achieved at the expense of very long analysis times, making the technology intrinsically unsuitable for biomarker discovery and validation studies.Background

Since the introduction of the first commercially available HPLC column in the early 1970s, there has been a trend towards using smaller particles to increase the separation efficiency and sample throughput. Using state-of-the-art packed columns operated at ultra-high-pressure conditions, the maximum peak capacity of high-resolution one-dimensional LC is currently limited to about 1,000 in a few hours (1). To boost separation performance, two-dimensional liquid chromatography (2D-LC) separation technology has been developed. Conventional on-line 2D-LC separations are performed by coupling two columns using a high-pressure switching valve to modulate fractions eluting from the first-dimension (1D) column and directing these to the second-dimension (2D) column. Provided orthogonal separation mechanisms are employed, the maximum peak capacity that can be realized is the product of the two individual developments. In this way, LC×LC separations yielding peak capacities of up to 2,100 in 60 min have recently been developed (2). However, a disadvantage of conventional 2D-LC is that the fractions collected are analyzed sequentially.The solution

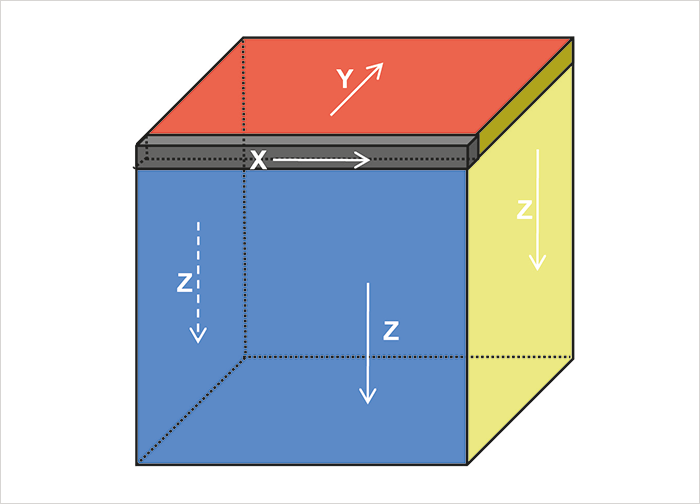

Several years ago, Peter Schoenmakers from the University of Amsterdam, the Netherlands, explained a new chromatography concept to us, with the potential to deliver unmatched separation performance in terms of the maximum peak capacity and peak-production rate – spatial 3D liquid chromatography (3D-LC). Spatial 3D-LC separations are performed by forcing analytes to migrate to different positions in a 3D body (see Figure 1). In brief, after injecting the sample mixture into one corner of the device, three subsequent separations take place in the X, Y and Z directions, which means that each peak is characterized by its X, Y and Z coordinates in the 3D separation body.

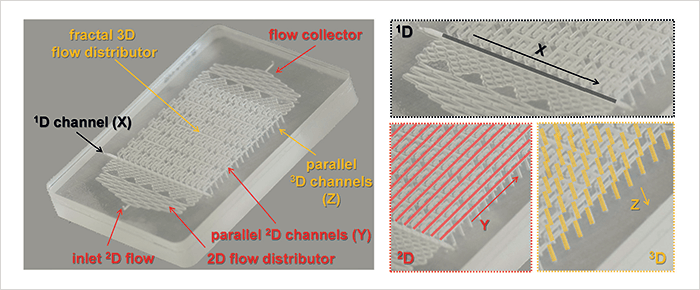

We strongly believe in the potential of spatial multi-dimensional LC; together with Schoenmakers, patents were filed describing various aspects of the 3D separation body, including flow control elements and detection. At the Vrije Universiteit Brussel, we have been developing the microfluidic chip technology necessary to realize spatial 3D-LC separations since 2010. In that time, we have delved into many different aspects of the technology and how it can be applied in prototype chips. One such prototype chip for spatial 3D-LC developed in our lab is depicted in Figure 2. The concept is easy to grasp with a cube in mind: after finalizing a 1D dimension separation in the X direction, the 2D separation stage is performed simultaneously in 16 parallel Y channels. In a final step, all the compounds situated in the X–Y plane are separated in 254 parallel 3D channels (Z direction). The maximum peak capacity (3D-LCnc) that can be realized is the product of peak capacities (nc) achieved in the three individual separation stage, according to: 3D-LCnc = 1nc × 2nc × 3nc Crucially, because of the parallel nature of the separations in the second and third dimensions, the total analysis time (3D-LCtime) is only the sum of the three separation stages: 3D-LCtime = 1time + 2time + 3time

The upshot is that the analysis time is greatly reduced with spatial 3D-LC when compared with conventional coupled-column multidimensional approaches, in which sampled fractions are analyzed sequentially. But getting there is no simple task. One major challenge was the need to address flow control during subsequent separation stages. To that end, we explored the use of physical barriers to confine the flow between the individual stages, and controlled flow with 2D and 3D flow distributors (3),(4). We also needed to demonstrate proof-of-principle when it came to creating polymer-monolithic stationary phases in-situ in the microfluidic chip. To confine monolith formation to the desired location, we developed a UV-initiated polymerization approach in combination with the application of photomasks.

Beyond the solution

Many challenges remain in the full realization of this spatial 3D-LC concept. For example, flow control can still be improved, orthogonal retention mechanisms should be established, and detection is currently a bottleneck. To address the latter problem, it is envisioned that detection of analytes can be realized via a ‘printing technique’, which is to say by immobilizing the effluent from the final separation on a suitable substrate at regular intervals. The result of the 3D separation will be a series of 2D time images, from which 3D images can be reconstructed after (mass spectrometric) imaging. Recently, Jelle De Vos obtained a postdoctoral grant from the Research Foundation Flanders to extend our research and further develop spatial 3D-LC technology. But we are also open to establishing collaborations with both academic groups and industry partners to join us in our journey from concept to three-dimensional reality.Jelle De Vos is a postdoctoral researcher and Sebastiaan Eeltink is a research professor at the Vrije Universiteit Brussel (VUB), Department of Chemical Engineering, Brussels, Belgium.

References

- PJ Eugster et al., “Peak capacity optimisation for high resolution peptide profiling in complex mixtures by liquid chromatography coupled to time-of-flight mass spectrometry: Application to the Conus consors cone snail venom”, J Chromatogr A, 1259, 187–199 (2012). DR Stoll et al., “Fast, comprehensive online two-dimensional high performance liquid chromatography through the use of high temperature ultra-fast gradient elution reversed-phase liquid chromatography”, J Chromatogr A, 1122 123–137 (2006). B Wouters et al., “Design of a microfluidic device for comprehensive spatial two-dimensional liquid chromatography”, J Sep Sci, 38, 1123–1129 (2015). B Wouters et al., “Towards ultra-high peak capacities and peak-production rates using spatial three-dimensional liquid chromatography”, Lab on Chip, 15, 4415–4422 (2015).